Extraction separation tank of phosphoric acid purification device

A purification device and separation tank technology, which is applied to phosphorus compounds, separation methods, solvent extraction, etc., and can solve problems such as hidden dangers, partial flow caused by partition overflow, and unstable overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

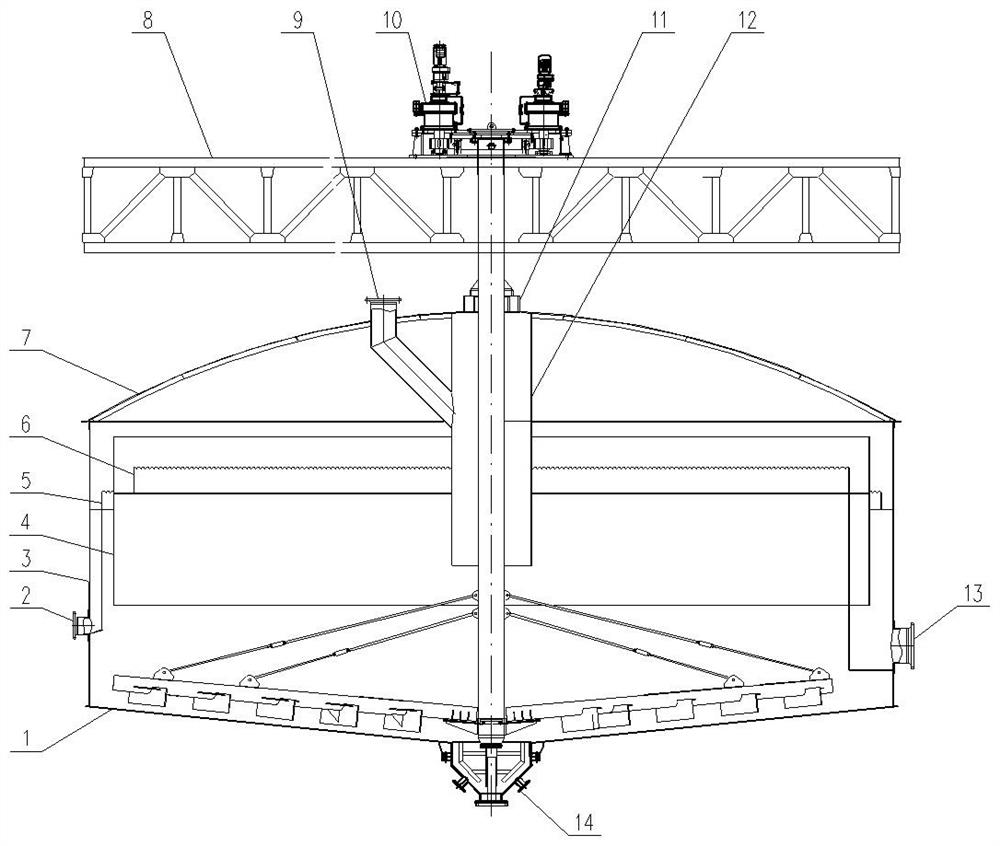

[0028] The structure of the extraction and separation tank of a phosphoric acid purification device of the present invention is as follows: figure 1 As shown, the extraction and separation tank of the phosphoric acid purification device of this embodiment includes a tank body 3 and a tank rake 10, the upper part of the tank body 3 is provided with a tank top 7, and the lower part has a tank bottom 1, and the tank bottom 1 is provided with a slag outlet 14 , the groove rake 10 is rotatably installed with a stirring shaft that passes from the groove top 7 into the tank body 3, and the stirring shaft is fixedly connected with a stirring paddle at the lower part of the tank body 3. The inner cylinder 4 is an open structure, the stirring shaft passes through the inner cylinder 4, and the inner cylinder 4 is provided with a guide tube 12 arranged v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com