High-capacity soft-package lithium battery liquid injection method

A soft-pack lithium battery, high-capacity technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of large size, uneven distribution of electrolyte, easy deformation, etc., to improve electrical performance and safety performance, Improve wetting and diffusion efficiency, prevent bursting or bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A liquid injection method for a high-capacity soft-pack lithium battery, comprising the steps of:

[0025] 1. Take the 300Ah soft-pack lithium battery and load it to the weighing station for scanning and weighing;

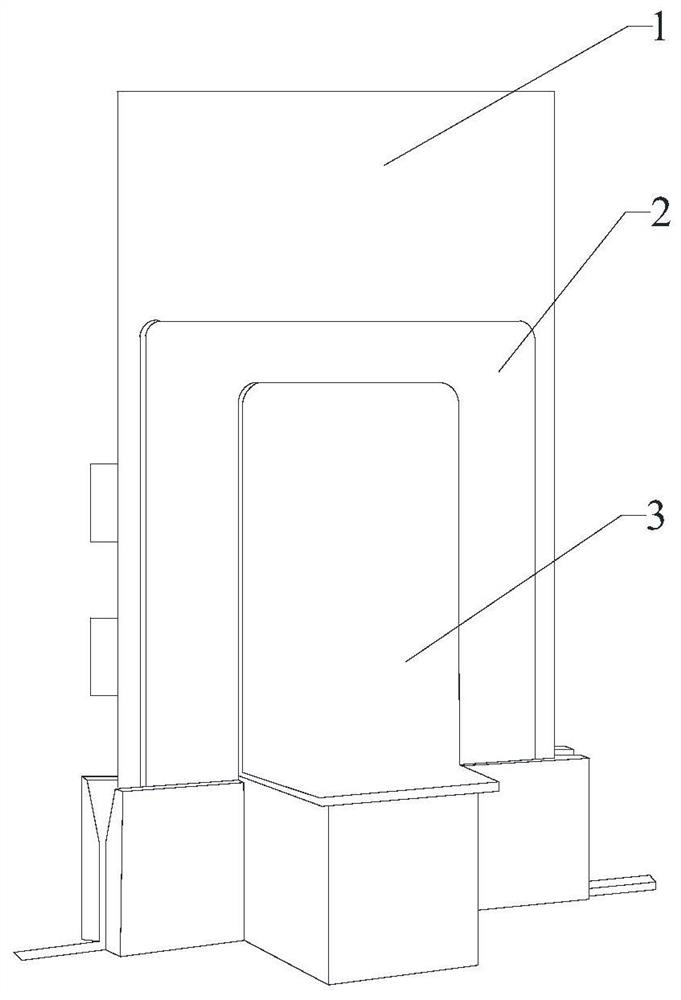

[0026] 2. Please refer to figure 1 , the soft-pack lithium battery is transferred from the scanning code weighing station to the liquid injection station, the first battery air bag 1 of the first battery body 2 of the soft-pack lithium battery faces upward and is placed vertically in the fixture with two sides 3 Liquid injection is carried out in the vertical liquid injection cavity;

[0027] 3. Turn the liquid injection cavity holding the soft-packed lithium battery from the liquid injection station to the vacuum static station, and perform slow vacuuming at -50kPa, -70kPa and -80kPa in sequence (to the vacuum setting within 10 seconds) value), and then carry out air bag packaging under -80kPa vacuum;

[0028] In this embodiment, an additional pressure-h...

Embodiment 2

[0032] A liquid injection method for a high-capacity soft-pack lithium battery, comprising the steps of:

[0033] 1. Take the 300Ah soft-pack lithium battery and load it to the weighing station for scanning and weighing;

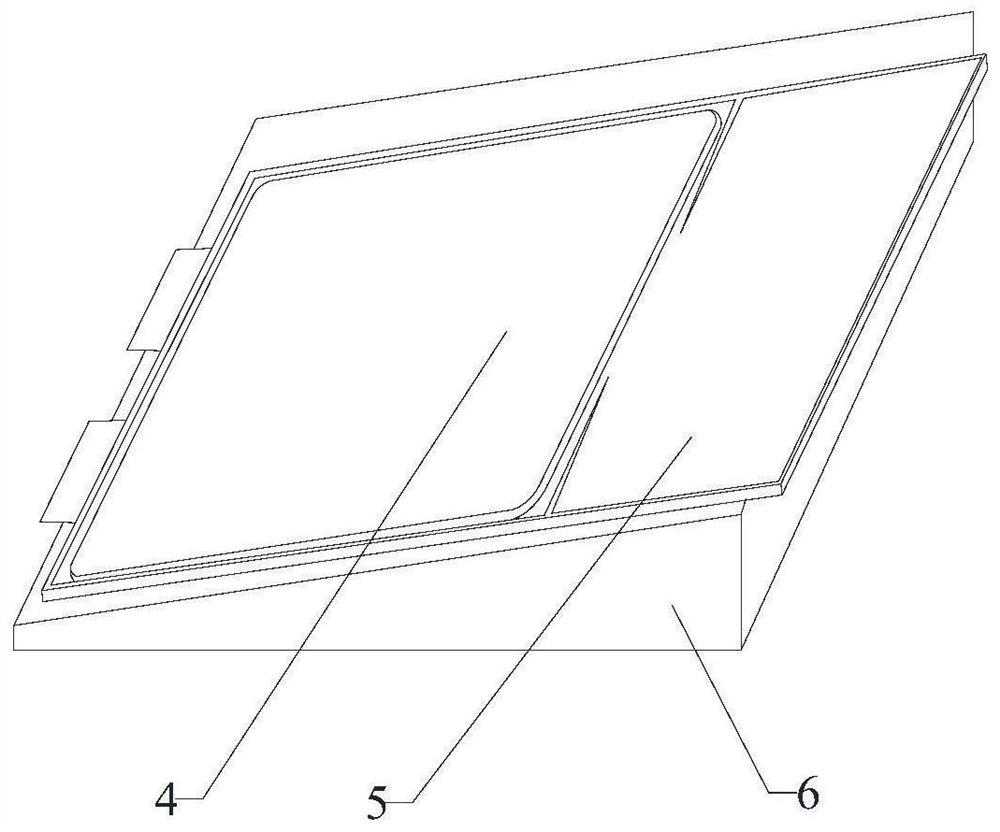

[0034] 2. Please refer to figure 2 , the soft-packed lithium battery is transferred from the code scanning and weighing station to the liquid injection station, and the second battery air bag opening 5 of the second battery body 4 of the soft-packed lithium battery is inclined upward at an angle of 15 degrees to the horizontal line Angle, placed on the inclined liquid injection cavity 6, and inject liquid; the inclined liquid injection cavity is provided with an inclined fixture with the same inclination angle as the liquid injection cavity;

[0035] 3. Turn the inclined liquid injection chamber 6 inclined at an angle of 15 degrees from the liquid injection station to the vacuum static station, and carry out slow vacuuming at -50kPa, -70kPa and -80kPa in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com