Sewage treatment method

A sewage treatment method and sewage technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor impact resistance of flocs, short storage time of flocs, low COD removal rate, etc. The effect of long storage time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

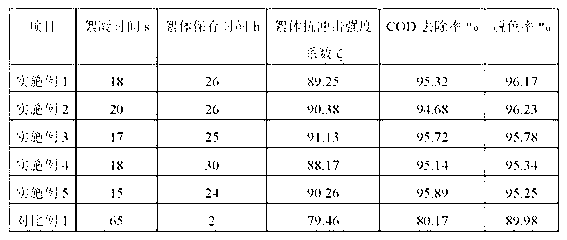

Examples

Embodiment 1

[0018] Take 150 g of anhydrous aluminum chloride, slowly add 750 ml of ultrapure water after pulverization, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an aluminum chloride solution with a mass ratio of 20%; then take ammonium carbonate 50g, put it into a dissolving tank, add 250 ml of ultrapure water, and stir fully to make it fully dissolve into a 20% ammonium carbonate solution with a mass ratio. Then put the prepared aluminum chloride solution and ammonium carbonate solution into a compounding tank at a volume ratio of 1:0.8, and stir vigorously to fully mix the two solutions to obtain polyaluminum chloride for later use. Take 150g of acrylamide, slowly add 750ml of ultrapure water, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an acrylamide solution with a mass ratio of 20%; take 150g of acrylic acid, slowly add 750ml of ultrapure water , so that it is fully dissolved into an acrylic a...

Embodiment 2

[0021] Take 150 g of anhydrous aluminum chloride, slowly add 750 ml of ultrapure water after pulverization, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an aluminum chloride solution with a mass ratio of 20%; then take ammonium carbonate 50g, put it into a dissolving tank, add 250ml of ultrapure water, and stir fully to make it fully dissolve into a 20% ammonium carbonate solution by mass ratio. Then put the prepared aluminum chloride solution and ammonium carbonate solution into a compounding tank at a volume ratio of 1:1.5, and stir vigorously to fully mix the two solutions to obtain polyaluminum chloride for later use. Take 150g of acrylamide, slowly add 750ml of ultrapure water, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an acrylamide solution with a mass ratio of 20%; take 150g of acrylic acid, slowly add 750ml of ultrapure water, and make It is fully dissolved into an acrylic acid s...

Embodiment 3

[0024] Take 150 g of anhydrous aluminum chloride, slowly add 750 ml of ultrapure water after pulverization, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an aluminum chloride solution with a mass ratio of 20%; then take ammonium carbonate 50g, put it into a dissolving tank, add 250ml of ultrapure water, and stir fully to make it fully dissolve into a 20% ammonium carbonate solution by mass ratio. Then put the prepared aluminum chloride solution and ammonium carbonate solution into a compounding tank with a volume ratio of 1:1, and stir vigorously to fully mix the two solutions to obtain polyaluminum chloride for later use. Take 150g of acrylamide, slowly add 750ml of ultrapure water, put it into a dissolving tank, start a magnetic stirrer, and make it fully dissolve into an acrylamide solution with a mass ratio of 20%; take 150g of acrylic acid, slowly add 750ml of ultrapure water, and make It is fully dissolved into an acrylic acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com