Efficient automatic bending device for building rubber plate detection

A bending device and rubber sheet technology, applied in the field of building materials, can solve the problems of high degree of manual intervention, low work efficiency, limited number of processing, etc., and achieve the effect of high degree of automation, high work efficiency, and increased linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

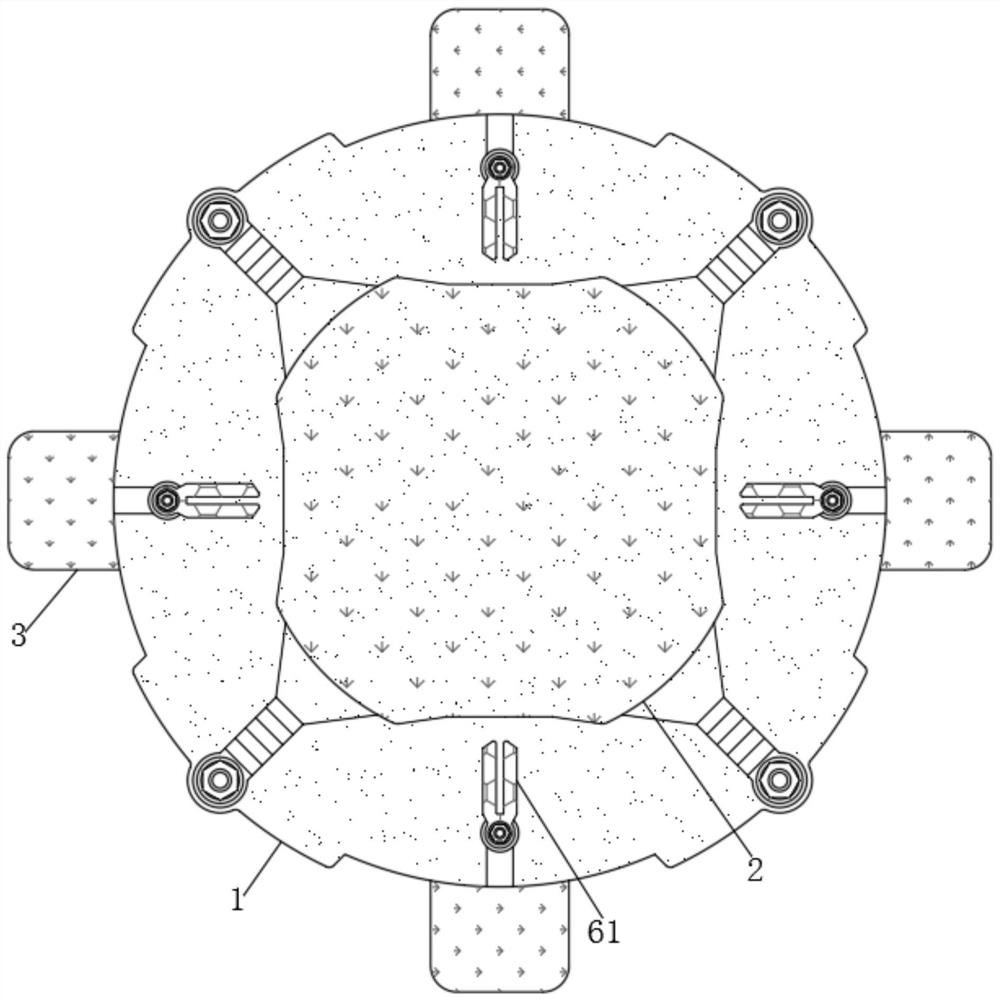

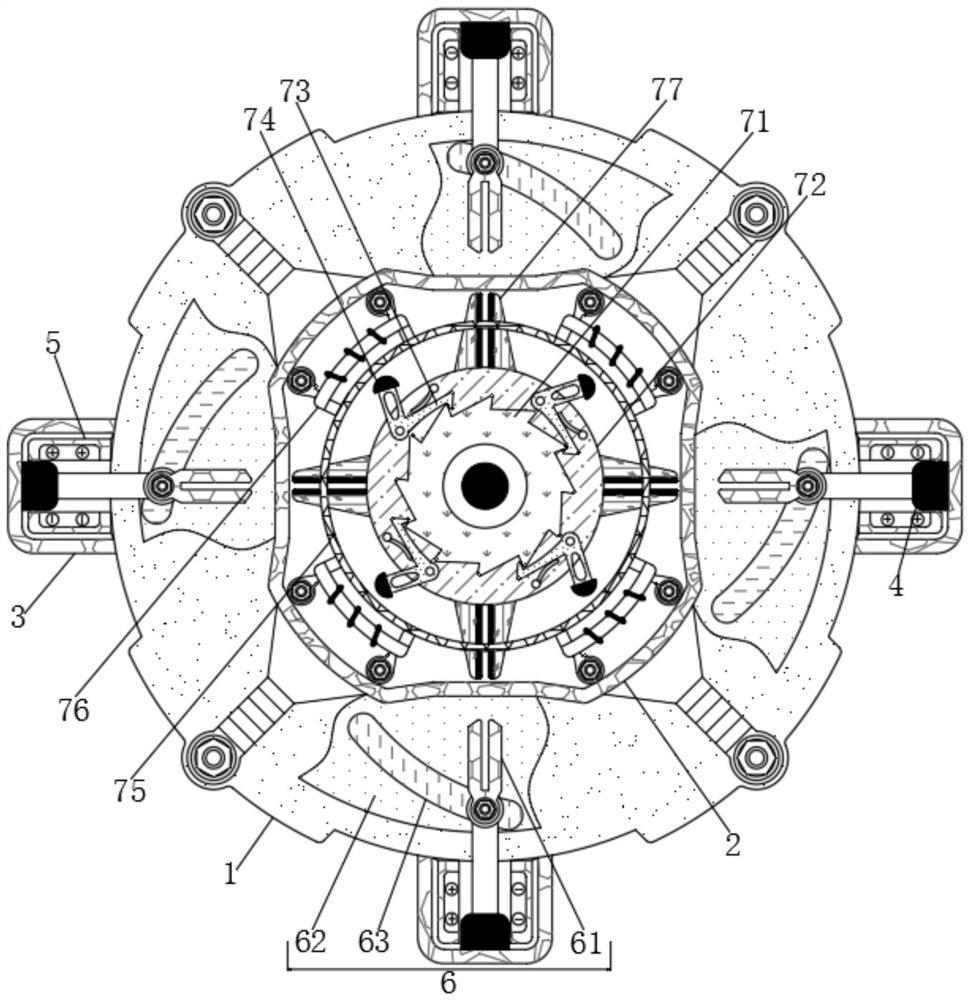

[0025] see Figure 1-3 , a high-efficiency automatic bending device for construction rubber plate detection, including a placing table 1, an upper shell 2, a frame 3, a dielectric plate 4, a pole plate group 5, a moving mechanism 6 and a bending mechanism 7.

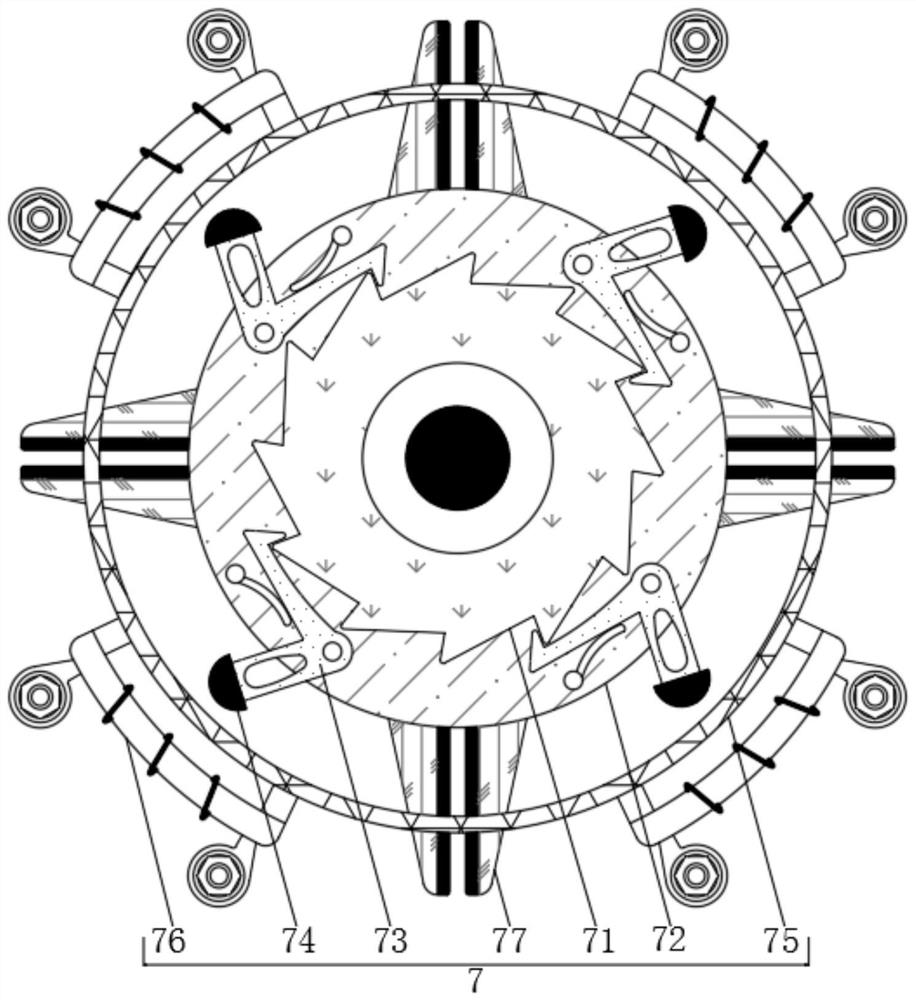

[0026] The bending mechanism 7 includes a ratchet 71, the outer side of the ratchet 71 is connected with a rotating plate 72, the surface of the rotating plate 72 is rotatably connected with a linkage rod 73, and the outer side of the linkage rod 73 is fixedly connected with a metal block 74, and the metal block 74 is far away from the rotating body. One side of plate 72 center is provided with magnetic conduction circle 75, and the outside of magnetic conduction circle 75 is fixedly connected with electromagnet 76, and the outside of rotating plate 72 is fixedly connected with plug plate 77, and the outside of ratchet wheel 71 is fixedly connected with motor, and The drive is electrically connected with the dielectric p...

Embodiment 2

[0029] see Figure 1-3 , a high-efficiency automatic bending device for construction rubber plate detection, including a placing table 1, an upper shell 2, a frame 3, a dielectric plate 4, a pole plate group 5, a moving mechanism 6 and a bending mechanism 7.

[0030] The moving mechanism 6 includes a card frame 61. The outer side of the card frame 61 is rotatably connected with a turntable 62. The surface of the turntable 62 is provided with an arc groove 63. The card frame 61 presents a concave shape. There are four card frames 61 with the same specification, and the outside The insulating rods of the dielectric plate 4 are fixedly connected, the card frame 61 is provided with a card column near the side of the placing table 1, the outer side of the turntable 62 is provided with a forward and reverse motor, and there are four arc grooves 63 with the same specification. The four arc grooves 63 Equidistantly distributed on the surface of the turntable 62, the size of the arc gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com