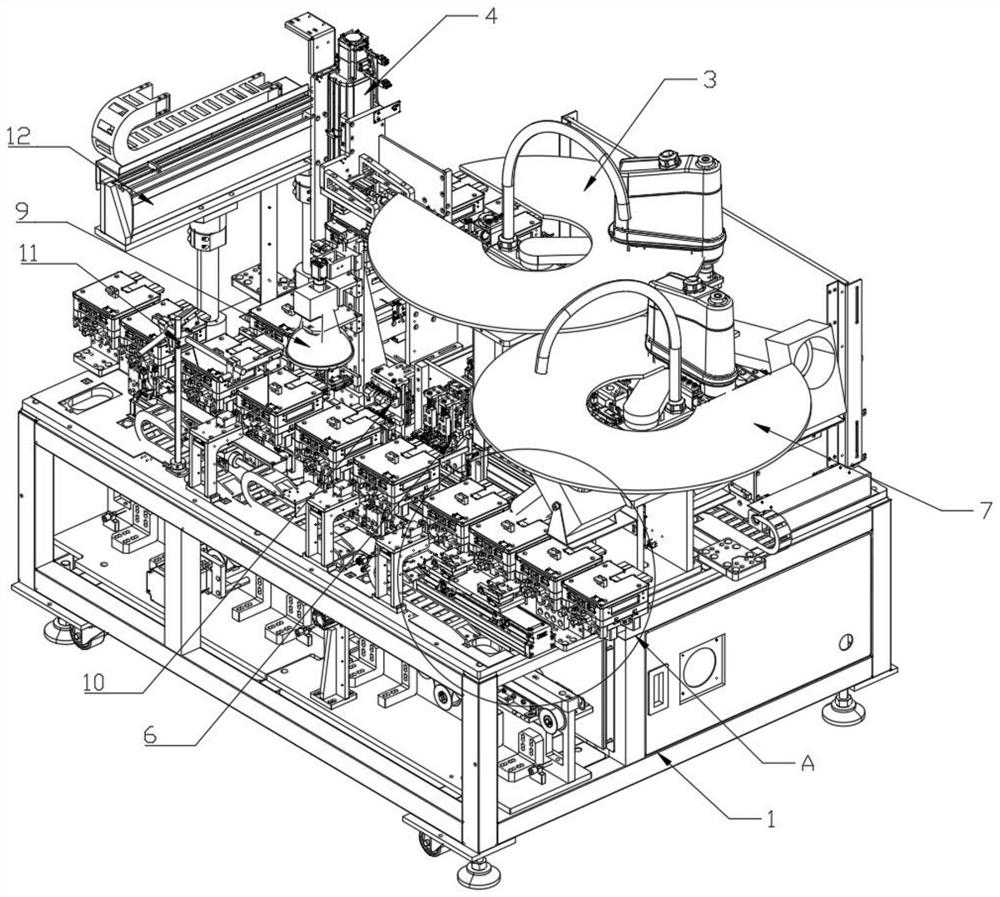

Linear double-station alternate synchronous conveying fine positioning mechanism

A positioning mechanism and double-station technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and low economy, achieve the goal of saving occupied area, small volume, and improving welding production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

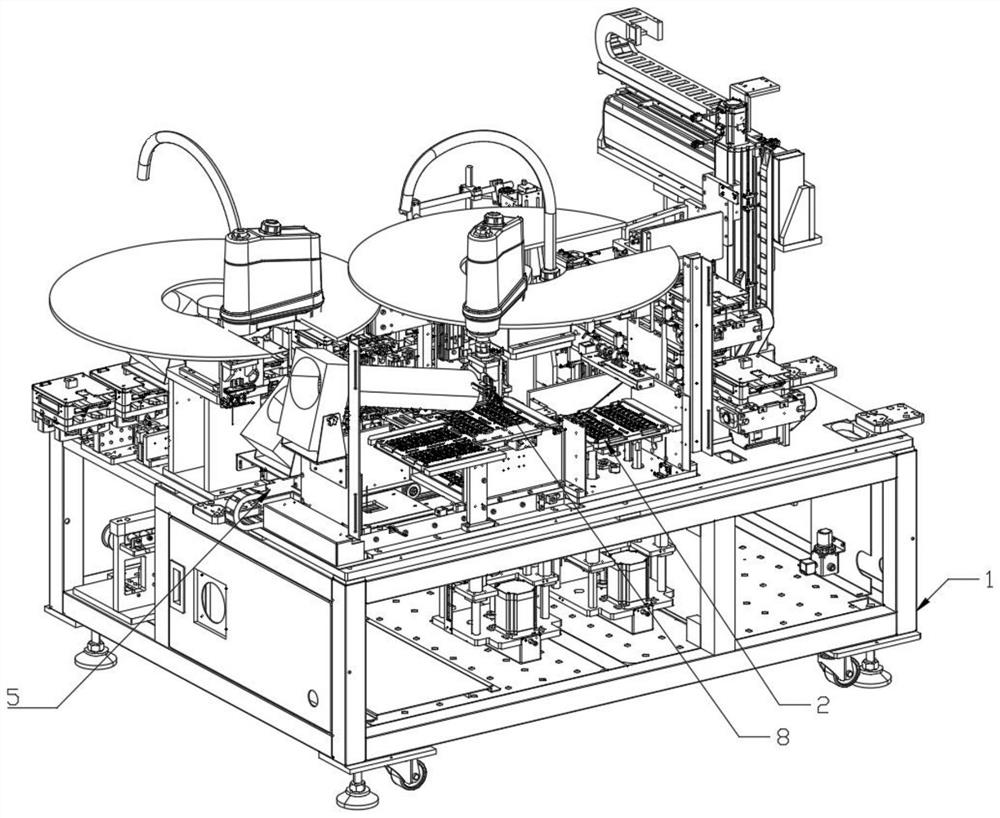

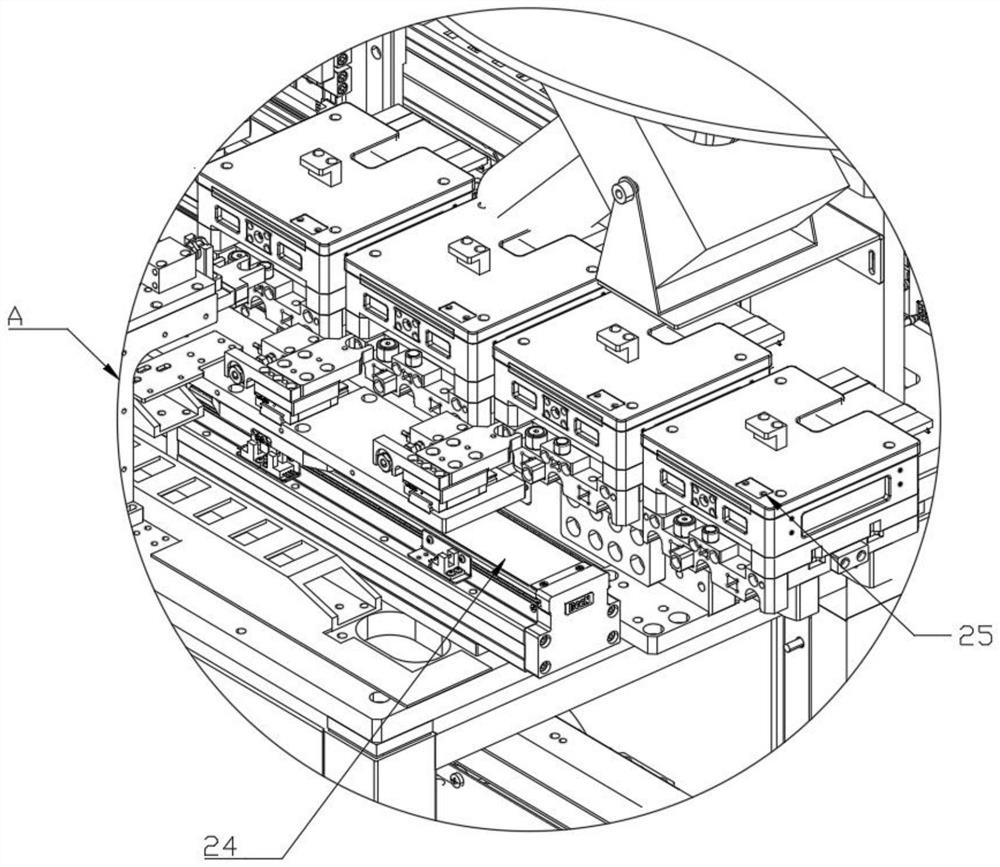

[0019] like Figure 1 - Figure 5 As shown, the linear dual station provided by the present invention alternately synchronously transports the fine positioning mechanism, including the rack 1, and the upper part of the upper part of the lower frame 1 is provided with a PCM silo 2, and the top of the rack 1 is located in PCM The wall of the silo 2 is also provided with a transfer tetraix robot 3, and a handling robot 12 is also provided on the top of the upper part of the rack 1. CCD4, the upper end of the lower end of the lower end of the lower end is also provided with a PCM plate flip positioning mechanism 5; top of the lower frame 1 is also provided with a linear dual station on the side of the PCM board flip positioning mechanism 5. Alternate synchronous transportation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com