Organic solvent gas concentration detection method

A technology for gas concentration detection and organic solvents, applied in the analysis of gas mixtures, standard gas analyzers, and structural details of gas analyzers, etc., can solve the problems of undetectable, unstable output linearity, short life, etc., to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

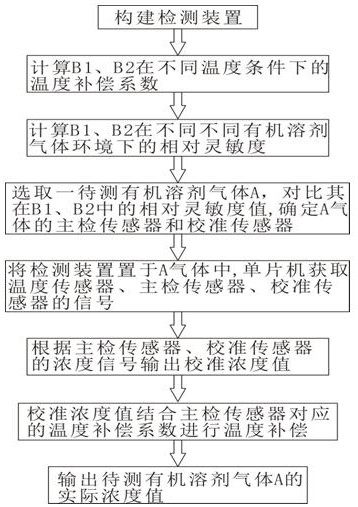

[0060] Embodiment 1: see Figure 1-Figure 3 , a kind of organic solvent gas concentration detection method, comprises the following steps:

[0061] (1) Construct a detection device;

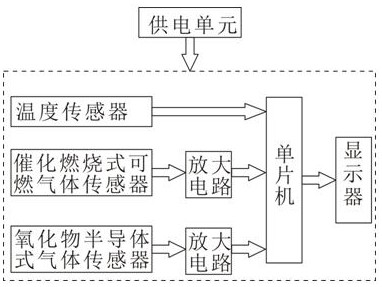

[0062] The detection device includes a single-chip microcomputer, a temperature sensor, a gas concentration sensor unit and a power supply unit, the output of the temperature sensor is connected to the single-chip microcomputer, and the gas concentration sensor unit includes a catalytic combustion combustible gas sensor B1 for detecting the concentration of organic solvent gas and the oxide semiconductor gas sensor B2, both of which are respectively connected to the single-chip microcomputer through an amplifying circuit;

[0063] (2) Calculate the temperature compensation coefficients of B1 and B2 under different temperature conditions;

[0064] (3) Calculate the relative sensitivity of B1 in different organic solvent gas environments, including (31)-(33);

[0065] (31) Take the responsivity ...

Embodiment 2

[0086] Example 2: see Figure 1-Figure 3 , on the basis of Embodiment 1, we further define that it also includes step (6), the single-chip microcomputer is connected to a display, and the calculated actual concentration value is displayed in real time through the display. All the other are identical with embodiment 1.

Embodiment 3

[0087] Embodiment 3: see Figure 1-Figure 3 , on the basis of Example 1 or 2, we limit that B1 and B2 should be zero-point calibrated before use, specifically: put the detection device in an environment of 20°C, and after power-on and aging for 24 hours, then B1 and B2 will work at this time The voltage value is calibrated to its zero point.

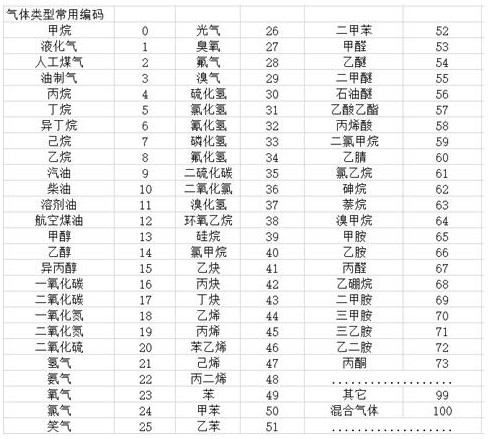

[0088] The zero point calibration is as follows: the single-chip microcomputer has a built-in concentration calculation formula corresponding to B1 and B2 of various organic solvent gases, and when the type of organic solvent gas is known, the single-chip microcomputer calls the corresponding concentration calculation formula and displays its corresponding B1 and B2 initial concentration value.

[0089] The organic solvent gas includes VOC gas, ammonia gas and hydrogen sulfide.

[0090] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com