Strip shape control method for hot continuous rolling of titanium and titanium alloy strip coils

A flatness control, titanium alloy coil technology, applied in metal rolling, profile control, metal rolling and other directions, can solve the problems of surface quality defects, difficult control, inability to process, etc., to reduce the cooling rate and prolong slow cooling. time, the effect of reducing C warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

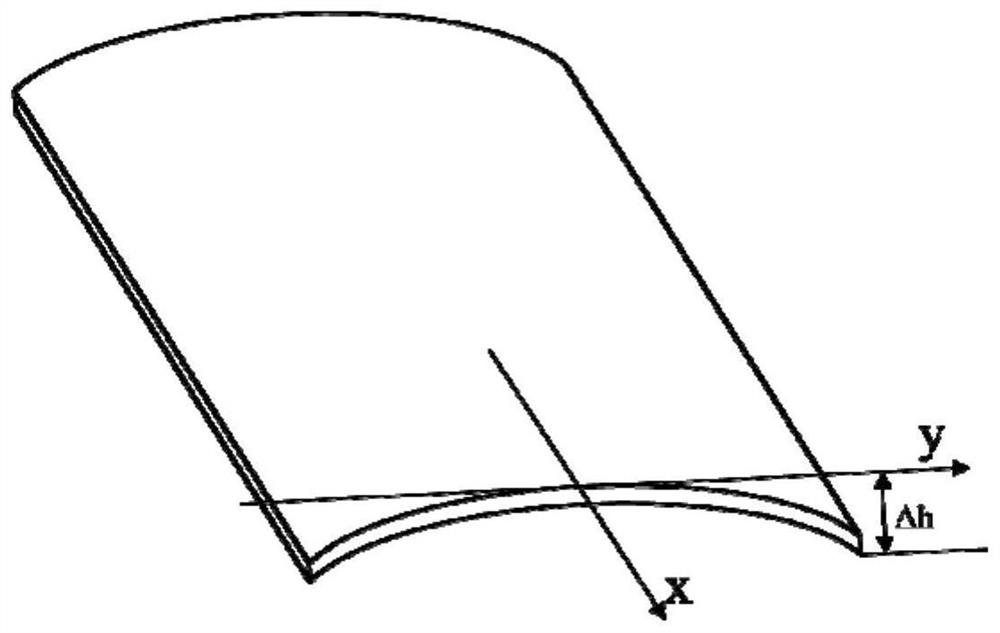

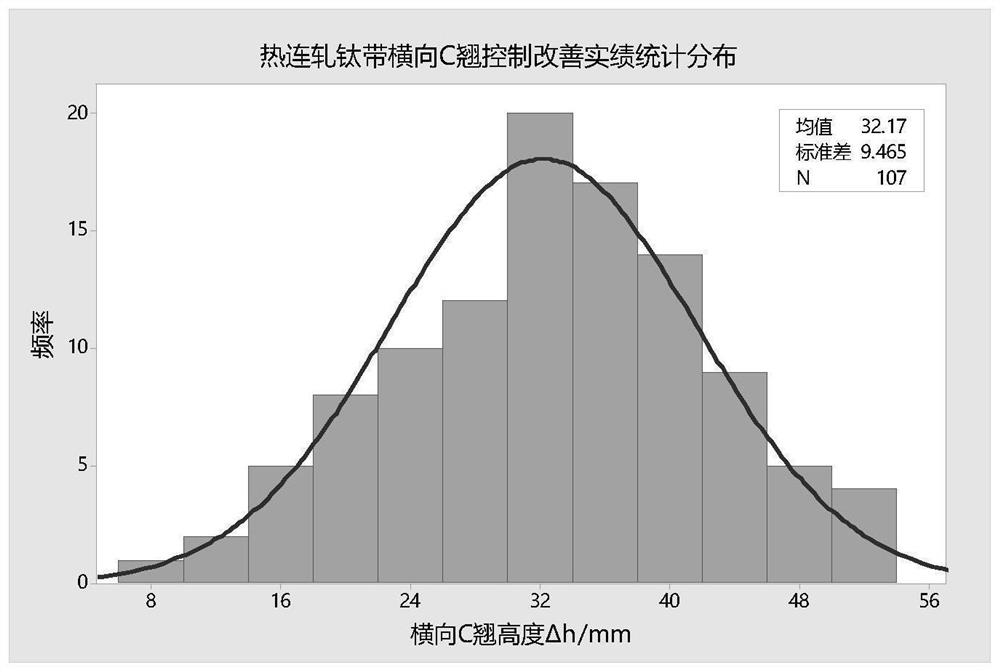

[0035] A steel and vanadium company used the above-mentioned technology to roll 3383.71 tons of titanium and titanium alloy strips and coils within three years. The transverse C-warp defect and defect degree of titanium and titanium alloy coils have been effectively controlled and improved, and the transverse C-warp height value Δh has been reduced from 120-150mm before, and even more than 200mm, to below 50mm, the average value 32.17mm, the specific improvement statistics are as follows figure 2 As shown, the transverse C-warping defect degree of titanium and titanium alloy coils has been greatly improved, thereby improving the product quality and use quality of titanium and titanium alloy coils, and the products can well meet the use requirements of subsequent finishing and deep processing. This technology overcomes and solves the common technical difficulties in the field of hot continuous rolling of titanium and titanium alloys, and has broad application prospects in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com