Protein-based fat meat tissue and preparation method thereof

A protein-based, fatty meat technology, applied in the field of vegetable protein meat, can solve the problems of demulsification, difficult to cut, low melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix 5 parts of sucrose ester, 5 parts of glyceryl mono- and distearate, 2 parts of soybean protein isolate, 60 parts of coconut oil, and 28 parts of water, and homogeneously emulsify at 9500r / min for 3min at 40°C to obtain an emulsion.

[0028] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the mass ratio of emulsion to chitosan was 30:1, and the pH was adjusted to 6. The obtained mixed emulsion was placed in a 40°C water bath for 20 minutes, and solidified under low-speed stirring for two hours. The solidified sample was centrifuged (1000r / min, 5min) to collect the microcapsules (upper wet capsule).

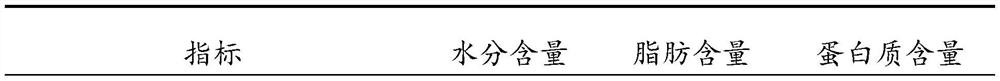

[0029] Dissolve 12% soybean protein isolate, ultrasonic degassing conditions: 45°C, 5min, mix with microcapsules at a mass ratio of 1:1, add 6% TG enzyme, heat reaction molding at 45°C for 1 hour, and obtain protein-based fat meat organize. The composition and texture of ...

Embodiment 2

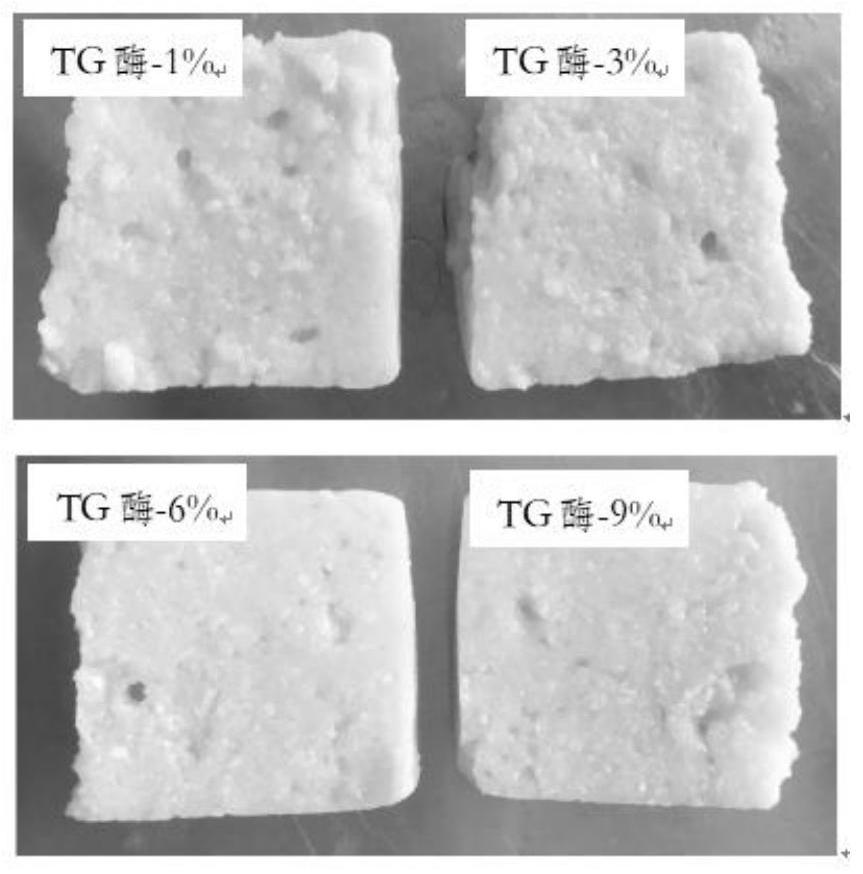

[0041] This example is to study the effect of TG enzyme content on the tissue texture of protein-based fat meat.

[0042] Mix 5 parts of sucrose ester, 5 parts of glyceryl mono- and distearate, 2 parts of soybean protein isolate, 60 parts of coconut oil, and 28 parts of water, and homogeneously emulsify at 9500r / min for 3min at 40°C to obtain an emulsion.

[0043] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the mass ratio of emulsion to chitosan was 30:1, and the pH was adjusted to 6. The obtained mixed emulsion was placed in a 40°C water bath for 20 minutes, and solidified under low-speed stirring for two hours. The solidified sample was centrifuged (1000r / min, 5min) to collect the microcapsules (upper wet capsule).

[0044] Dissolve 12% soybean protein isolate, ultrasonic degassing conditions: 45°C, 5min, and mix with microcapsules at a mass ratio of 1:1, in which TG enzym...

Embodiment 3

[0047] This example is to study the effect of the added amount of emulsifier, soybean protein isolate, coconut oil and water on the texture of protein-based fat meat.

[0048] According to the mass ratio of the emulsifier, soybean protein isolate, coconut oil and water in Table 4, they were uniformly mixed, and homogeneously emulsified at 9500r / min for 3min at 40°C to obtain an emulsion.

[0049] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the mass ratio of emulsion to chitosan was 30:1, and the pH was adjusted to 6. The obtained mixed emulsion was placed in a 40°C water bath for 20 minutes, and solidified under low-speed stirring for two hours. The solidified sample was centrifuged (1000r / min, 5min) to collect the microcapsules (upper wet capsule).

[0050] Dissolve 12% soybean protein isolate, ultrasonic degassing conditions: 45°C, 5min, mix with microcapsules at a mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com