Self-centering digitally-controlled main pipe and branch pipe assembling device and using method

A self-centering and self-centering chuck technology, applied in the field of pipeline processing, can solve the problems of inconvenient radial and axial movement, poor support effect of pipe fittings, difficulty in meeting the required precision, etc., to achieve convenient and accurate docking, Simplify equipment and process flow, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

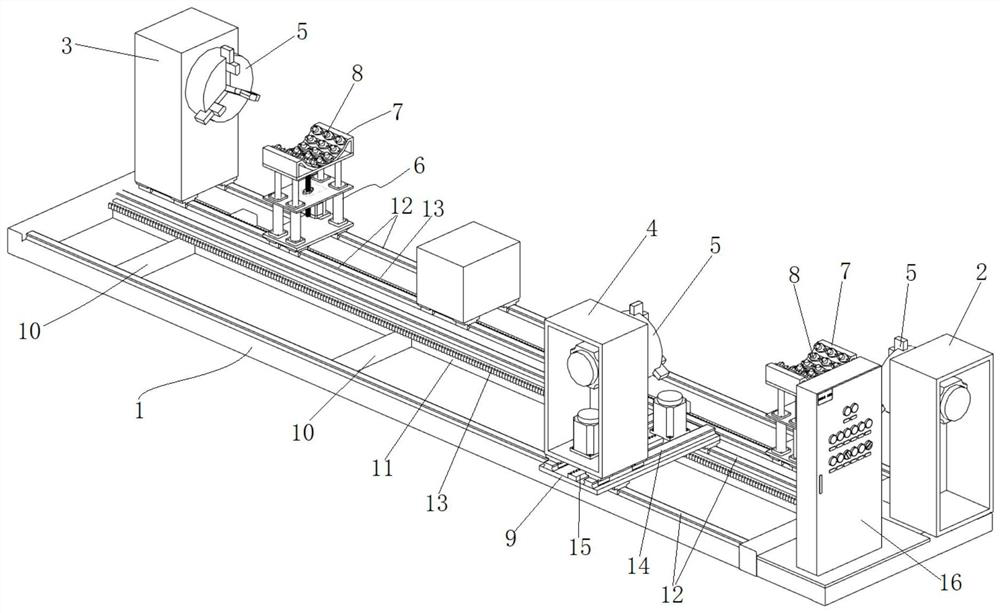

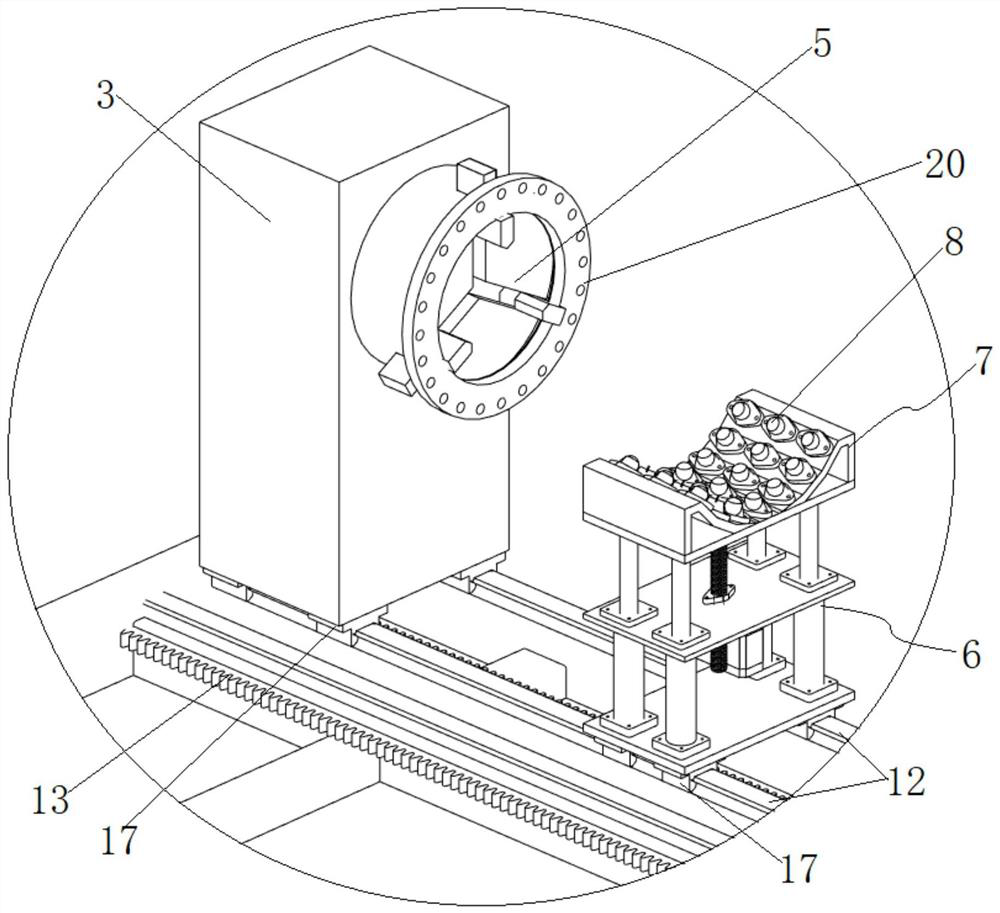

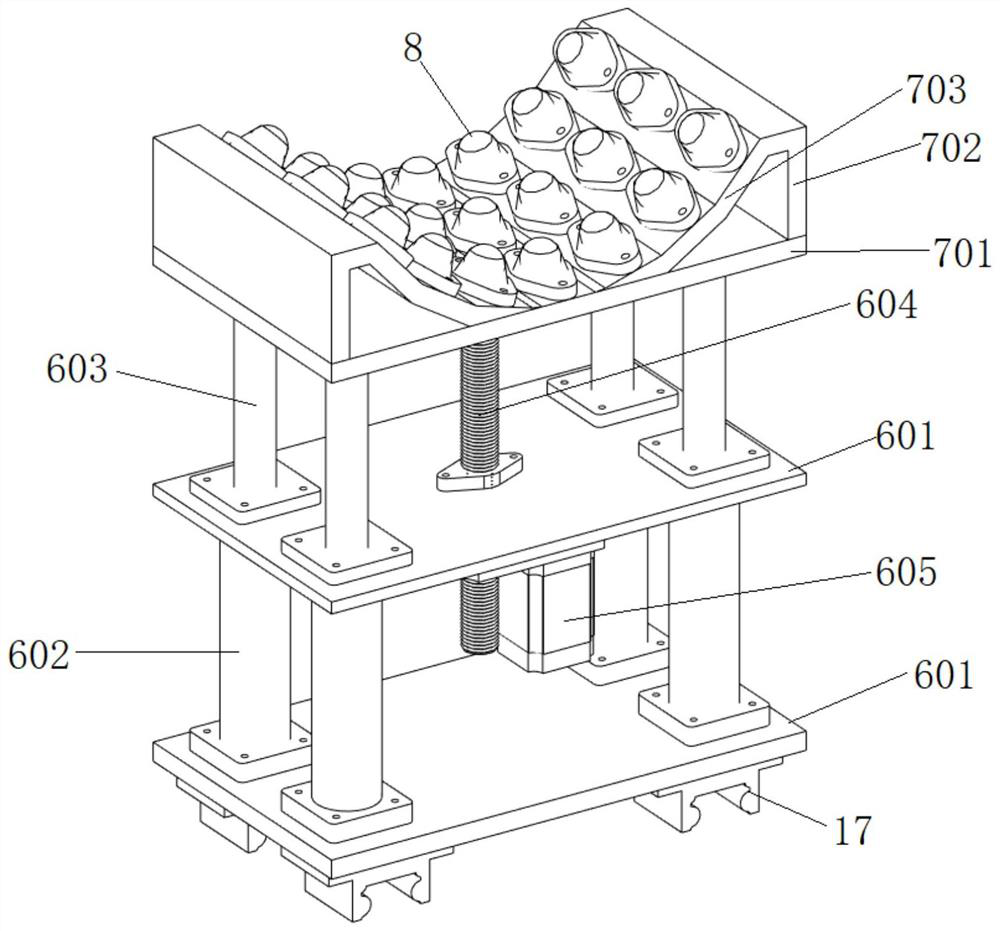

[0045] Such as figure 1 and figure 2 As shown, a self-centering digitally controlled trunk and branch pipe assembly device includes a bottom frame 1. The bottom frame 1 is provided with several slide rail assemblies along the length direction, and one end of the bottom frame 1 is provided with a main pipe for fixed displacement. Machine 2, the other end is provided with a supervisory mobile positioner 3, said supervisory mobile positioner 3 is set opposite to said supervisory fixed positioner 2 and can move to said supervisory fixed positioner 2 along said slide rail assembly The direction of moving, the main tube fixed positioner 2 and the main tube mobile positioner 3 are respectively equipped with electric self-centering chucks 5 at the same height; the main tube fixed positioner 2 and the main tube mobile positioner There are also a number of movable lifting support assemblies 6 between the position machines 3. The support assemblies 6 are provided with V-shaped supports...

Embodiment 2

[0065] This embodiment provides a method for using a self-centering digitally controlled dry-branch pair device, combining Figure 4 and Figure 5 As shown, the method of use includes the following steps:

[0066] (1) Install the main pipe flange 20 on the electric self-centering chuck 5 of the main pipe fixed positioner 2 and the main main mobile positioner 3 respectively, and install the branch pipe method on the branch pipe mobile positioner 4 Lan 21 is ready for use;

[0067] When the main pipe flange 20 or the branch pipe flange 21 is clamped, the flange holes on the flange are arranged symmetrically and evenly, and the claws do not penetrate the flange holes evenly, so that all flange holes are exposed and symmetrical , which is conducive to maintaining the accuracy of docking;

[0068] (2) adjust the support assembly 6 according to the pipe diameter of the main pipe 18 to be assembled, and stop lifting after the universal ball head 8 on the support assembly 6 reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com