Ceramic handicraft manufacturing process based on cotton fiber medium

A technology for making crafts and handicrafts, applied in the field of porcelain handicrafts, can solve the problems of insufficient ornamental, weak three-dimensional sense of decorative parts, easy to cause damage, etc., and achieve the effect of improving ornamental, cultural connotation, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

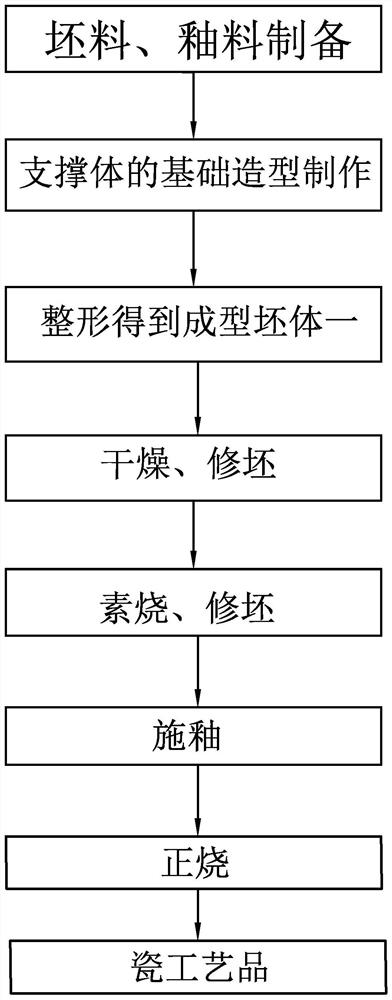

[0030] Such as figure 1 Shown, be the manufacture process of porcelain handicraft of the present invention:

[0031] 1. The formula of the blank is 25-30% of kaolin, 25-30% of purple gold clay, and 25-40% of Longquan porcelain clay. The slurry is passed through a 325-mesh standard sieve to obtain a blank with a moisture content of 30%-33%, and the water glass is used to adjust the moisture content of the blank. Consistency: Longquan porcelain clay has a high SiO2 content, which can prevent the decorative body from cracking and reduce firing shrinkage. If the moisture content of the blank is too low, there will be less blank attached to the cotton fabric, which is not only difficult to shape, but more importantly It is that the strength of the decorative body part in the porcelain handicraft is not enough.

[0032] The formula of the glaze is feldspar 0-7%, quartz 0-15%, frit 70-90%, clay 5-10%, talc 5-10%, Longquan porcelain clay 25-30%, and the moisture content of the glaze ...

Embodiment 2

[0039] Embodiment 2 is roughly the same as Embodiment 1, the difference is that the cotton fabric of Embodiment 2 adopts lace fabric, and the lace fabric is lace-like, with a mesh diameter of 0.6mm and a grid area of 1.6×1.6mm 2 , for the grid blocked by the billet, use blowing or other methods to blow off or dig out the excess billet; the glaze method for forming the third body is spraying glaze, and a small amount of spraying glaze method is used, and it is dried after spraying the glaze once , when the glaze is dry and still viscous, spray the glaze again. This process needs to be repeated about three times. Through the above method, the glaze can be stably adhered to the decorative body. In this embodiment, the inclination angle between the lace fabric and its horizontal plane is greater than 45°.

Embodiment 3

[0041] Embodiment 3 is roughly the same as Embodiment 2, except that the formula of the blank is kaolin 45-50%, quartz 5-10%, feldspar 10-15%, Suzhou soil 6-8%, and Longyan soil 12-15%. The content of Fe2O3 in kaolin is low, and the white purity of porcelain handicrafts after firing is high. The formula of the glaze is: frit 60-70%, feldspar 15-25%, borax 2-5%. The way of glazing in this embodiment is dipping glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com