Automatic alternating control system for two motors

A control system and motor technology, applied in motor generator control, AC motor control, control system, etc., can solve problems such as increasing labor intensity of personnel, and achieve the effects of reducing damage and forgetting to switch motors, reducing wear and prolonging maintenance cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

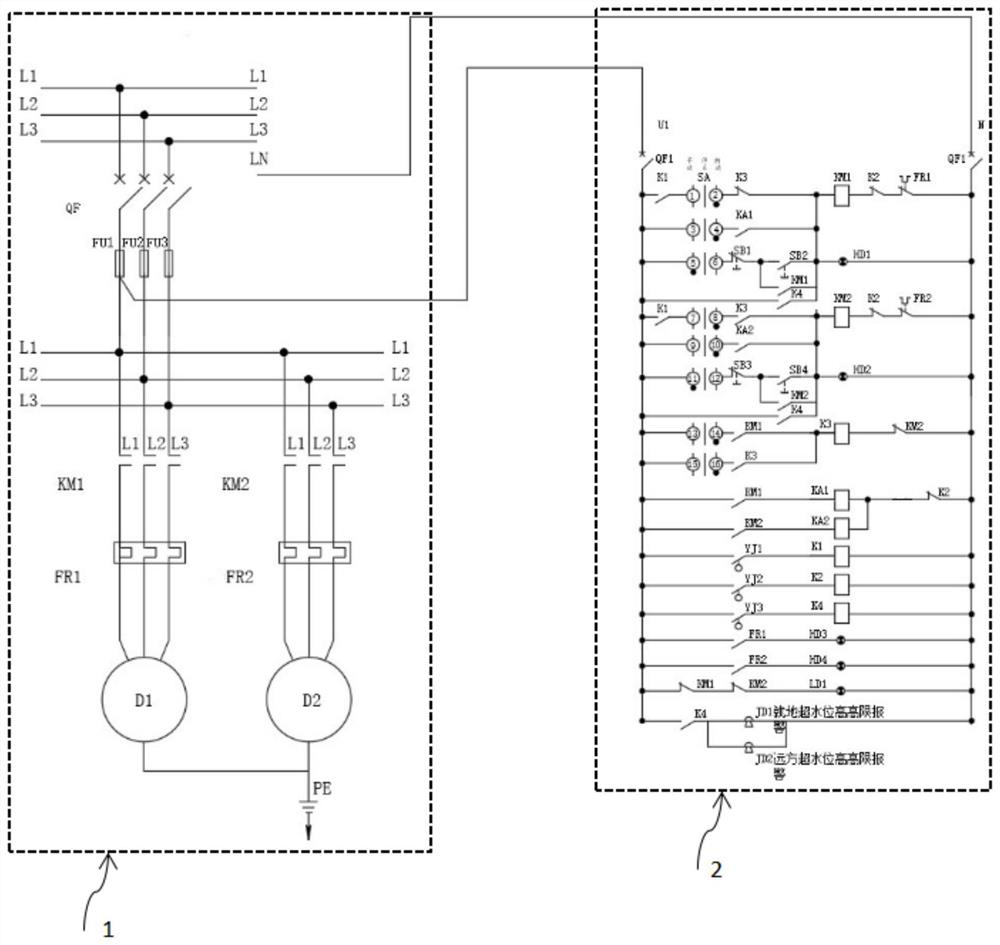

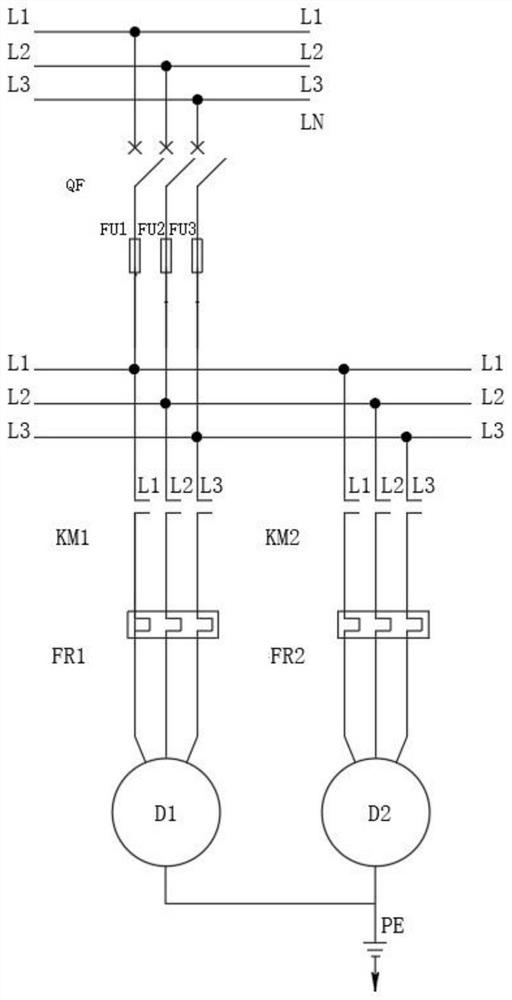

[0043] Please refer to the attached Figure 1-4 , a two-motor automatic rotation control system of the present invention, the system includes a main circuit 1, a control circuit 2, a first check valve 3, a second check valve 4, a water collection well 5, a control box 6, and a #1 water pump 7 and 2# water pump 8; where,

[0044] The main circuit 1 is composed of motor D1, motor D2, thermal relay FR1, thermal relay FR2, AC contactor KM1, AC contactor KM2, fuse FU1, fuse FU2, fuse FU3, main power switch QF; The three live wires L1, L2, and L3 are respectively connected to each terminal. The three live wires L1, L2, and L3 between the motor D1 and the main power switch QF are sequentially connected in series with a thermal relay FR1, an AC contactor KM1, a fuse FU1, and a fuse. FU2, fuse FU3; the three terminals of motor D2 are respectively connected in parallel on the three live wires L1, L2, L3 between fuse FU1, fuse FU2, fuse FU3 and AC contactor KM1, and the three live wires...

Embodiment 2

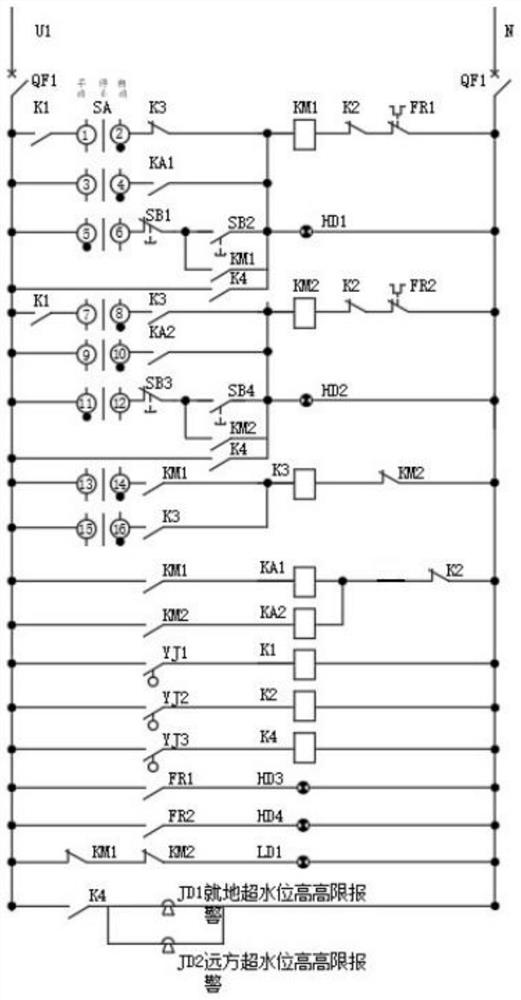

[0068] Based on Example 1, as attached Figure 1-4 , the system works as follows:

[0069] When the two water pumps draining water in the sump 5 are turned off, LD1 lights up, indicating the shutdown state. When it needs to run, close the power switch QF, QF1, the main circuit and the control circuit have been electrified, and turn the manual and automatic transfer switch from the SA "stop" position to the "automatic" position. The conduction of each contact of the transfer switch SA is 1-2, 3-4, 7-8, 9-10, 13-14, 15-16. At this time, the liquid level relay YJ1 that monitors the upper limit of the liquid level detects that the actual water level has reached the upper limit setting value, the liquid level relay YJ1 acts, the relay K1 that starts the 1# water pump 7 is energized, and the normally open contact of the relay K1 receives the current. The 1-2 contacts of the transfer switch SA pass through the normally closed contacts of the rotation relay K3, so that the 1# water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com