Fill level measuring device for determining and monitoring the fill level of a medium in the process space of a container by microwave transit time measurement

A technology of time measurement and microwave propagation, applied in measuring devices, measuring electrical variables, radio wave measuring systems, etc., can solve problems such as leakage, synthetic materials and sealing elastomers are not durable, aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

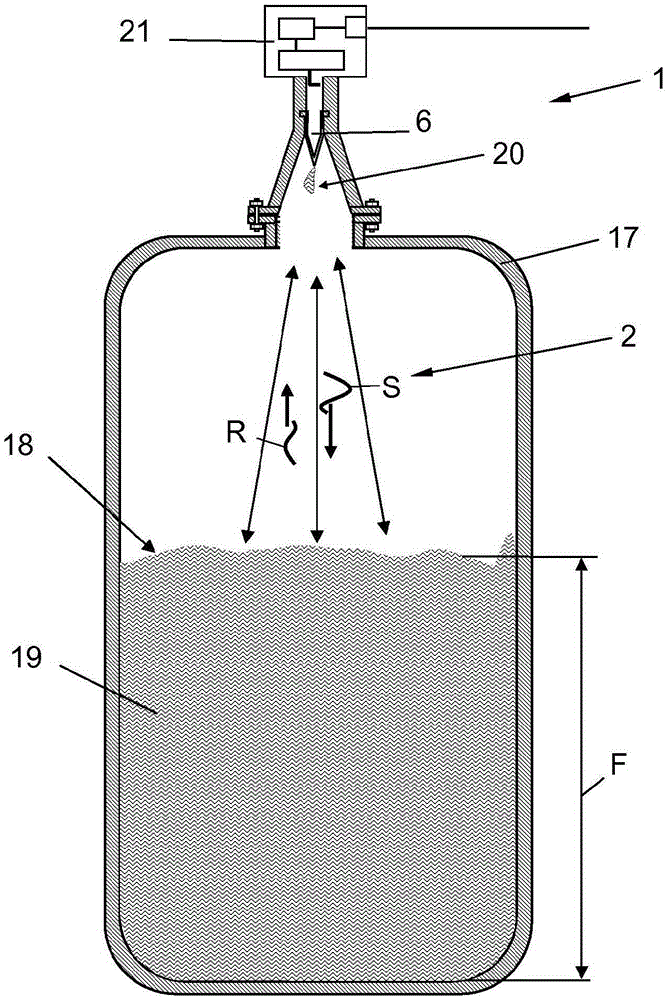

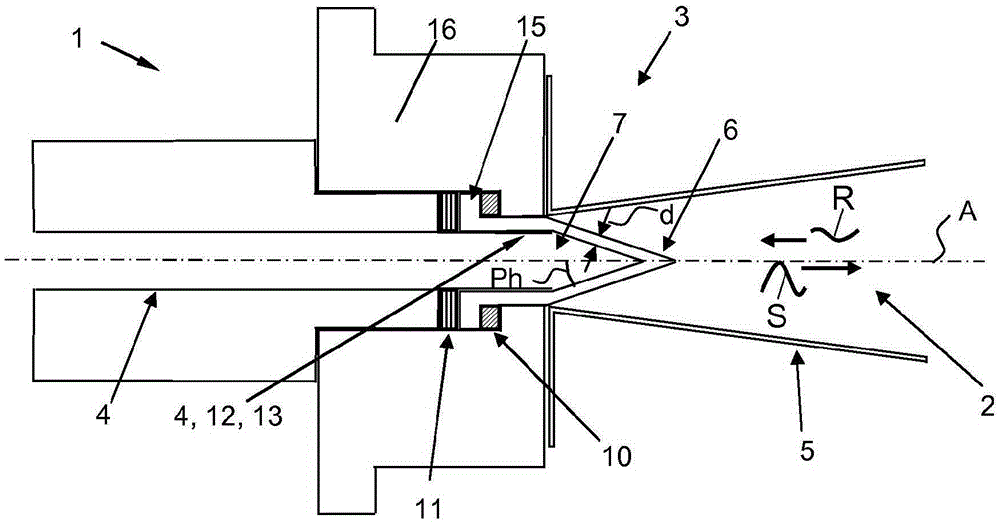

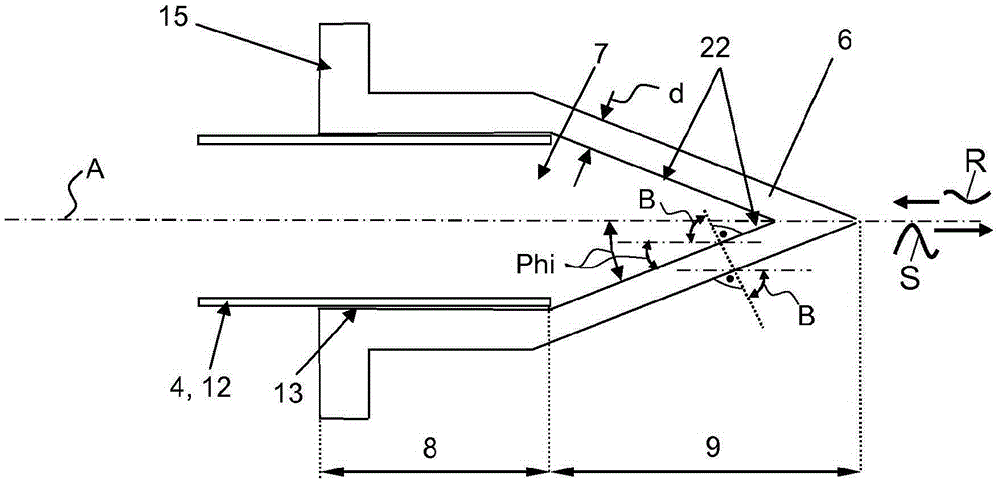

[0031] figure 1 A fill level measuring device 1 is shown which works according to the transit time measurement method for determining the fill level F of the medium 19 . As shown, the filling level measuring device 1 is installed on the nozzle of the container 17 . The shown filling level measuring device 1 consists of a radiating element 5 , in particular a horn antenna, and a measuring transmitter 21 , which radiate microwaves freely into the process space. The measuring transmitter 21 comprises: at least one transmitting / receiving unit, which generates the transmission signal S and receives the reflected signal R of the microwave signal 2; a control / evaluation unit, which is used for signal processing of the microwave signal 2 and for controlling the level measuring device 1 and, a communication unit, which controls the communication via the bus system and the energy supply of the filling level measuring device 1 . In this example of embodiment, for example, the radiation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com