Oil displacement agent for supercritical carbon dioxide displacement and its preparation method and application

A technology of carbon dioxide and oil-displacing agent, which is applied in chemical instruments and methods, bulk chemical production, and drilling compositions, etc., can solve the problems of narrowing of the scope of exposure, small peeling effect of crude oil, and inability of crude oil to be recovered. The effect of increasing sweep efficiency, reducing gas channeling, and enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

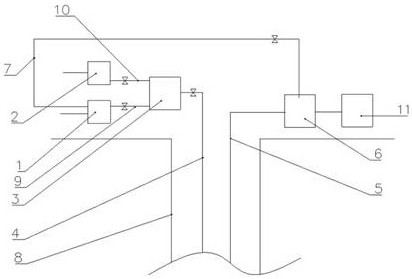

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Oil Displacing Agent 1#

[0041] (1) Under nitrogen protection, 40.0g of ethylene oxide and 140.0g of dipropylamine were added to 180.0g of toluene, and reacted at 75°C for 4 hours to obtain the first intermediate;

[0042] (2) Add 150.0g of the first intermediate and 100.0g of 4-pentenoic acid to 250.0g of xylene, then add 10.0g of concentrated sulfuric acid with a mass concentration of 98%, and react at 120°C for 4 hours to obtain the second intermediate body;

[0043] (3) Under nitrogen protection, add 270.0g of 5-phenyl-1-pentanol to 290.0g of ethylene glycol dimethyl ether, and add 120.0g of 50% sodium hydroxide solution at 70°C, Then 6-chloro-1-hexene was added dropwise, and a total of 120.0 g was added dropwise. After the dropwise addition was completed, the temperature was raised to 80° C. and reacted for 24 hours to obtain the third intermediate;

[0044] (4) Under nitrogen protection, add 240.0g of the second intermediate and 350.0g of the third in...

Embodiment 2

[0045] Embodiment 2 oil displacement agent 2#

[0046] The difference between Example 2 and Example 1 is that in step (1), under the protection of nitrogen, 40.0 g of ethylene oxide and 140.0 g of dibutylamine were added to 180.0 g of toluene, and reacted at 75 ° C for 4 hours , to obtain the first intermediate; the rest of the steps are the same as in Example 1 to obtain oil displacing agent 2#.

Embodiment 3

[0047] Example 3 Oil Displacing Agent 3#

[0048] The difference between Example 3 and Example 1 is that in step (2), 150.0g of the first intermediate and 100.0g of 4-phenyl-4-pentenoic acid were added to 250.0g of xylene, and then 10.0g of Concentrated sulfuric acid with a mass concentration of 98% was reacted at 120°C for 4 hours to obtain the second intermediate; the rest of the steps were the same as in Example 1 to obtain oil displacement agent 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com