Regenerated lubricating oil and treatment process thereof

A treatment process, a technology for lubricating oil, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of a large number of acid residues and waste clay residues, unfavorable environmental protection, difficult treatment, etc., to improve the antioxidant performance and meet the environmental protection requirements. , the effect of improving antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A treatment process for regenerated lubricating oil, comprising the following steps:

[0042] S1. Filtration: Put the waste lubricating oil into the filter for coarse filtration, and filter out the large particles of mechanical impurities in the waste lubricating oil;

[0043] S2. Settling: Pass the waste lubricating oil after coarse filtration into the heater to raise the temperature of the waste lubricating oil to 60°C. The clear water, large particles of impurities and flocculent particles in the waste oil are settled and discharged, and the upper layer The waste lubricating oil enters the next process;

[0044] S3. Refining: After settling, the waste lubricating oil is emulsified with water in oil. The emulsified waste lubricating oil enters the vacuum oil purifier and becomes a very fine oil mist through the nozzle. The relative vacuum degree is -0.08MPa Under certain conditions, different evaporation temperatures of oil and water are used to separate oil and wate...

Embodiment 2

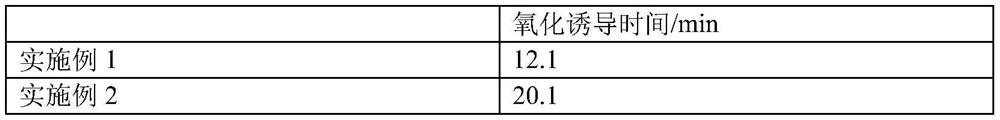

[0061] A treatment process for regenerated lubricating oil, based on Example 1, adding additives to the regenerated lubricating oil obtained in step S4, and adding the additives to the formulated regenerated lubricating oil at a mass ratio of 0.2:100;

[0062] Wherein the additive includes a main antioxidant, and the main antioxidant includes 5 kg of 2,6-di-tert-butyl-4-methoxyphenol.

Embodiment 3

[0064] A treatment process for regenerated lubricating oil, the difference from Example 2 is that the amount of 2,6-di-tert-butyl-4-methoxyphenol is 3kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com