Micron or nano aerosol particle enrichment device

An aerosol particle enrichment technology, applied in the direction of manufacturing auxiliary devices, additive processing, etc., can solve the problems of micron or nanometer aerosol particle enrichment accuracy and low efficiency, and achieve enhanced Safman lift effect, high-efficiency enrichment collection, effects with a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

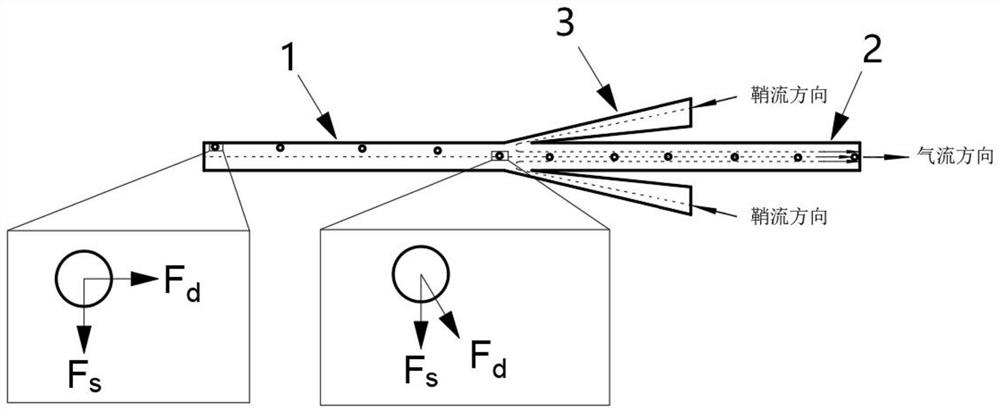

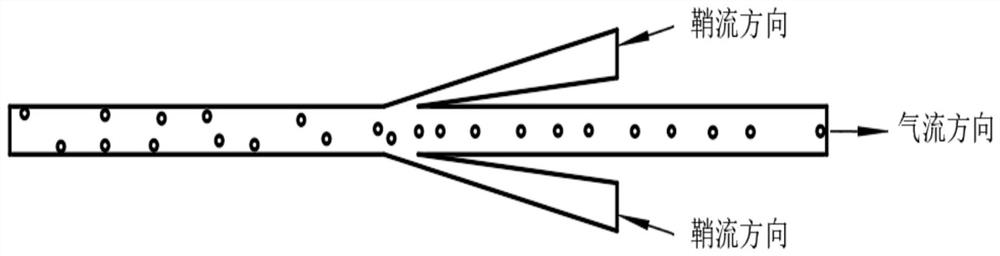

[0048] In this embodiment, two sheath airflow microchannels 3 are provided, and the two sheath airflow microchannels 3 are symmetrically disposed outside the aerosol particles enrichment microchannel 2, which is used to form symmetrical in aerosol particles. The gas stream at the center of the aerosol particles is enriched the center of the microchannel 2 and the speed zero point near the through hole. The aerosol particulate sample microchannel 1 and the aerosol particles enrichment microchannel 2 use small-channel width constant section, the direction of sheath in the sheath gas flow microchannel 3, and the aerosol particles are applied to microchannel 1 and aerosol particles. The airflow direction in the microchannel 2 is inversely, and there is a 2 ° angle, so that the spherner flow has a broader range, and the pressure varies near the outlet of the sheath gas flow microchannel 3 is more gentle, and the particles are hitting the wall. loss.

[0049] Specific verification proce...

Embodiment 2

[0052] The principles of the present embodiment are substantially the same as the above embodiment, and in the present embodiment, the effects of the enrichment of different sheath airflow structures on aerosol particles are verified, for example, forward sheath gave flow and reverse radiospheric stream. See Figure 4 The same sheath gas flow ratio and flow, micrometer or nanogenic sol particles in the positive sheath gas flow and the anti-radiator of the aerosol particles enrichment microchannel 2 exit enriched bandwidth, from Figure 4 It can be seen that the aerosol particles of the reverse sheath gas flow structure are more obvious to the enrichment of aerosol particles, because the reverse radiosphere provides a speed zero point near the spheric inflow, resulting in more As a strong speed gradient, the granules are larger than the Safang power of the center of the channel, and the reverse radopene flow also improves the pressure change in the vicinity of the spheric inflow, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com