Method and device for safely preparing dimethyl oxalate in coupling reactor and application thereof

A dimethyl oxalate and reactor technology, which is applied in the preparation of carbon monoxide or formate reaction, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as hidden dangers of methyl nitrite, and achieve safe industrial production, The effect of preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

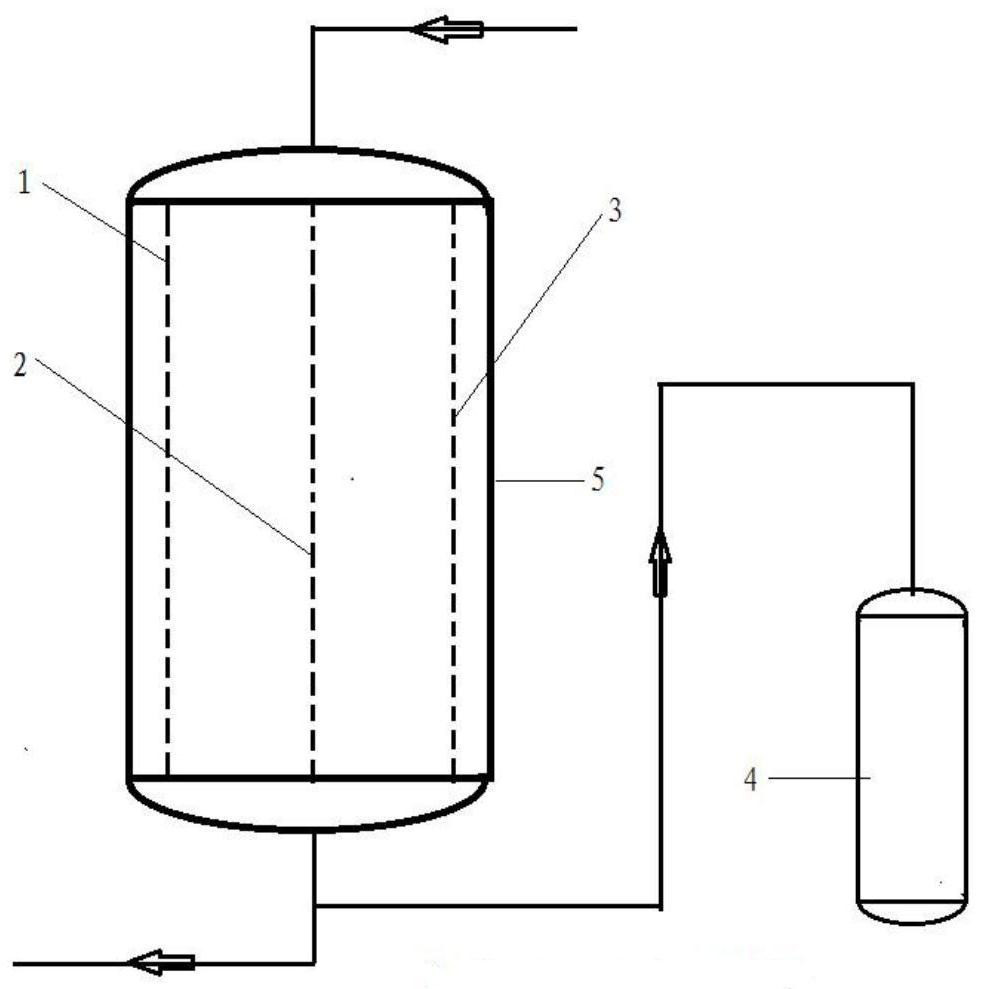

Image

Examples

Embodiment 1

[0073] The methyl nitrite coupling reaction conditions are: temperature 100° C., pressure 1.8 MPa. The volume ratio of the methyl nitrite and carbon monoxide is 1:15. The intake of fresh cooling water is (4.50v)m 3 / h, the cooling water circulation is (0.8v)m 3 / h, where v is the volume of the coupling reactor, and the temperature and / or pressure in the coupling reactor are controlled in the following manner.

[0074] When the temperature in the coupling reactor exceeds 189°C, increase the circulation of cooling water to 1.9 times of the original circulation. At the same time, when the intake of fresh cooling water is lower than 90% of the original flow, a low cooling water flow alarm is generated, and the intake of fresh cooling water is increased to 115% of the original intake. Simultaneously when fresh cooling water feed rate is lower than 80% of original flow, cut off the feeding of raw material methyl nitrite urgently.

[0075] When the temperature in the coupling rea...

Embodiment 2

[0083] The methyl nitrite coupling reaction conditions are: temperature 155°C, pressure 1.2MPa. The volume ratio of the methyl nitrite and carbon monoxide is 1:15. The intake of fresh cooling water is (4.50v)m 3 / h, cooling water circulation is (0.8v)m 3 / h, where v is the volume of the coupling reactor, and the temperature and / or pressure in the coupling reactor are controlled in the following manner.

[0084] When the temperature in the coupling reactor exceeds 185°C, increase the cooling water circulation to 1.4 times the original circulation. At the same time, when the fresh cooling water flow rate is lower than 90% of the original flow rate, a low cooling water flow alarm will be generated, and the fresh cooling water flow rate will be increased to 115% of the original flow rate; the fresh cooling water flow rate will be lower than the original flow rate. When 80%, cut off the feeding of raw material methyl nitrite urgently.

[0085] When the temperature in the coupli...

Embodiment 3

[0093] The methyl nitrite coupling reaction conditions are: temperature 185°C, pressure 2.5MPa. The volume ratio of the methyl nitrite and carbon monoxide is 1:12. The intake of fresh cooling water is (6.50v)m 3 / h, cooling water circulation is (1.3v)m 3 / h, where v is the volume of the coupling reactor, and the temperature and / or pressure in the coupling reactor are controlled in the following manner.

[0094] When the temperature in the coupling reactor exceeds 205°C, increase the cooling water circulation to 2.2 times the original circulation. At the same time, when the intake of fresh cooling water is lower than 90% of the original flow, a low cooling water flow alarm will be generated, and the intake of fresh cooling water will be increased to 125% of the original intake; the intake of fresh cooling water will be lower than the original flow When 80%, cut off the feeding of raw material methyl nitrite urgently.

[0095] When the temperature in the coupling reactor exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com