Cavity film with film stretching frames and cavity film hollow glass

A stretch film frame and cavity technology, applied in the field of continuous production equipment, can solve problems such as the complex structure of the diaphragm insulating glass, the difficulty of combined packaging and processing, and the impact on the effect of heat insulation, etc., to solve the problem of corner wrinkling and middle part Effects of collapse, reduced manufacturing costs, and improved productivity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

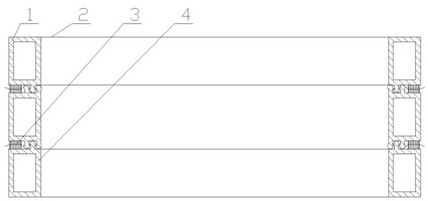

Embodiment 1

[0054] Example 1: Reference figure 1 A cavity film having a flux frame comprising a spacer frame 1, two diaphragm 2, and two strand frames 4, two of the four sides of the diaphragm 2 are fixed to the interval On the frame 1, the remaining two pairs are not fixed in a free state, or the four edges of the separator 2 are fixed to the space frame 1, four corners or not fixed, the angle is made by cut angles, punching or slots. The portion is free, preventing a wrinkle in the corner of the diaphragm; the two diaphragms 2 are fixed to both sides of the spacer frame 1, the diaphragm 2, the spacer frame 1 and the separator 2 form a cavity, which constitutes a cavity film; two The outer side of the diaphragm 2 has a flirtraum frame 4, and the spacing frame 1 is mounted on the surface of the sliding frame 4, and the convex and concave structure is located in the inside of the diaphragm 2, in the sliding frame 4 and the interval. When the frame 1 is pressed, the convex and concave structure...

Embodiment 2

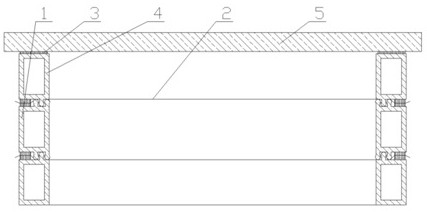

[0056] Example 2: Reference figure 2 A single glass cavity film made of a cavity film having a flux frame, including a glass 5 and a cavity film having a slacete frame, cavity film having a flip frame and glass 5 by sealing The glue 3 is bonded together into a single glass cavity membrane in hollow glass.

[0057] The monolithic cavity of the monochrome cavity can be used directly to create a flat solar water heater cover or a freezer or an insulation plate of the wine cabinet or a thermal glass in which a double glass cavoline can be used.

Embodiment 3

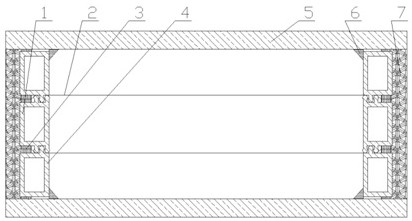

[0058] Example 3: Reference image 3 A double glass cavity membrane manufactured by a slope frame and cavity membrane, including two glass 5, two strand frames 4, and a cavity film, first fabricated in Example 1. 4 and a cavity film, then produce two kinds of glass 5, and then applied to the sealing glue 3 on both sides of the two flip frames 4, fixed on two glass 5, and in the flunter frame 4 The inner ring or outer ring is placed onto the glass contact, so that the slacete frame 4 is quickly firmly bonded to the glass 5, preventing the slacete of the slimming frame 4 from moving; Two pieces of glass 5 with the sliding frame 4 are pressed, and the convex and concave structure on the space frame 1 and the slacete 4 is simultaneously fitted with each other, and the film 5 and the stretch The structural adhesive 7 is applied in the space formed in the outer side of the membrane frame 4 and the cavity film, and the structural adhesive 7 can be used with silicone or polysulfide or hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com