Direct pressure type primary-secondary cylinder of injection molding machine

A technology of direct pressure and master cylinder, which is applied in the field of direct pressure master cylinder of injection molding machine, which can solve the problems that affect the opening and closing of molds of injection molding machines, uneven force distribution, poor clamping effect, etc., and achieve high precision. Difficult to control, reduce material cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

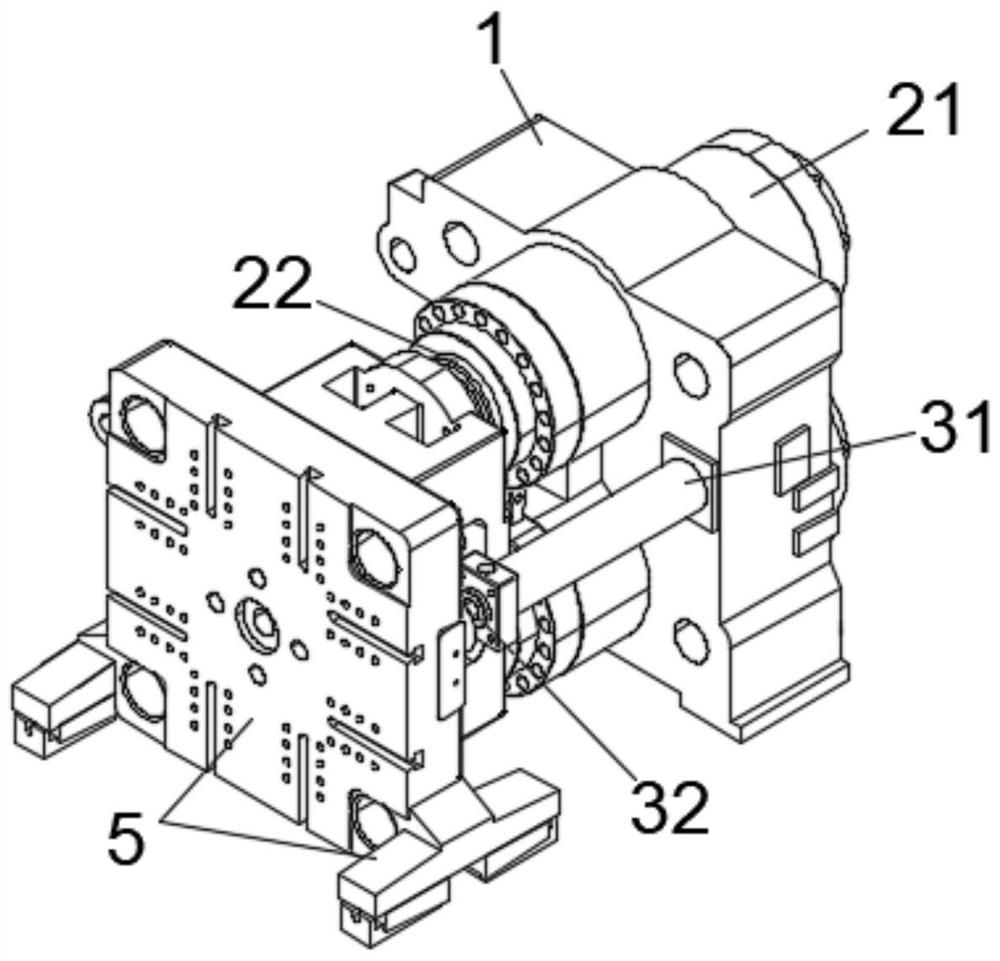

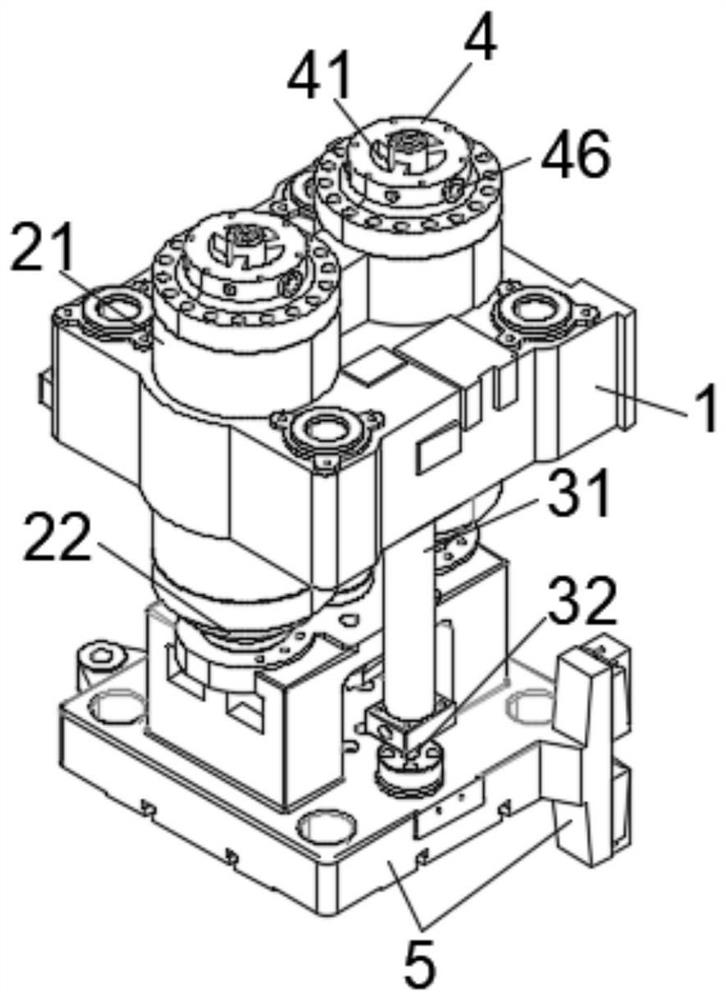

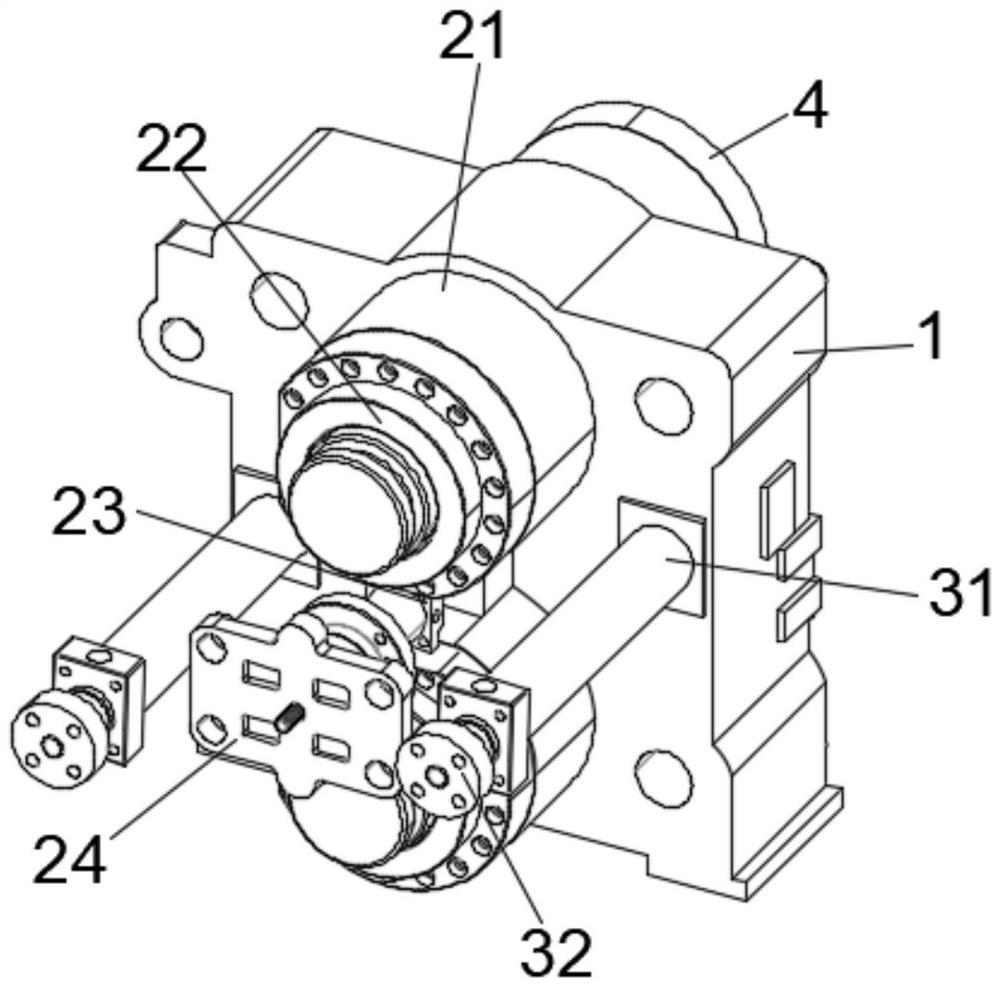

[0025] See Figure 1-6 , The present invention provides a direct pressure type injection molding machine cylinder picture aspect: the template 1 comprises, after the template is provided with a clamping cylinder 21 fitted, and is provided with suction pressurized clamping cylinder assembly 21, suction pressurized oil of the cylinder head assembly comprises a clamping cylinder provided at the tail 4 of 21, the end face of the cylinder head 4 is provided with an oil cap plate, a plurality of fixing holes provided on the cover plate, and is fixed by screws to the oil inlet orifice member 4 is connected to the cylinder head oil , 4 cylinder lid 21 and the clamping cylinder in communication with the oil feed member 41 on the cylinder head oil 4, the oil feed member is provided as a hole into fan-shaped distribution 41, and the oil feed member 41 and equipped with the cooperating movable column 43, column 43 is connected with a closed end surface active plate 44, positioned into the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com