Flame-retardant conveyor belt repair adhesive, and preparation method and use method thereof

A conveyor belt, repair glue technology, applied in the direction of adhesive, adhesive type, rosin adhesive, etc., can solve the problems of complex preparation process, non-flame retardant adhesive, not suitable for conveyor belt bonding, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

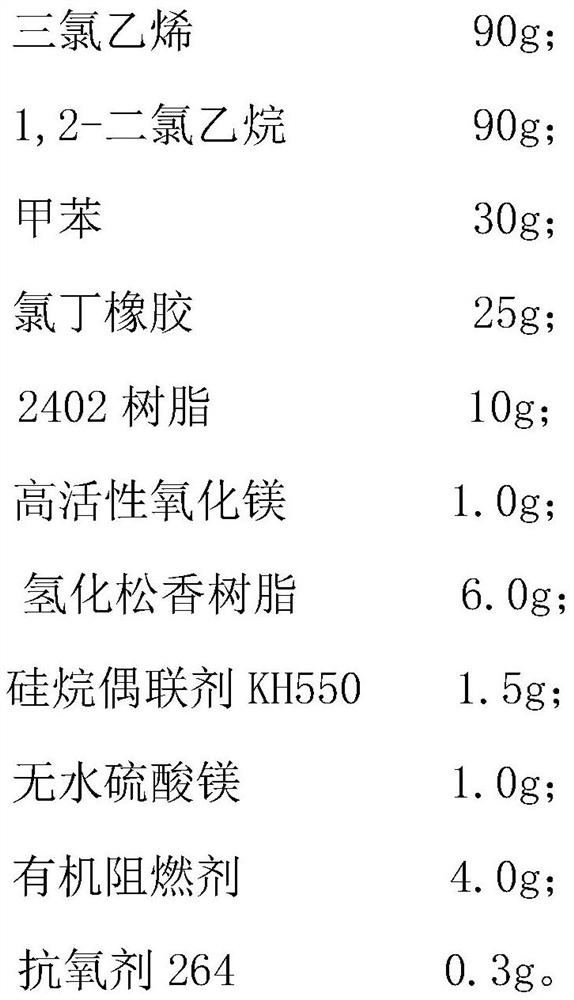

[0039] The composition ratio of a flame retardant conveyor belt repair glue:

[0040]

[0041] The organic flame retardant is an environment-friendly halogen-free nitrogen and phosphorus compound intumescent flame retardant, and its model is Doher-6002A.

Embodiment 2

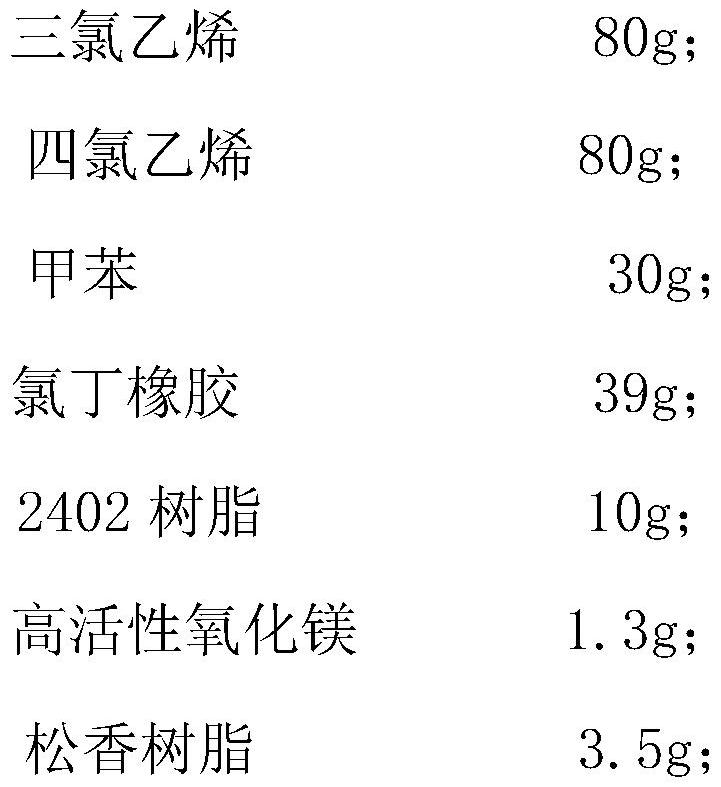

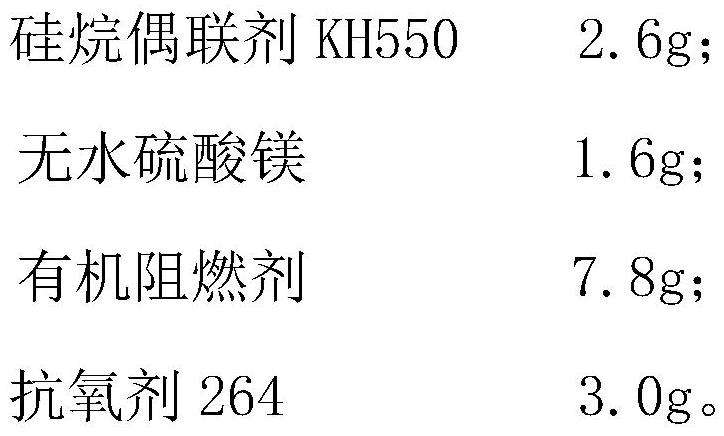

[0043] The composition ratio of a flame retardant conveyor belt repair glue:

[0044]

[0045]

[0046] The organic flame retardant is an environment-friendly halogen-free nitrogen and phosphorus compound intumescent flame retardant, and its model is Doher-6002A.

Embodiment 3

[0048] The composition ratio of a flame retardant conveyor belt repair glue:

[0049]

[0050] The organic flame retardant is an environment-friendly halogen-free nitrogen and phosphorus compound intumescent flame retardant, and its model is Doher-6002A.

[0051] Three kinds of embodiment preparation methods are identical, take embodiment 1 as example:

[0052] A. Put the solvent (trichloroethylene 90g, 1,2-dichloroethane 90g, toluene 30g) into the high-speed dispersion dynamic mixer, start stirring, and then add neoprene, tackifying resin (2402 resin, hydrogenated rosin resin) ), highly active magnesium oxide, anhydrous magnesium sulfate, organic flame retardant, antioxidant 264, stir for 6h-8h until the materials are evenly dispersed;

[0053] B. Add silane coupling agent KH550 and stir for 2 hours to 4 hours until the material is evenly dispersed to prepare a flame retardant conveyor belt repair glue.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap