High-precision magnetic imaging system and method based on TMR sensor

A high-precision, magnetic imaging technology, applied in instruments, scientific instruments, and material analysis through electromagnetic means, can solve problems such as limiting the scope of application, and achieve the effects of flexible operation, low power consumption, and simple operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

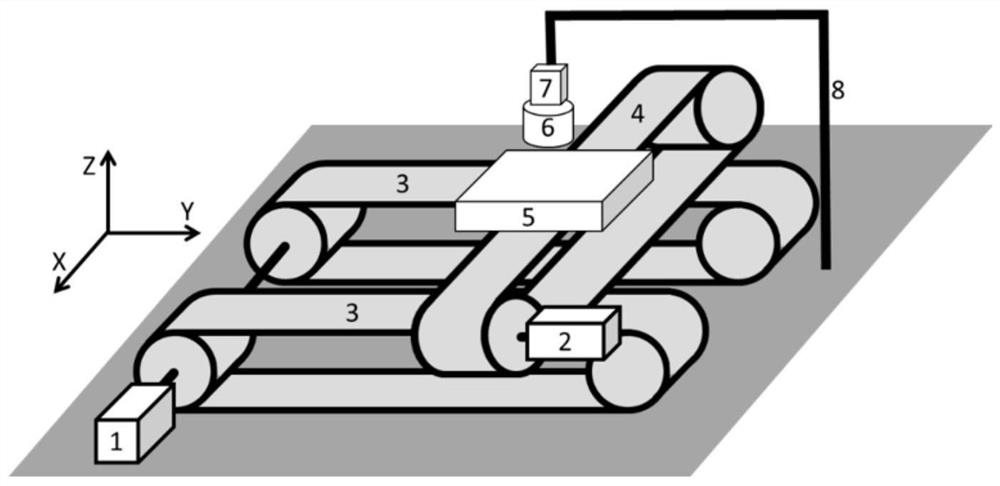

[0071] figure 1 It is a mechanical structure link method;

[0072] 1 is the X-axis stepping motor, 2 is the Y-axis stepping motor, 3 is the X-axis guide rail, 4 is the Y-axis guide rail, 5 is the liftable sample stage, 6 is the excitation coil; 7 is the full-bridge TMR linear magnetoresistive sensor, The sensitive axis is placed along the Z axis; 8 is the bracket;

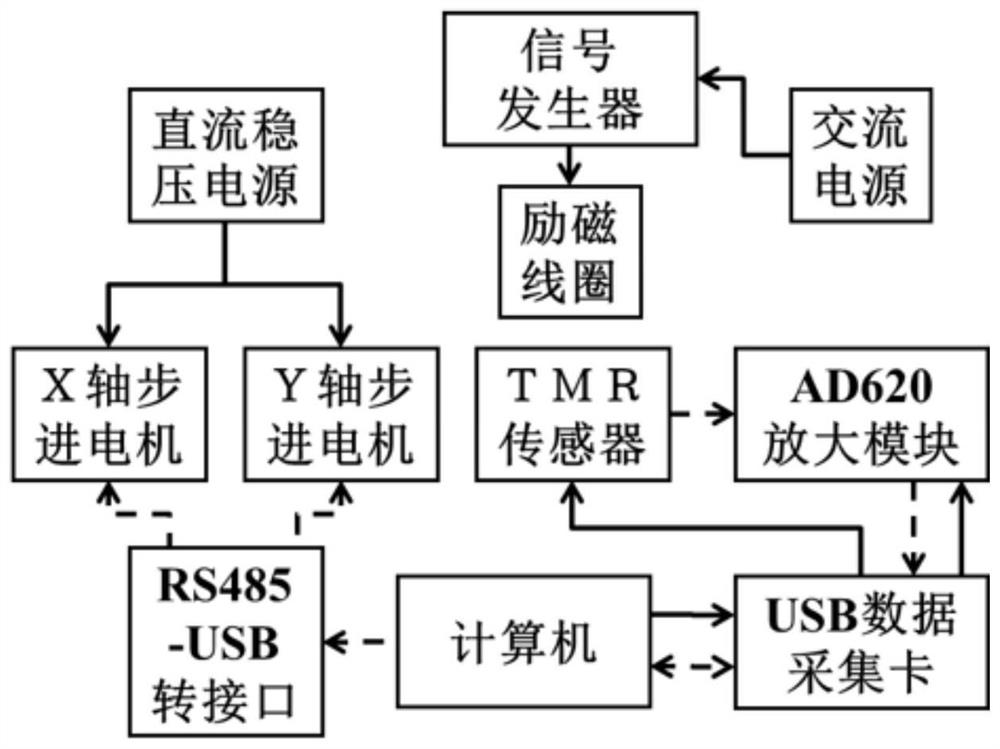

[0073] figure 2 It is the circuit and signal link mode, the solid line represents the power supply line, and the dotted line represents the signal line;

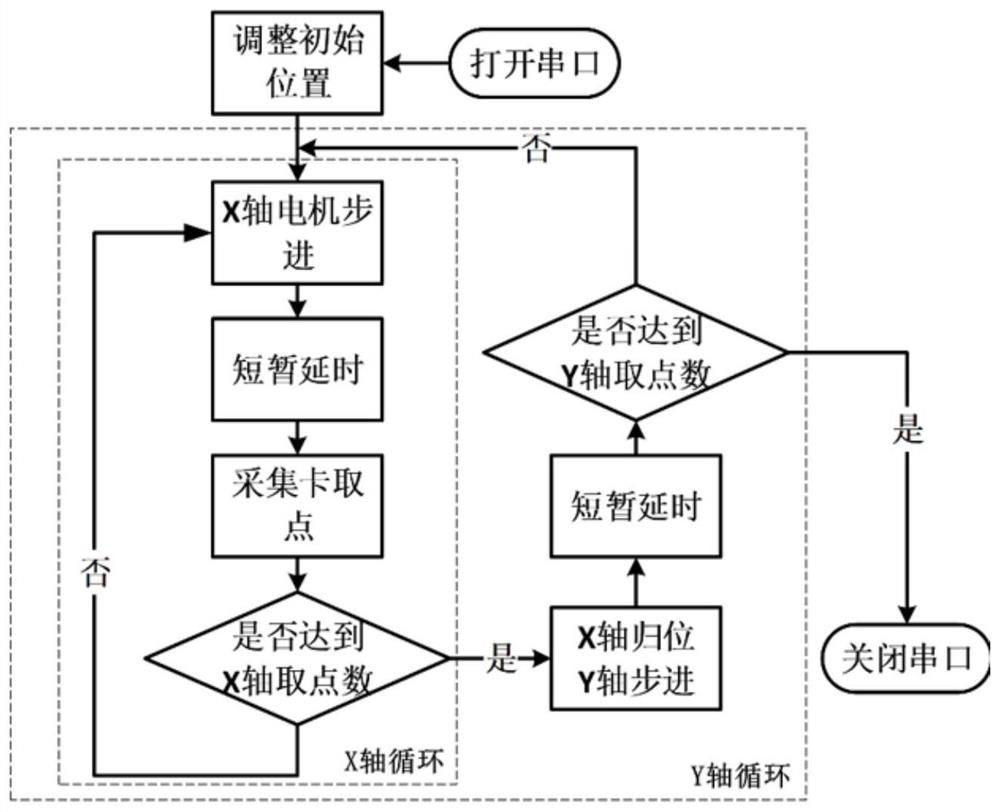

[0074] image 3 It is a basic logic structure diagram of the computer-side control program.

specific Embodiment approach

[0075] Step 1: Structure Construction

[0076] X-axis parallel double guide rails and Y-axis guide rails are vertically built, driven by X-axis and Y-axis stepping motors respectively;

[0077] The stepper motor driver adopts RS485 protocol, and is connected to the computer through the RS485 to USB interface;

[0078] The stepper motor provides +25V power supply through a DC regulated power supply;

[0079] The excitation coil provides an excitation signal through an AC signal source and applies excitation to the sample, and the axial direction is perpendicular to the sample stage, that is, along the Z-axis direction;

[0080] The TMR sensor provides 0-5V single-ended power supply through the analog output of the data acquisition card, and is placed above the excitation coil. The sensitive axis is consistent with the axis of the excitation coil, that is, along the Z-axis direction;

[0081] The AD620 amplifier module provides +5V single-ended power supply through the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com