Flexible actuator, working method and robot

An actuator and flexible technology, applied in the field of robotics, can solve the problems of complex control algorithm, large mechanical disturbance, complex mechanism, etc., to achieve the effect of solving mechanical disturbance, avoiding mechanical vibration, and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

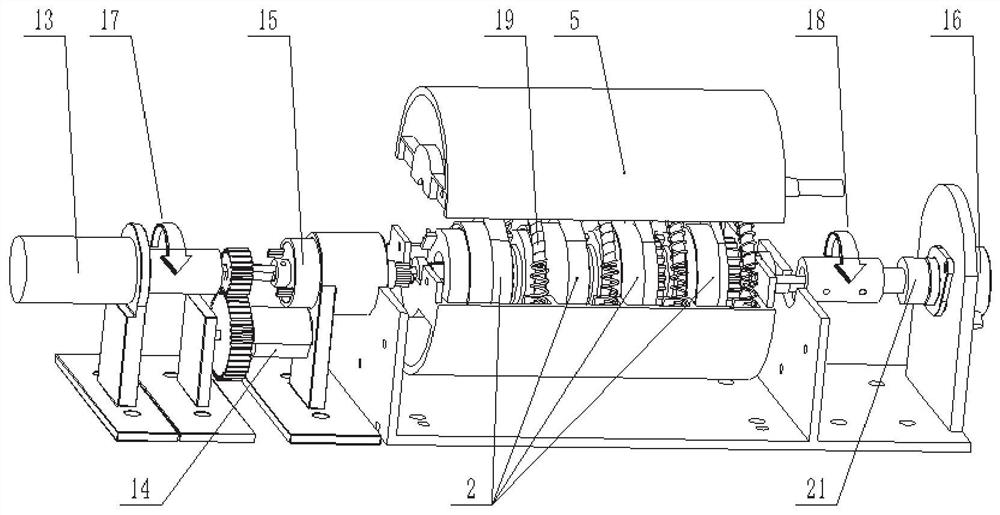

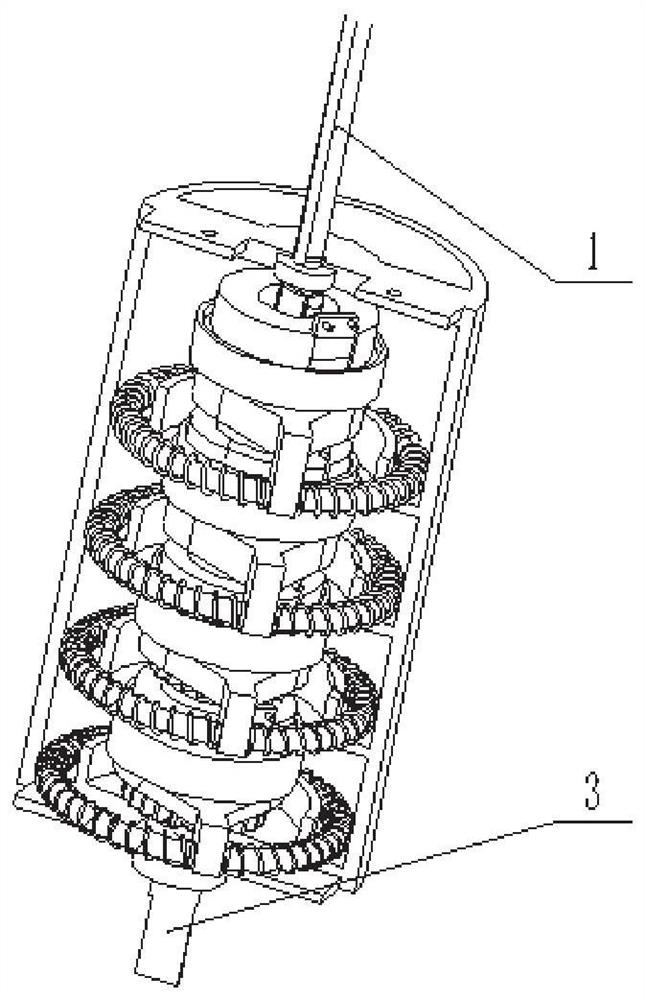

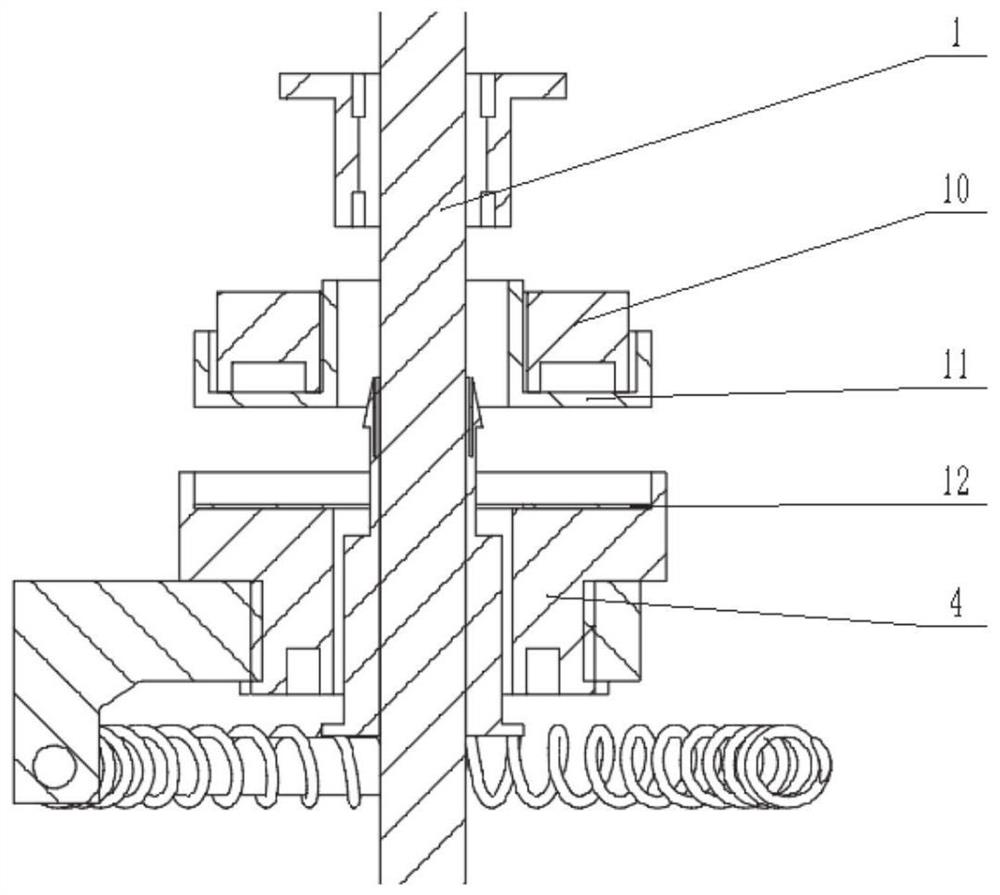

[0063] In a typical embodiment of the present invention, refer to figure 1 , figure 2 and Figure 4 , Figure 5 As shown, a flexible actuator includes a power input shaft 1, and a plurality of electromagnetic clutches 2 are coaxially installed on the power input shaft in series, and a bending elasticity is provided between the thrust plate 20 of each electromagnetic clutch and the transmission frame 6 of the electromagnetic clutch. Part 8, the curved elastic part 8 is installed on the sleeve 9 of the transmission frame and contacts with the baffle plate 7 of the transmission frame, the curved elastic part 8 is connected with the clutch output gear 4 of the electromagnetic clutch 2 through the transmission frame, and the electromagnetic clutch transmission frame 6 and The clutch output gear 4 is fixedly connected and rotates coaxially, forming a power transmission chain from the clutch output gear 4 to the curved elastic member 8 .

[0064] refer to Figure 4 and Figure ...

Embodiment 2

[0077] This embodiment analyzes the theoretical model of the flexible actuator in the first embodiment, and then analyzes the theoretical model of the bending elastic member;

[0078] Dynamic modeling of flexible actuators:

[0079]

[0080]

[0081] θ 2 = θ 1 -q

[0082] where q, θ 1 , θ 2 They are the rotation angle of the power output shaft 18, the rotation angle of the power input shaft 17, and the compression deflection angle 19, M, J are the reflection inertia of the power output shaft and the power input shaft respectively, C, D are the power output shaft and the power output shaft respectively The equivalent damping coefficient of , G(q) is used to compensate the gravitational torque of the PTO shaft, τ d (t) is used to compensate the load torque when the flexible actuator is running, the additional torque generated by friction, internal damping and the uncertain disturbance torque due to the manufacturing precision of the flexible actuator. μ represents th...

Embodiment 3

[0119] The invention also discloses a working method of a flexible actuator, including the following content:

[0120] When the electromagnetic coil 10 is energized, a certain magnetic force is generated to attract the passive friction disc 12 to the active friction disc 11, and the torque of the power input shaft is transmitted to the passive friction disc 12 through the two friction discs, and finally the torque is transmitted from the clutch output gear 4 to the transmission frame 6, and then passed to the outer casing 5 through the thrust plate in contact with the curved elastic member 8;

[0121] When the electromagnetic coil 10 is powered off, the coil of the electromagnetic clutch 2 loses its magnetic force, and the passive friction disc 12 and the active friction disc 11 are separated at the same time. At this time, the power transmission is interrupted, and the electromagnetic coil 10 and the active friction disc 11 will rotate independently with the power input shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com