Coupler for microwave pyrolysis systems

A coupling and pyrolysis reactor technology, applied in the field of pyrolysis, can solve the problems of stub and stub shell mechanical damage, system loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

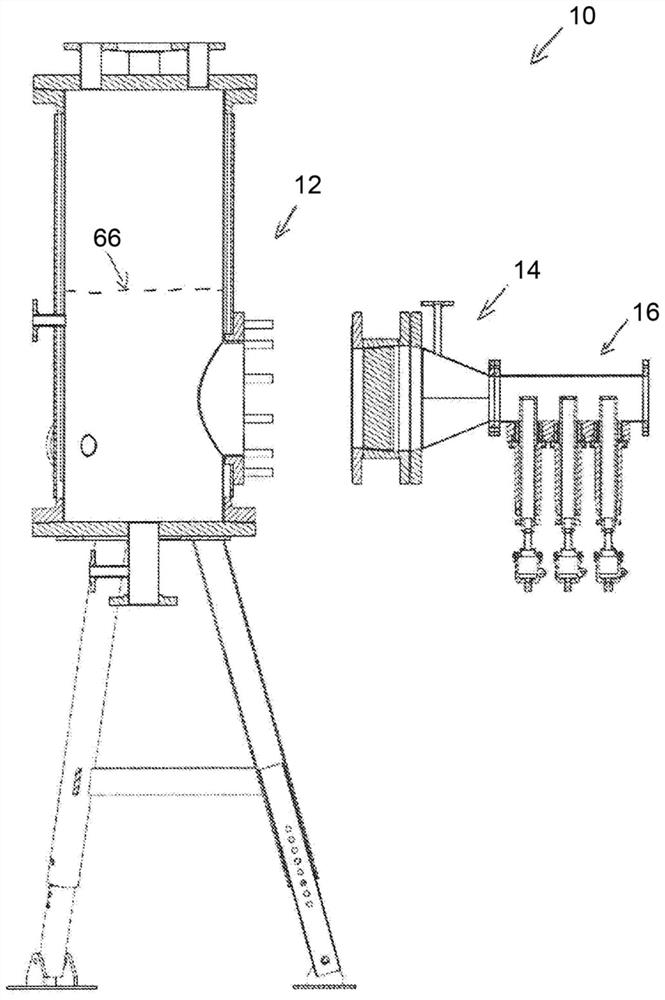

[0058] figure 1 One embodiment of a microwave pyrolysis system 10 is shown that includes a reactor or vessel 12 , a coupling 14 and a tuner 16 . It should be understood that the tuner 16 may be connected to a microwave source or microwave generator (not shown), either directly or via a microwave waveguide. In the illustrated embodiment, a tuner 16 is used to direct the microwaves emitted by the microwave generator to the coupler 14 . The tuner 16 may also be used to adjust the power of the microwave energy delivered to the coupler 16 and thus to the reactor 12 . Coupling 14 is used to propagate microwaves from tuner 16 into reactor 12 . Reactor 12 is configured to receive therein the product to be pyrolyzed, which product is heated by microwave heating.

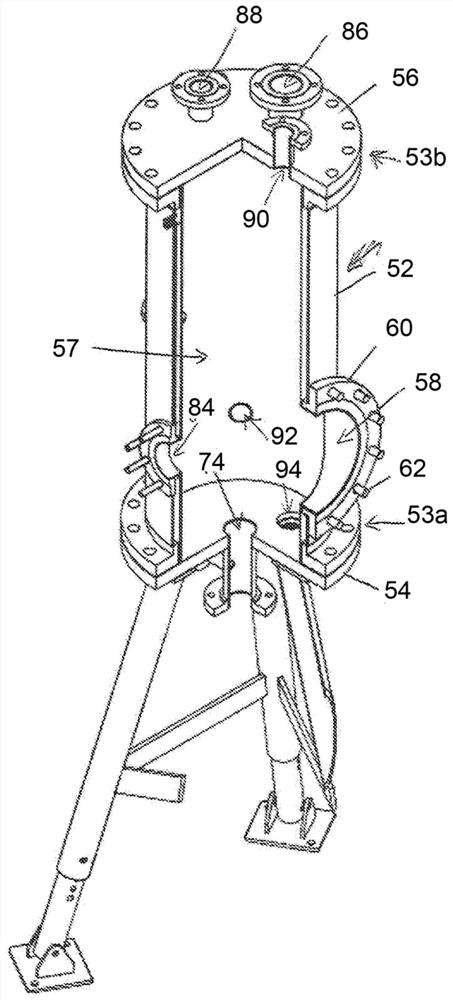

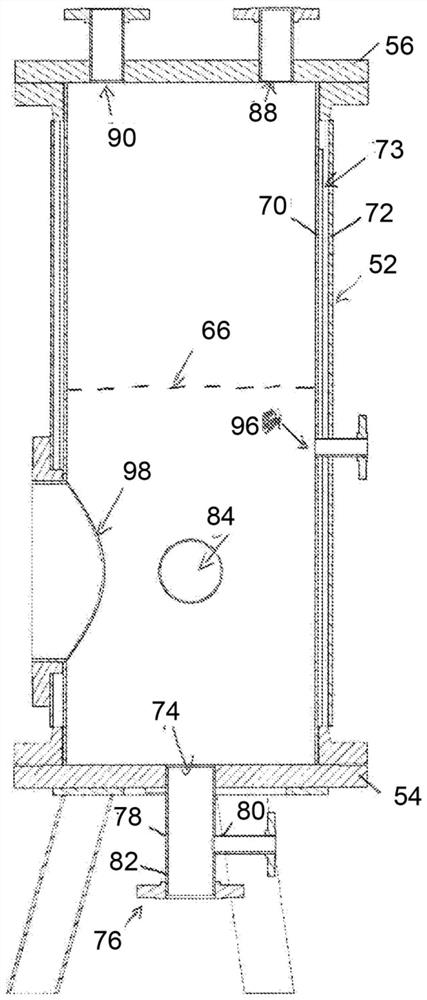

[0059] refer to Figure 2 to Figure 5 , an embodiment of the reactor 12 is shown. Reactor 12 is configured to perform chemical and / or physical reactions therein under the action of microwave energy.

[0060] In the illu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com