Large-scale thin-walled X-ray focusing mirror replication method

A replication method, X-ray technology, applied in the field of large-scale thin-walled X-ray focusing mirror replication, can solve problems such as low efficiency, inability to meet mass production, and inability to ensure the consistency of mass replication processes, so as to avoid irregularities , to achieve batch replication, to achieve the effect of consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

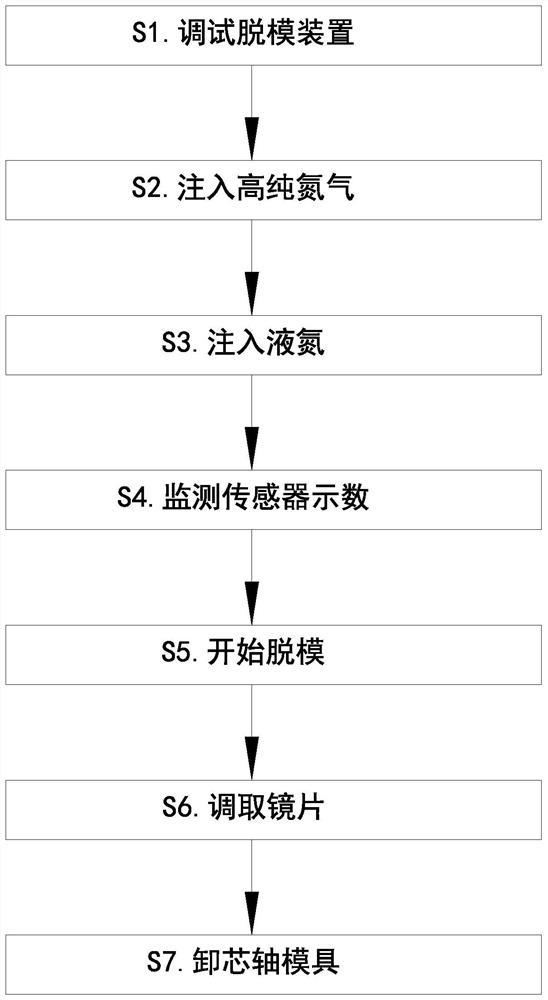

[0026] Specific implementation mode 1: refer to figure 1 This embodiment is described, which provides S1. Debugging the demoulding device; installing the mandrel mold 2 with the mirror shell, and debugging the demoulding device;

[0027] S2. Inject high-purity nitrogen; inject nitrogen into the sealing cover 1 of the demolding device;

[0028] S3. Inject liquid nitrogen; inject liquid nitrogen into the mandrel mold 2;

[0029] S4. Monitor the display of the sensor; during this process, pay attention to monitoring the display value of the force sensor, thermocouple meter, ambient temperature and humidity, and make a record;

[0030] S5. Start demoulding; remove the mirror shell from the mandrel mold 2 through the demolding device;

[0031] S6. Lift the mirror shell; lift the mirror shell through the lifting device;

[0032] S7. Unloading the mandrel mold 2.

[0033] The lifting device is in the prior art, and a device capable of hoisting the mirror housing can be used.

specific Embodiment approach 2

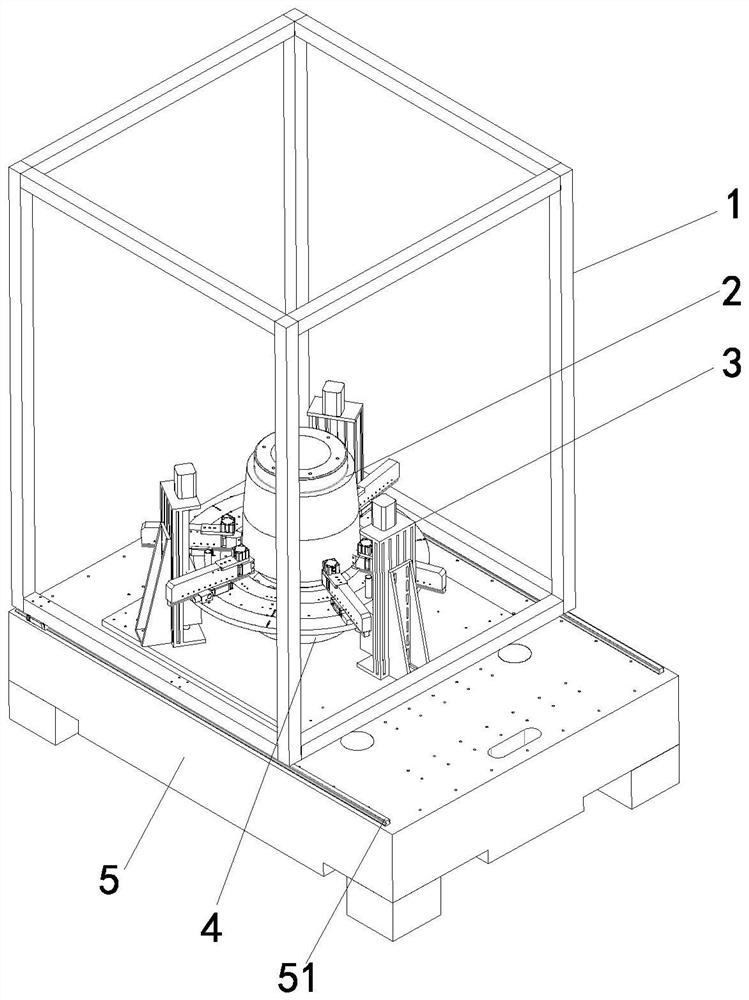

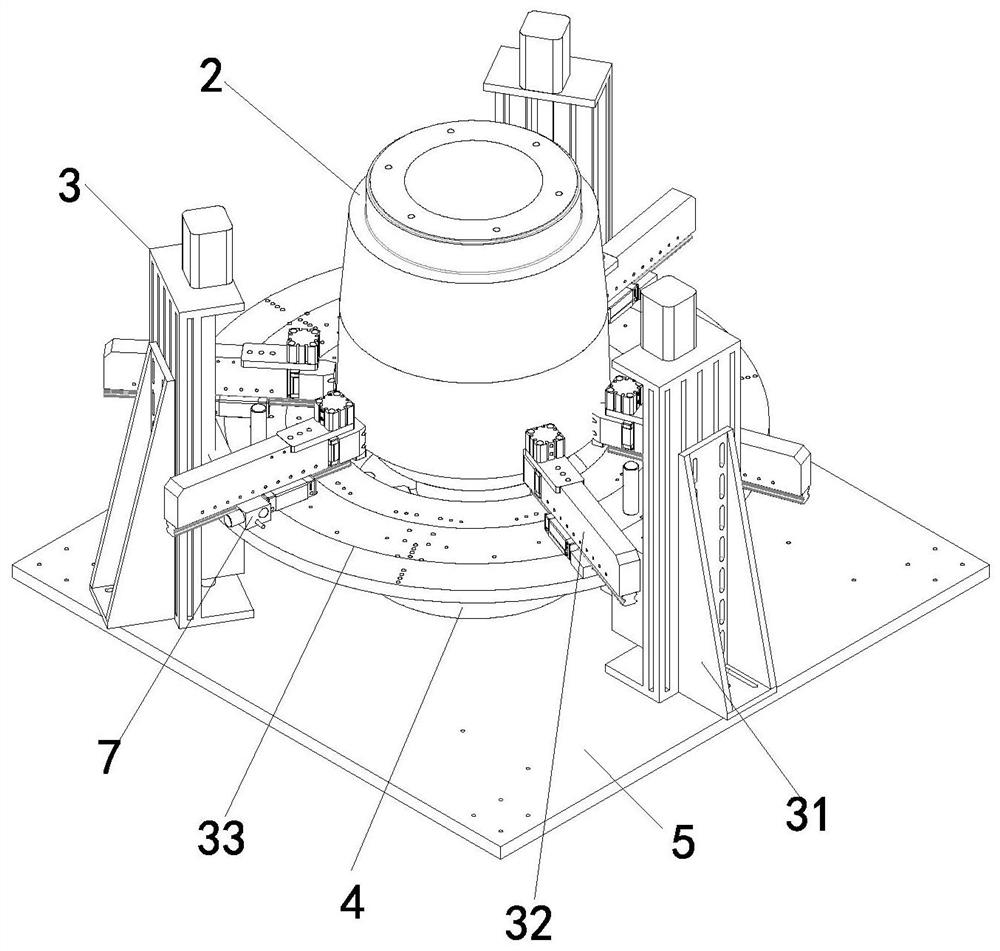

[0034] Specific implementation two: refer to Figure 2 to Figure 8 This embodiment will be described. This embodiment further limits the specific embodiment 1. In this embodiment, the demolding device includes a sealing cover 1, a separation mechanism 3, a clamping mechanism 4, a base 5 and a liquid nitrogen circulation device 6; The separation mechanism 3, the clamping mechanism 4 and the sealing cover 1 are all installed on the base 5, the mandrel mold 2 is installed on the clamping mechanism 4, and the separation mechanism 3 is used to separate the mirror shell on the mandrel mold 2, The sealing cover 1 covers the mandrel mold 2, the separation mechanism 3 and the clamping mechanism 4 so that the three are in a sealed environment, and the liquid nitrogen circulation device 6 injects liquid nitrogen into the mandrel mold 2 and into the sealing cover 1. Inject nitrogen gas for the cold shrinkage of the mandrel mold 2 to facilitate the detachment of the mirror shell.

[0035]...

specific Embodiment approach 3

[0056] Specific implementation mode three: refer to figure 1 This embodiment is described. This embodiment further limits the specific embodiment 2. In this embodiment, implementing the S1 debugging and demolding device includes the following steps:

[0057] S11. Ultrasonic cleaning lifting piece, lifting piece tooling, liquid nitrogen inlet adapter 43, sealing cap, stainless steel tweezers;

[0058] S12. Check whether the components of the demolding device are installed properly:

[0059] Specifically: mainly include the pneumatic chuck 41 of the clamping mechanism 4, the vertical guide mechanism 31 of the separation mechanism 3, the long slide rail pair 324, the guide rod 313, the copying claw 32, etc. are installed on the corresponding position of the copying disc 33; The thickness of the mirror shell is different correspondingly to adjust the size of the "step" in front of the copy claw 32;

[0060] S13. Place the cleaned mandrel mold 2 with the mirror shell on the anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com