Anthracene structure-based cavity transport material as well as preparation method and application thereof

A technology of hole transport material and chemical structural formula, which is applied in the field of hole transport materials based on anthracene structure and its preparation, can solve the problems of poor planar stacking effect, weak intermolecular force, cumbersome synthesis and purification, etc., and achieve good planar stacking The effect of enhancing hole transport ability and improving hole mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

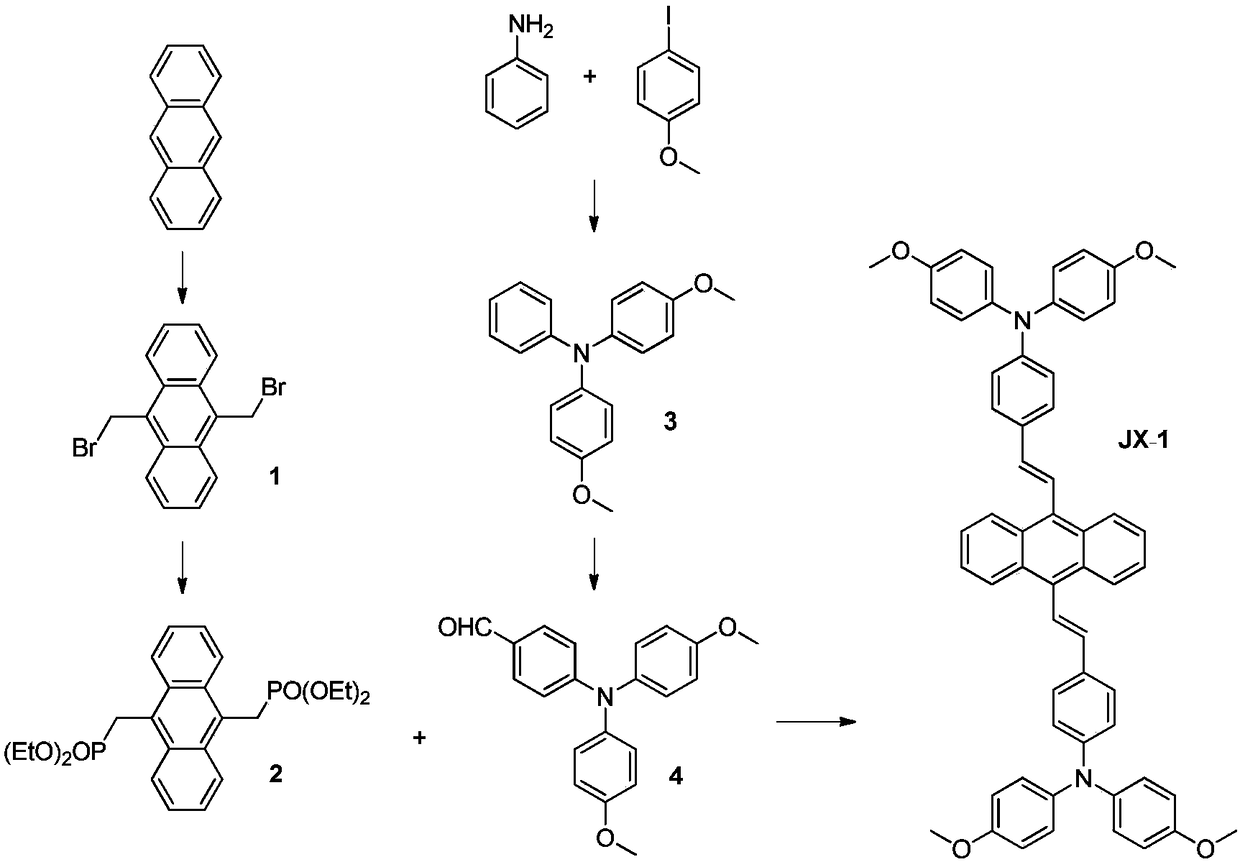

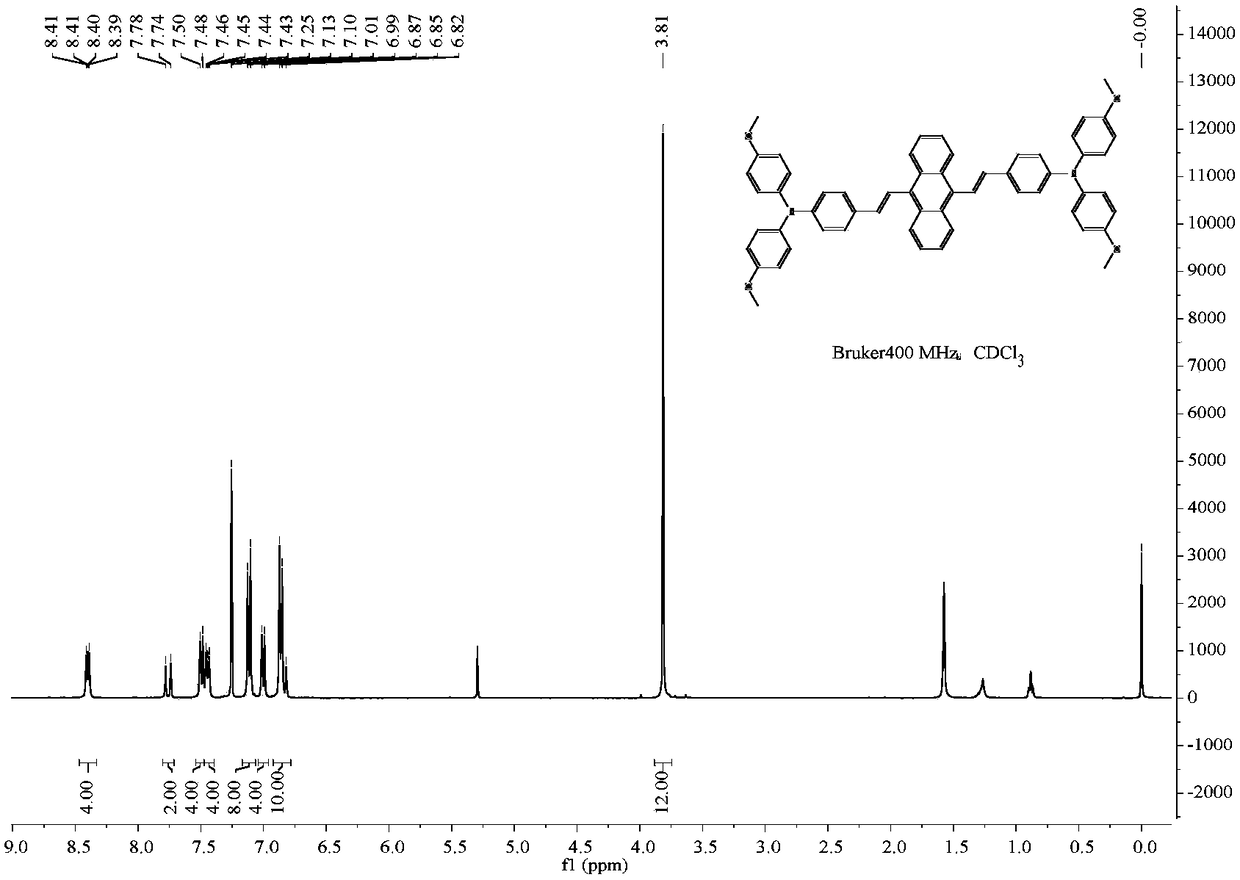

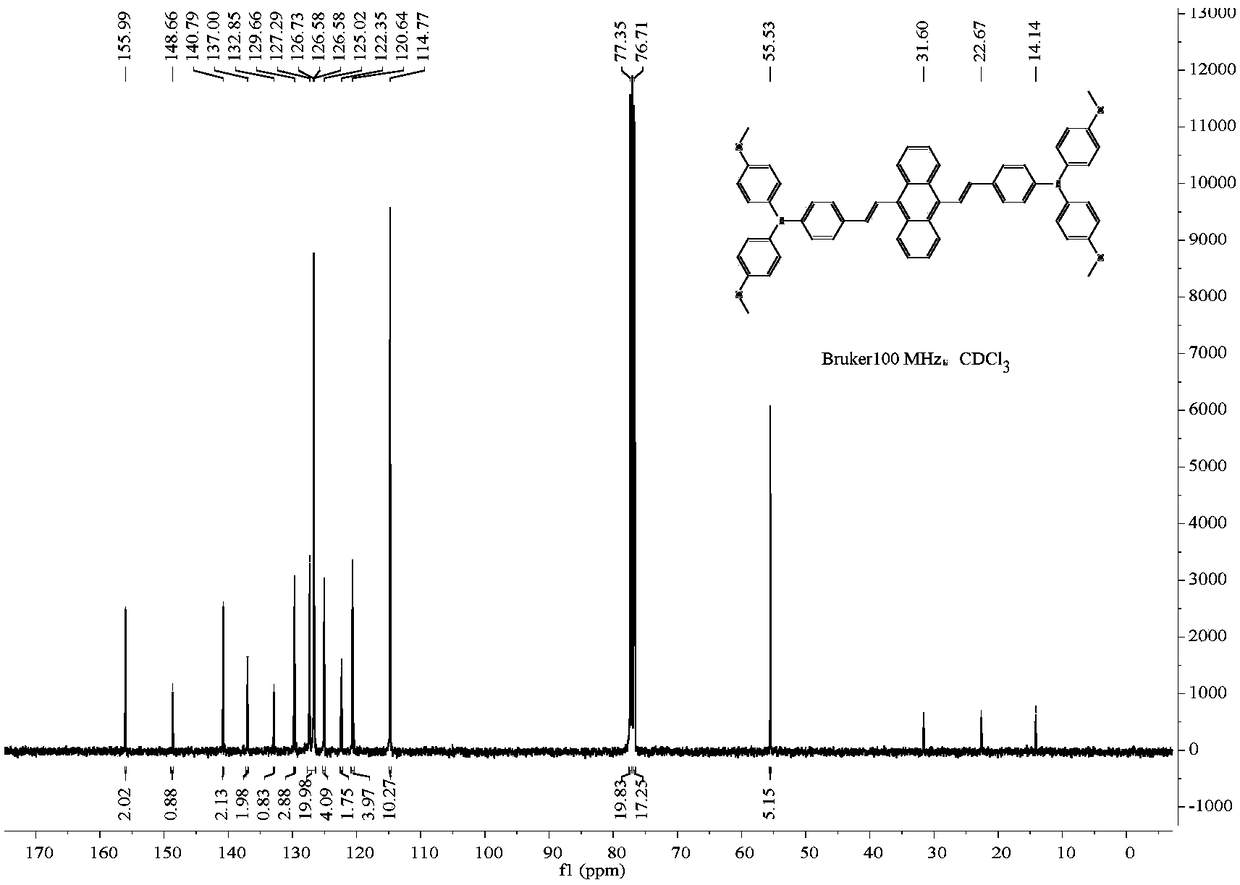

[0082] Synthesis of Example 1 Hole Transport Material JX-1

[0083] 1. Synthesis method

[0084] The specific synthesis route of JX-1, which is a hole transport material, is shown in the attached figure 1 shown.

[0085] This schematic diagram shows only an example of the synthesis method, and the method of the present invention is not limited to the related substances shown in the figure. Concrete synthetic steps are as follows:

[0086] 1. Synthesis of Compound 1

[0087]

[0088] A 50mL two-necked bottle was used as the reaction vessel, and the reaction device was subjected to anhydrous treatment under argon protection. Add anthracene (2.67g, 15mmol, 1.0eq) and paraformaldehyde (2.972g, 33mmol, 2.5eq) into the two-necked flask, ventilate, and add hydrobromic acid (5mL, 30%wt HOAc) under stirring. Reaction in an oil bath at 60°C for 12 hours. The product was spin-dried under reduced pressure. Add toluene dropwise in an oil bath at 60°C and oscillate to dissolve the c...

Embodiment 2

[0103] The preparation of embodiment 2 perovskite solar cells

[0104] 1. Synthesis method

[0105] A kind of perovskite solar cell, its preparation method specifically comprises the following steps:

[0106] 1. Soak FTO glass in ethanol for later use. Take out and protect part of the conductive layer with adhesive tape, and etch the empty part with zinc powder and hydrochloric acid (4mol / L). Sonicate with detergent in deionized water, deionized water, acetone, and ethanol in sequence. Soak in ethanol for later use.

[0107] 2. Take out the FTO glass treated in step 1 from ethanol, and spin-coat TiO on the surface of FTO 2 Sol, controlled conditions (3000rpm, 40s), and fired at 500°C for 1 hour.

[0108] 3. Take out the FTO glass treated in step 2 and soak it in TiCl after cooling 4 Hydrolysis solution (2.2 mLTiCl 4 dissolved in 500 mL of deionized water), and placed at 70°C for 0.5 hours. After taking it out, rinse it with deionized water and ethanol in turn, and burn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com