Detection method based on reaction process control

A technology of reaction process and detection method, which is applied in the direction of chemical analysis by titration method, can solve the problems of potential detection system instability, large indication error, uncontrollable reaction process, and many by-products of manganese dioxide, etc., to achieve improvement Accuracy and stability, improve the accuracy of temperature measurement, the effect of small amount of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

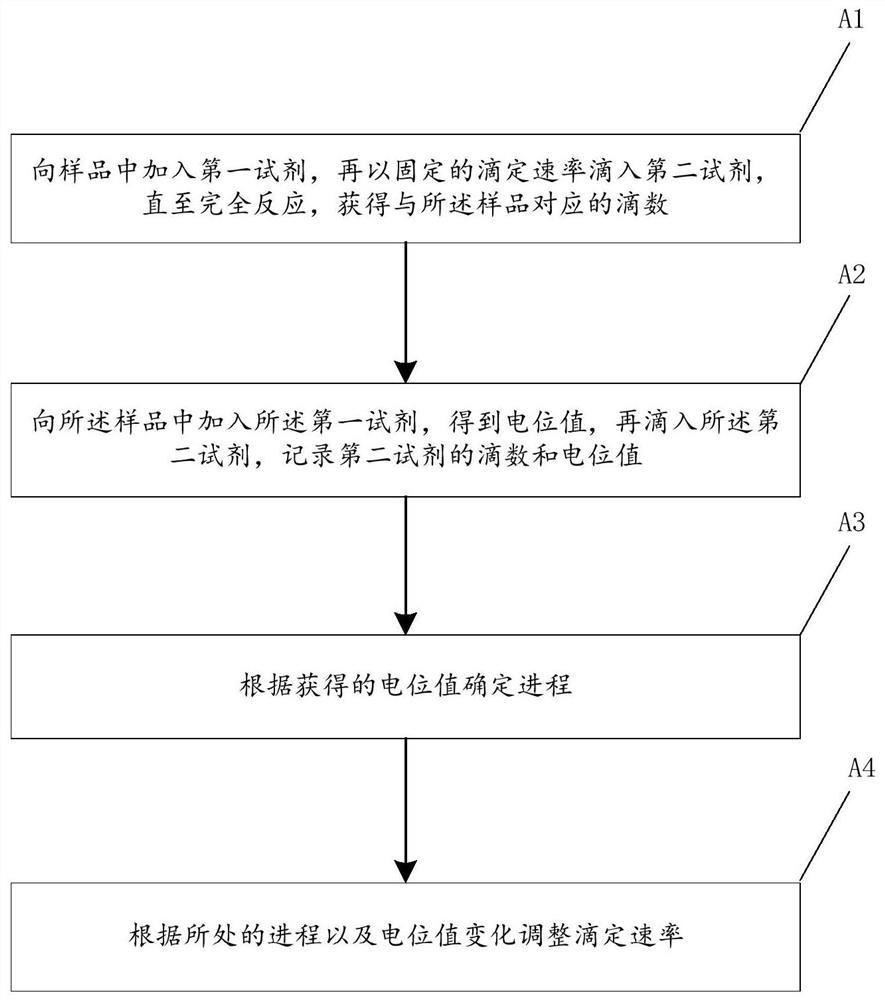

[0029] The detection method based on the reaction process control of the embodiment of the present invention, the detection method based on the reaction process control includes a reaction stage and a titration stage; as figure 1 As shown, the titration phase includes the following steps:

[0030] (A1) Add the first reagent to the sample, then drop the second reagent at a fixed titration rate until the reaction is complete, and obtain the number of drops N corresponding to the sample 0 ;

[0031] (A2) Add the first reagent to the sample to obtain the potential value V 10 , then drop the second reagent, record the number of drops N and the potential value V of the second reagent;

[0032] (A3) Determine the process according to the obtained potential value V;

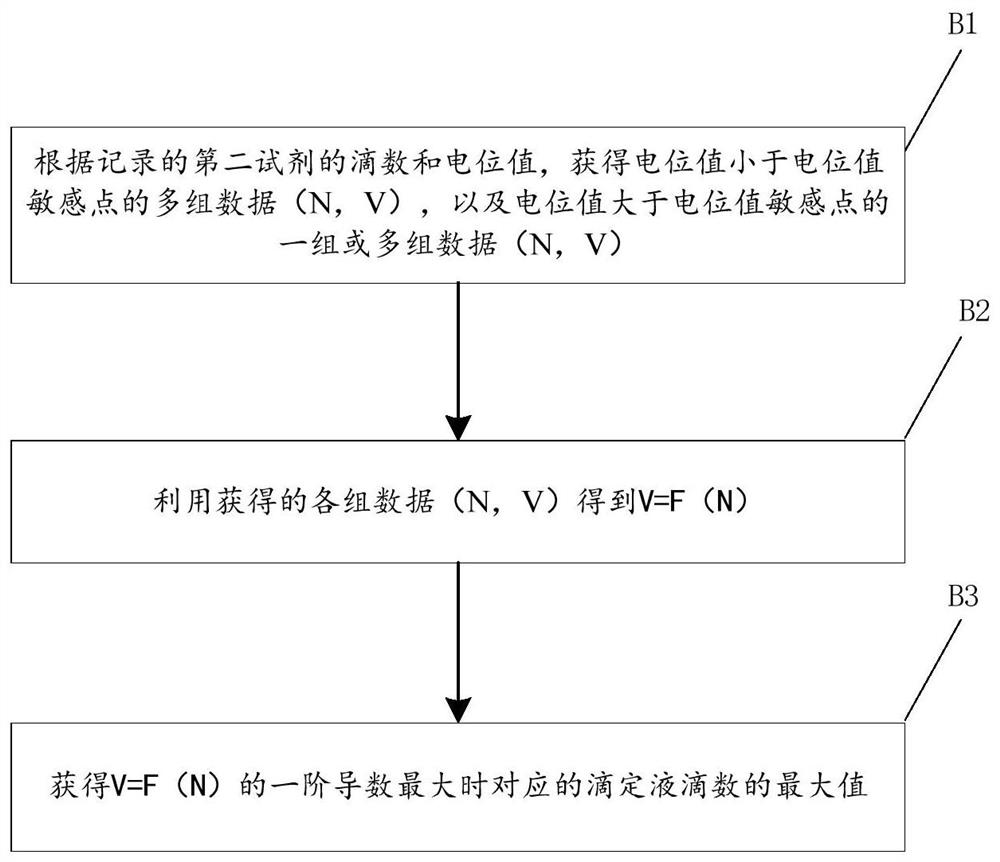

[0033] like and Titration is in the first process, V 0 is the potential value of the first reagent, V t is the potential value of the second reagent; It is the derivative of the potential value V to the number...

Embodiment 2

[0069] An application example of the detection method based on reaction process control in water quality analysis according to Example 1 of the present invention.

[0070] In this application example, the first reagent is sodium oxalate, and the second reagent is potassium permanganate and sulfuric acid, which are gradually dropped into the reaction chamber, and each drop has the same volume;

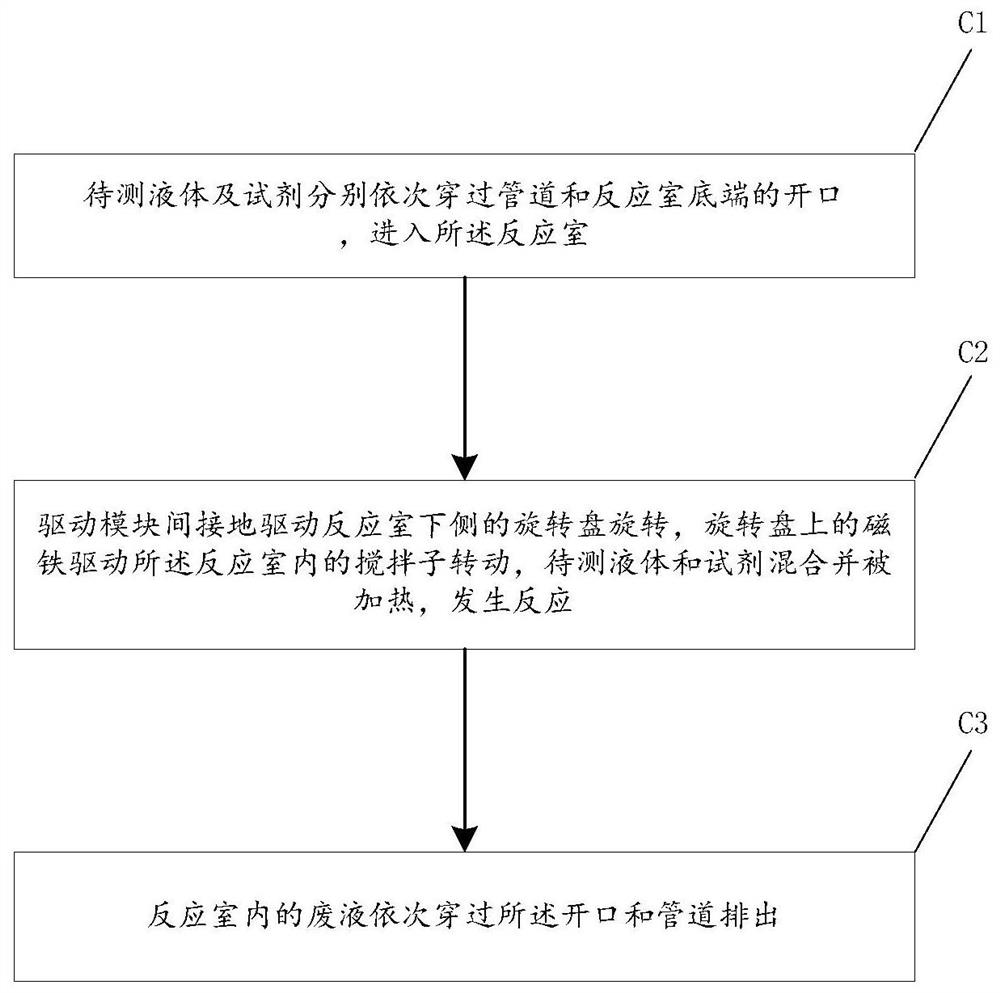

[0071] The center of the bottom end of the reaction chamber has a through hole, and the pipeline communicates with the through hole. The pipeline is used to inject liquid and air (for stirring) into the reaction chamber respectively, and to discharge waste liquid. The pipeline passes through the rotating disk and the support; the rotating disk adopts a gear , arranged on the bracket and at the lower side of the reaction chamber, the pipeline passes through the rotating disk; the magnet is arranged on the rotating disk, and the connecting line between the two magnets passes through the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com