Epitaxial reaction chamber recovery method, epitaxial growth device and epitaxial wafer

A technology of a reaction chamber and a recovery method, applied in the recovery of an epitaxial reaction chamber, epitaxial wafers, and epitaxial growth devices, can solve the problems of reduced productivity of epitaxial wafers, low MCLT value of epitaxial wafers, which cannot meet customer specifications, etc. , to achieve the effect of shortening recovery time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

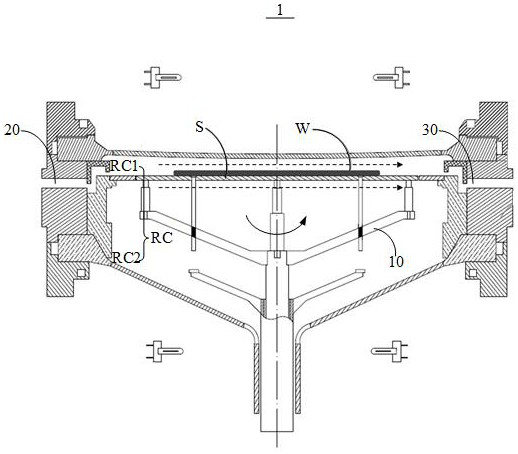

[0022] see figure 1 , which shows a schematic diagram of an existing epitaxial growth device 1 for polishing a wafer W. Such as figure 1 As shown, the epitaxial growth device 1 may include: a base S, a base support frame 10 supporting the base S, and an epitaxial reaction chamber RC, wherein the epitaxial reaction chamber RC is divided into an upper epitaxial reaction chamber RC1 and a lower epitaxial reaction chamber RC1. The reaction chamber RC2, the polished wafer W is placed in the upper epitaxial reaction chamber RC1; the gas inlet 20, the gas inlet 20 is used to transport the reaction gas in the upper epitaxial reaction chamber RC1, for example, with SiHCl 3 For example silicon source gas, hydrogen, with B 2 h 6 or pH 3 Take the dopant gas as an example, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com