Preparation method of active manganese dioxide for zinc-manganese dry battery

A technology for active manganese dioxide and zinc-manganese dry batteries, which is applied to dry batteries, manganese oxide/hydroxide, battery electrodes, etc., can solve the problem that the discharge performance of active manganese dioxide cannot meet the requirements of high-quality zinc-manganese dry batteries, the preparation process is complex, and the production Long cycle and other problems, to achieve the effect of favorable migration, simple production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

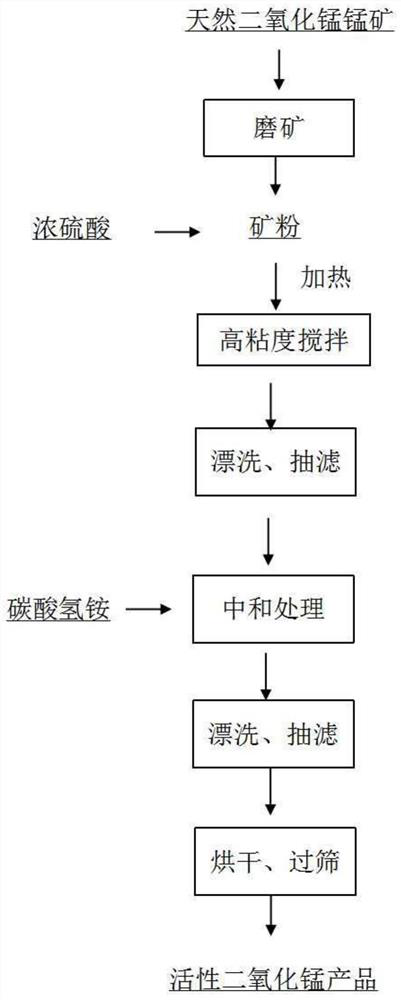

[0036] A kind of preparation method of active manganese dioxide for zinc-manganese dry battery, such as figure 1 shown, including the following steps:

[0037] (1) Grinding the natural manganese dioxide manganese ore into powder, the median diameter (D50) of the powder is 13 μm;

[0038] (2) Add concentrated sulfuric acid in the reaction kettle, the concentration is 98%, and then put in manganese dioxide powder, the mass ratio of concentrated sulfuric acid and manganese dioxide is 1:2, keep warm at 150°C, and fully stir for 8 hours;

[0039] (3) Rinse and filter the stirred mixture several times with hot water at 60° C. (about 4 times), until the pH value of the filtrate reaches about 2.5, and obtain the filtered mixture;

[0040] (4) Add an appropriate amount of ammonium bicarbonate to the mixture after suction filtration, stir for 2 hours, until the pH value reaches about 6.5, and obtain a neutralized mixture;

[0041] (5) Rinse and filter the neutralized mixture several t...

Embodiment 2

[0044] A preparation method of active manganese dioxide for zinc-manganese dry batteries, comprising the following steps:

[0045] (1) Grinding the natural manganese dioxide manganese ore into powder, the median diameter (D50) of the powder is 13 μm;

[0046] (2) Add concentrated sulfuric acid in the reaction kettle, the concentration is 98%, and then drop into manganese dioxide powder, the mass ratio of concentrated sulfuric acid and manganese dioxide is 1:1.5, keep warm at 150°C, and fully stir for 8 hours;

[0047] (3) Rinse and filter the stirred mixture several times with hot water at 60° C. (about 4 times), until the pH value of the filtrate reaches about 2.5, and obtain the filtered mixture;

[0048] (4) Add an appropriate amount of ammonium bicarbonate to the mixture after suction filtration, stir for 2 hours, until the pH value reaches about 6.5, and obtain a neutralized mixture;

[0049] (5) Rinse and filter the neutralized mixture several times with hot water at 60...

Embodiment 3

[0052] A preparation method of active manganese dioxide for zinc-manganese dry batteries, comprising the following steps:

[0053] (1) Grinding the natural manganese dioxide manganese ore into powder, the median diameter (D50) of the powder is 18 μm;

[0054] (2) Add concentrated sulfuric acid in the reaction kettle, the concentration is 98%, and then drop into manganese dioxide powder, the mass ratio of concentrated sulfuric acid and manganese dioxide is 1:1.8, keep warm at 150°C, and fully stir for 8 hours;

[0055] (3) Rinse and filter the stirred mixture several times with hot water at 60° C. (about 4 times), until the pH value of the filtrate reaches about 2.5, and obtain the filtered mixture;

[0056] (4) Add an appropriate amount of ammonium bicarbonate to the mixture after suction filtration, stir for 4 hours, until the pH value reaches about 6.5, and obtain a neutralized mixture;

[0057] (5) Rinse and filter the neutralized mixture several times with hot water at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com