Method for improving age hardening effect of magnesium alloy

An age-hardening, magnesium alloy technology, applied in metal rolling, furnace types, furnaces, etc., can solve the problems of complicated severe plastic deformation process and long aging treatment time, which is conducive to large-scale industrial production, shortening peak aging time, The effect of improving time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: The method for improving the age hardening effect of magnesium alloys in this embodiment is implemented according to the following steps:

[0022] 1. Solid solution treating the Mg-RE-Ag-Zn-Zr as-cast alloy at 500-520°C, and quenching the as-cast alloy in water after the solution treatment to obtain the quenched as-cast alloy;

[0023] 2. Carry out single pass rolling to the as-cast alloy after quenching, obtain the as-cast alloy after rolling;

[0024] 3. Carry out aging treatment to the cast alloy after rolling at a temperature of 180°C-200°C to complete the method for improving the age hardening effect of the magnesium alloy;

[0025] Wherein step 2 controls single-pass reduction: 2-3%, rolling speed: 0.4-0.6m / s, total reduction: 12%-15%.

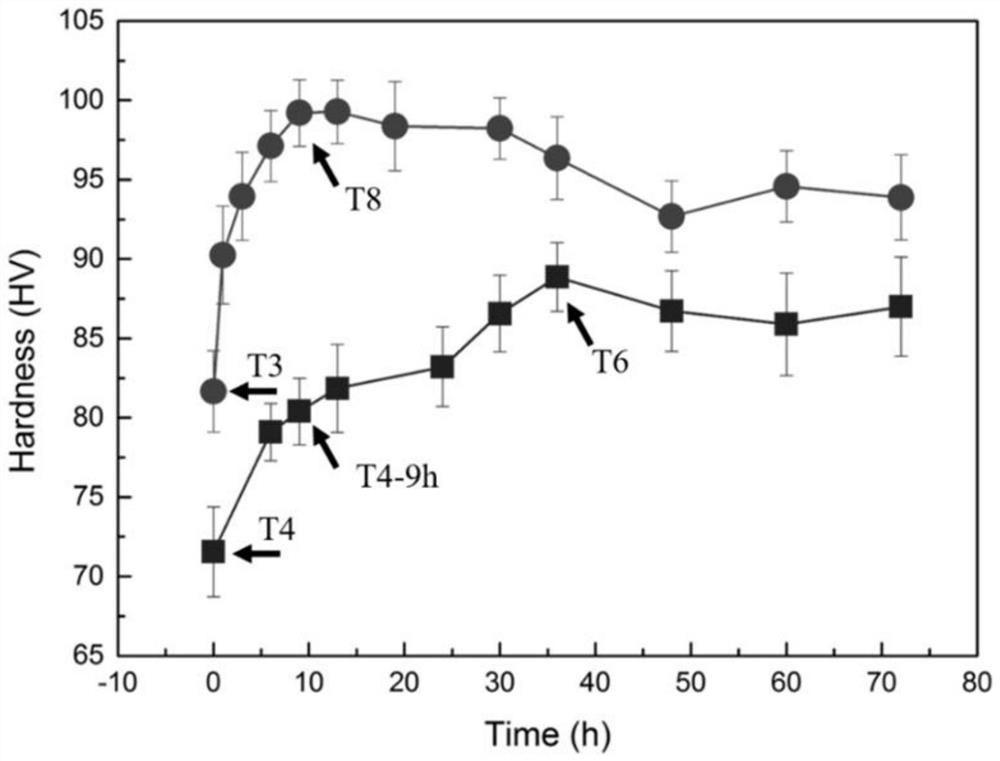

[0026] In this embodiment, after the as-cast Mg-RE-Ag-Zn-Zr alloy is subjected to solution aging, β′ and β″ precipitates, or β′ and γ″ precipitates are produced in the alloy; after pre-rolling, the Regulat...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass percent content of each element of the Mg-RE-Ag-Zn-Zr cast alloy in step 1 is: RE: 7%-15%, Ag: 0-1.5%, Zn: 0.5-1%, Zr: 0.4-0.7%, and the balance is Mg.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment two is that RE elements include Gd, Y, Nd, Ho, Er and Dy, wherein each element accounts for 100% of the mass of Mg-RE-Ag-Zn-Zr cast alloy Min content: Gd: 2-10%, Y: 0-2%, Nd: 0-2%, Ho: 0-2%, Er: 0-1%, Dy: 0-5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com