Processing technology of jet-molded high-speed steel

A processing technology, spray forming technology, applied in the field of spray forming high-speed steel processing technology, can solve the problems of reducing the overall hardness and tensile strength of high-speed steel, inconvenient recycling and processing of high-speed steel, and less precipitation of carbides, etc., to achieve slow down The effect of decreasing hardness, high tensile strength, and large overall hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

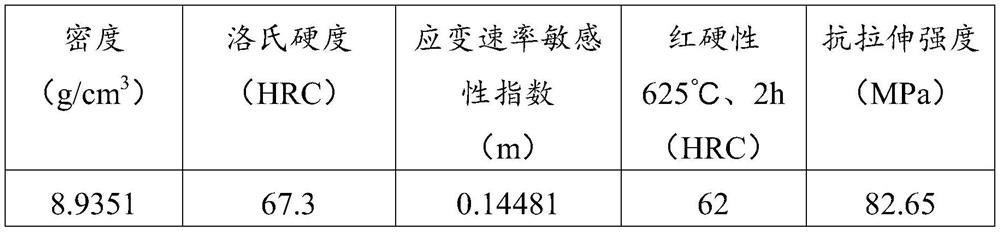

Examples

Embodiment 1

[0039] Sample preparation for the microstructure of the high-speed steel sample: use a wire cutting machine to cut the sample into small pieces, 10mm in height, and grind and polish to obtain a metallographic sample, use 4% nitric acid alcohol for corrosion, and conduct metallographic testing under a Zeiss metallographic microscope For tissue observation, the morphology of matrix and carbide was observed under FEI-Siron field emission scanning electron microscope.

Embodiment 2

[0041] Carbon replica sample preparation: mount the high-speed steel sample with cold mounting materials to make a mosaic sample, grind the sample, polish and corrode, choose picric acid as the corrosion agent, and the specific composition ratio is 1g picric acid + 5m1 hydrochloric acid + 500m1 methanol, Corrosion for 3 minutes, after the sample is corroded, carry out vacuum sputtering coating and carbon spraying. The film time and coating thickness are controlled by computer to ensure the uniformity and thickness of the carbon film. After the sample is coated, use a blade to divide the coating surface into 3mmX3mm. Square grid, using the electrolytic film removal method, the time is 5min, so that the size of the removed film is consistent with the size of the copper mesh, after the film is removed, use the copper mesh to pick up the carbon film, then wash it in alcohol, and finally dry it on filter paper That's it.

Embodiment 3

[0043] Hardness performance test: FR-3e digital Rockwell hardness tester is used, the loading load is 150kg, and the loading position is close to the center of the carbon film sample, within 1 / 2 of the radius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com