A kind of thermal protection structure and preparation method thereof

A heat protection structure and heat insulation layer technology, applied in chemical instruments and methods, aerospace vehicle heat protection devices, metal layered products, etc., can solve problems such as difficult to meet the needs of heat protection, achieve excellent heat protection performance, Realize the effect of repeated use and recovery of thermal protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

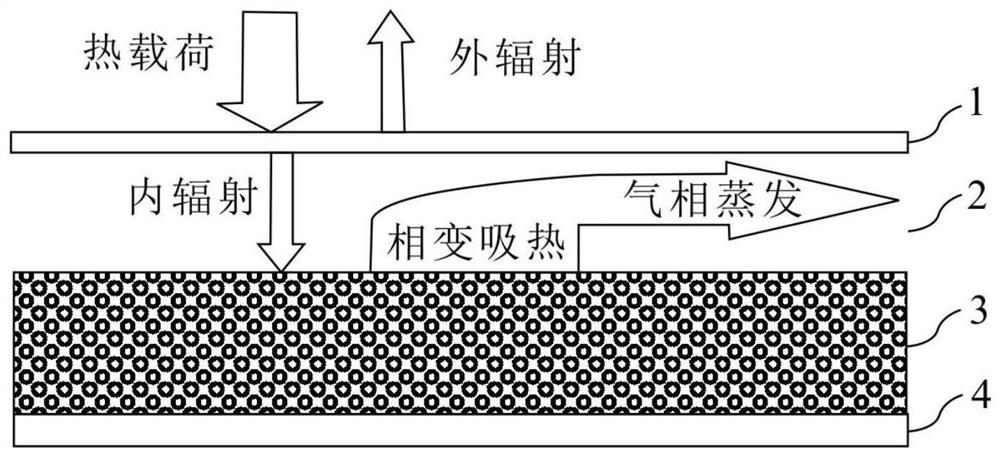

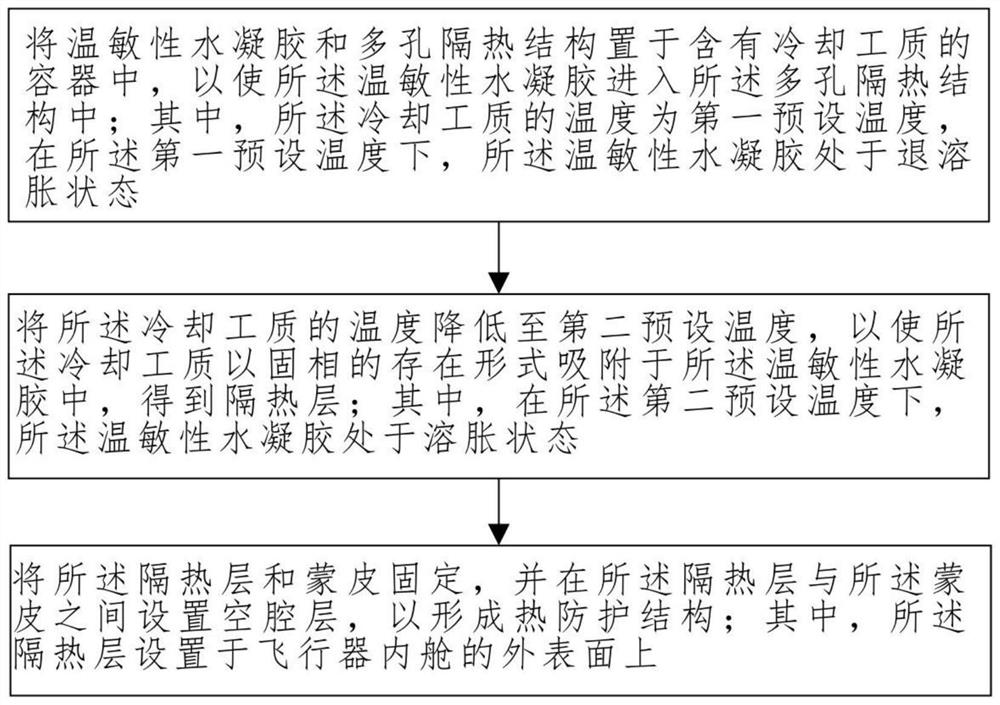

[0073] like figure 2 As shown, the present invention also provides a preparation method of a thermal protection structure, comprising:

[0074]The temperature-sensitive hydrogel and the porous thermal insulation structure are placed in a container containing a cooling medium, so that the temperature-sensitive hydrogel enters the porous thermal insulation structure; wherein the temperature of the cooling medium is a first preset temperature , at the first preset temperature, the temperature-sensitive hydrogel is in a de-swelling state;

[0075] lowering the temperature of the cooling working medium to a second preset temperature, so that the cooling working medium is adsorbed in the temperature-sensitive hydrogel in the form of a solid phase to obtain a thermal insulation layer; wherein, at the second preset temperature, The thermosensitive hydrogel is in a swollen state;

[0076] The heat insulation layer and the skin are fixed, and a cavity layer is arranged between the he...

Embodiment 1

[0091] The temperature-sensitive hydrogel and the porous alumina ceramic plate of 100mm × 100mm × 8mm were placed in a container containing distilled water, so that the temperature-sensitive hydrogel entered the porous alumina ceramic plate; wherein, the temperature of the distilled water was 36 ℃, the thermosensitive hydrogel is in a deswelling state;

[0092] lowering the temperature of the distilled water to 25°C, so that the distilled water is adsorbed in the temperature-sensitive hydrogel in the form of a solid phase to obtain a thermal insulation layer; wherein, the temperature-sensitive hydrogel is in a swollen state;

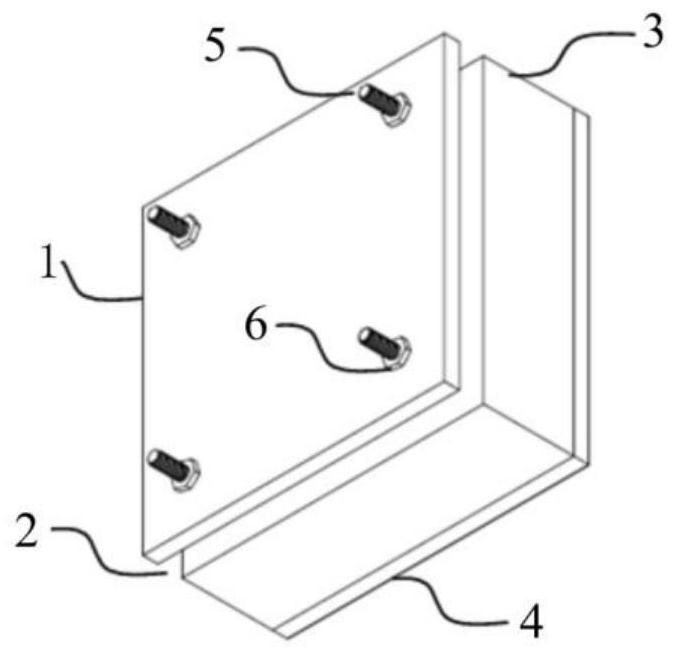

[0093] The heat insulation layer, the skin and the bottom plate are fixed by means of screws and nuts to obtain the bottom plate of the thermal protection structure. Among them, the skin is made of 100mm×100mm×5mm high temperature alloy plate, the bottom plate material is made of 100mm×100mm×5mm aluminum alloy plate, and the screw nuts are M4 alumina cer...

Embodiment 2

[0096] The preparation method of embodiment 2 is basically the same as that of embodiment 1, and the difference is:

[0097] The heat flux density is 0.1MW / m 2 , the thickness of the porous alumina ceramic plate is 5mm.

[0098] The measured outer surface temperature of the skin is 420 °C, and the effective time of the active thermal protection mechanism is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com