Ionic membrane caustic soda first-effect evaporation device and method

An ion-membrane caustic soda and high-efficiency evaporation technology, applied in the field of caustic soda evaporation, can solve problems such as the inability of the evaporation system to run normally, the product concentration cannot be reached, and the production capacity of the device is affected, so as to reduce the maintenance and repair workload, and the production guarantee is strong and not easy. The effect of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The scheme of the patent of the present invention will be described in detail below in conjunction with specific examples.

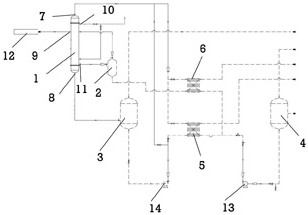

[0018] Such as figure 1 , an ionic membrane caustic soda one-effect evaporator, comprising a first-effect evaporator 1, a condensed water tank 2, a first-effect separator 3, a second-effect separator 4, a first-stage preheater 5 and a second-stage preheater 6, the evaporator It is a shell and tube falling film evaporator, the top of the evaporator is provided with a feed liquid inlet 7, the feed liquid inlet is connected with a feed liquid input pipe, the bottom is provided with a concentrated liquid outlet 8, the concentrated liquid outlet is connected with a concentrated liquid output pipe, and the middle part of the evaporator is provided with Steam inlet 9, tail gas discharge port 10, condensed water discharge port 11, the steam inlet is connected to the steam boiler 12, the condensed water discharge port is connected to the condensed water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com