Two-gear rotatable hub motor four-wheel-drive trolley

A technology of rotating wheels and trolleys, applied to steering mechanisms, power steering mechanisms, electric steering mechanisms, etc., can solve the problems of only single gear, poor vehicle flexibility, high energy consumption of hub motor transmissions, etc., and achieve shift shock Small, compact, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

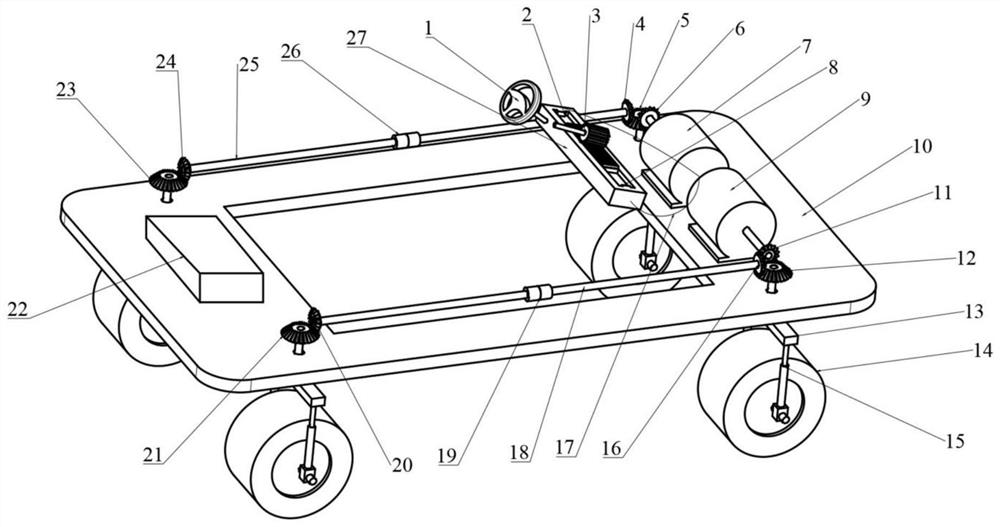

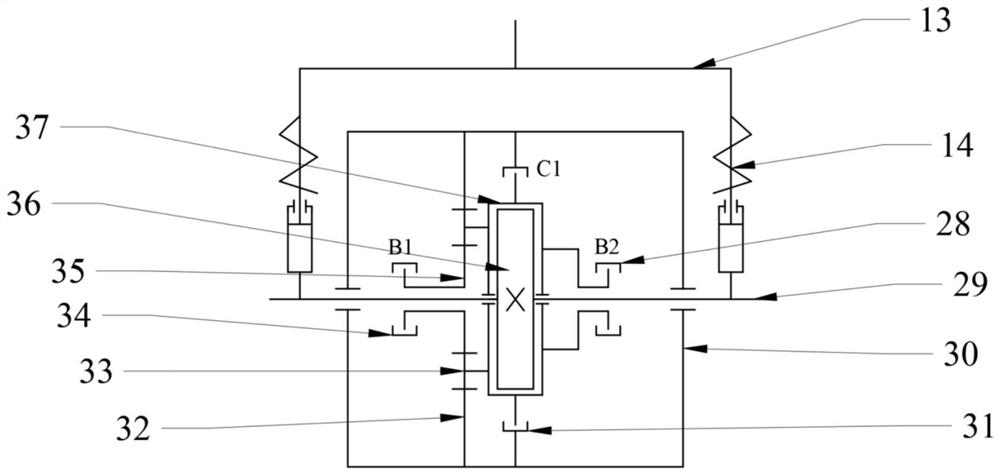

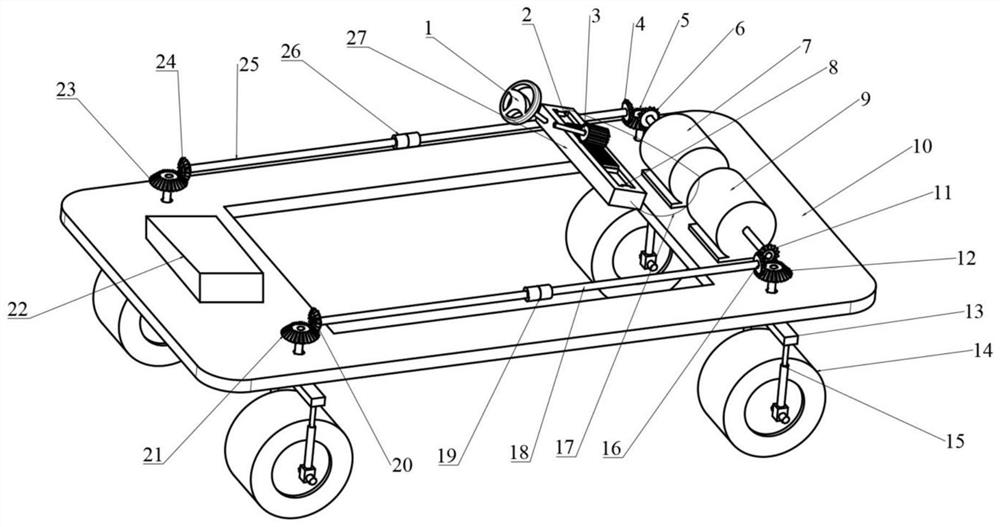

[0021] Such as figure 1 As shown, the present invention relates to a two-speed rotatable in-wheel motor four-wheel drive trolley, which is characterized by a rack-and-pinion steering gear 3, a power steering motor I7, a power steering motor II9, a bevel gear I4, a bevel gear II5, a bevel gear Ⅲ6, bevel gear i11, bevel gear ii12, bevel gear 16, steering bracket 13, hub motor 14, etc.

[0022]The steering wheel 1 is connected with the rack and pinion steering gear 3 through the rotating shaft, the rack of the rack and pinion steering gear 3 is installed in the top groove of the signal processor 27, the rack displacement sensor I2 and the rack displacement sensor II8 are fixed in the signal processing The signal processor 27 is connected to the left and right sides of the groove on the top of the controller 27, and the signal processor 27 is externally connected to the output signal line 17; the power steering motor Ⅰ 7 and the power steering motor Ⅱ 9 are respectively fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com