Two-stage oily sludge pyrolysis reaction device

A technology for pyrolysis reaction and sludge, which is used in pyrolysis treatment of sludge, petroleum industry, special forms of dry distillation, etc. It can solve the problem of sticking or even deformation in the viscous zone of sludge, obvious thermal hysteresis effect, and low heat transfer efficiency. problem, to achieve the effect of large feed adaptability, prolong reaction time and improve pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

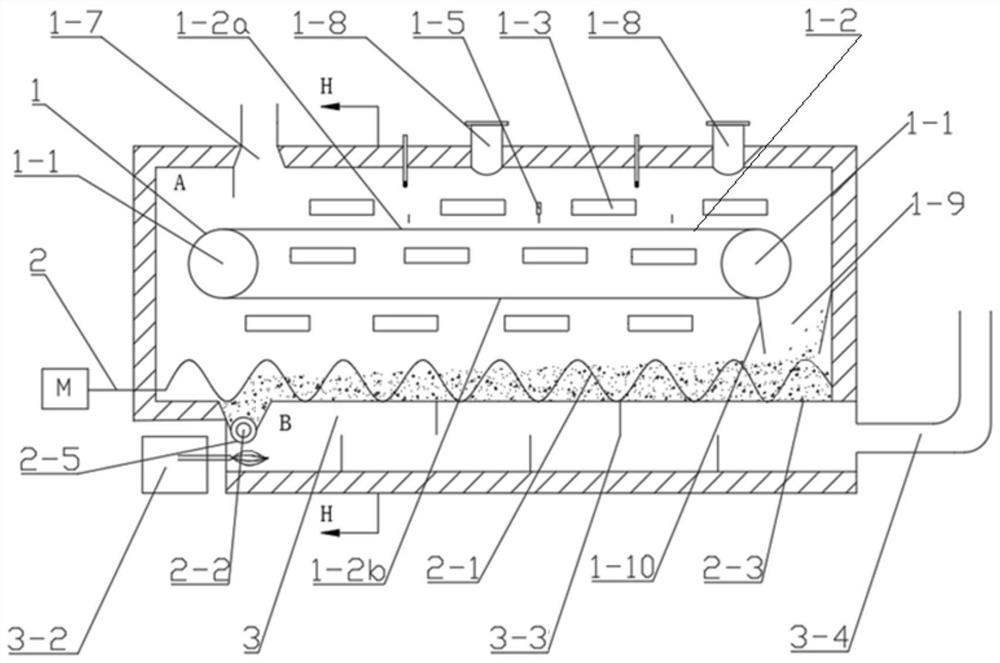

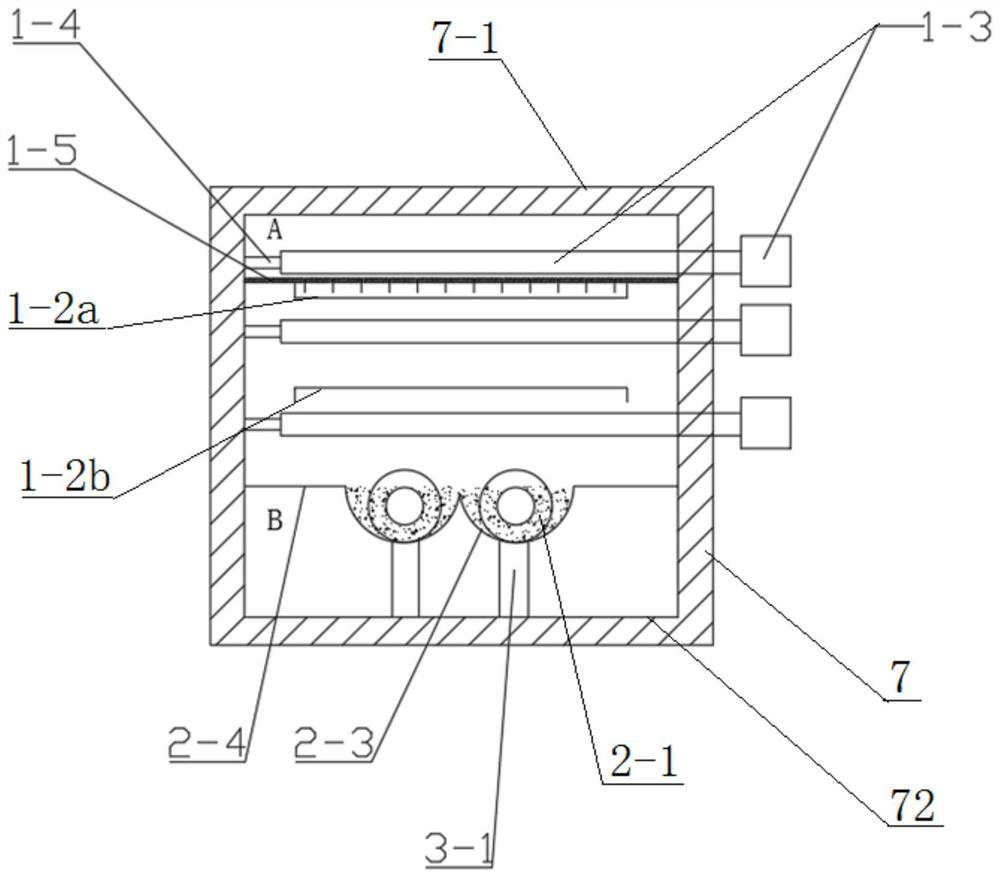

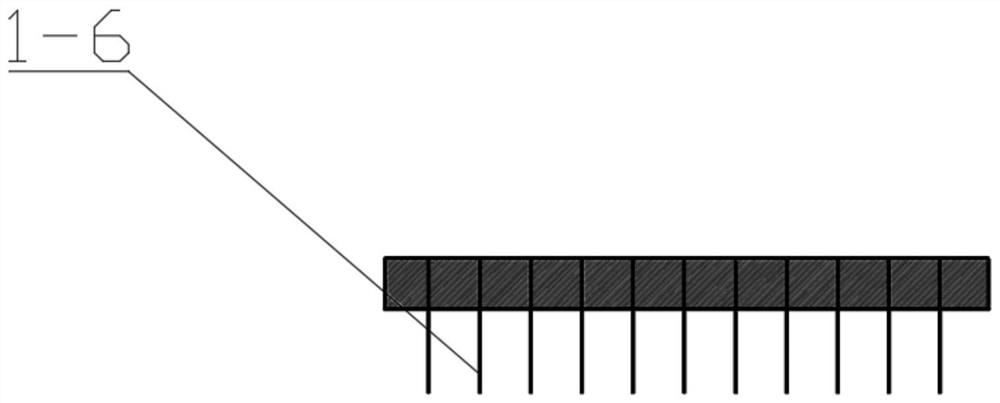

[0039] A two-stage pyrolysis reaction device for oily sludge such as figure 1As shown, it consists of the upper chain plate reactor 1 and the lower auger reactor 2. The upper chain plate reactor 1 is equipped with a transmission assembly for carrying materials to move. The transmission assembly includes two transmission sprockets 1-1 rotatably connected to the chain plate and a chain plate 1-2 built on the two transmission wheels. The two transmission sprockets 1-1 are respectively located at both ends of the upper chain plate reactor 1 to tension the chain plates 1-2, and the chain plates are arranged horizontally along the moving direction. Radiant tube heaters 1-3 are arranged between the upper chain plate 1-2a of the upper chain plate reactor 1 and the furnace roof, and the radiant tube heaters 1-3 are evenly distributed at a certain distance along the running direction of the chain plate. The mouth end is installed on the inner wall of one side of the furnace, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com