Preparation method of high-conversion-rate and high-purity N-vinyl acetamide without catalyst.

A technology of vinylacetamide and high conversion rate, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of high thermal cracking temperature, increase the yield, and avoid acid-base neutralization The effect of dealing with the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

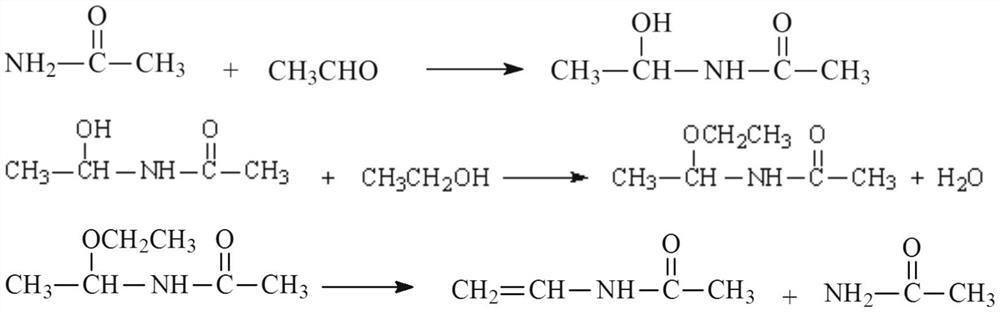

[0031] The first aspect of the present invention provides a catalyst-free, high-conversion, high-purity N-vinylacetamide preparation method, including at least one of the following two methods:

[0032] High-temperature and high-pressure method: using acetaldehyde, acetamide, and ethanol as raw materials, under airtight conditions, first preheating at low temperature, then heating at high temperature, and reacting to obtain N-vinylacetamide;

[0033] Or use a pipeline reactor: use acetaldehyde, acetamide, and ethanol as raw materials, react in a pipeline reactor, and then obtain N-vinylacetamide by distillation under normal pressure and under reduced pressure.

[0034] The two methods belong to the same technical idea, and both improve the conversion rate and purity of N-vinylacetamide by controlling physical parameters.

[0035] In the high temperature and high pressure method:

[0036] It is carried out in a closed environment with high temperature and high pressure, such a...

experiment example 1

[0087] Low temperature and normal pressure method: Add 41.8g of acetaldehyde, 28g of acetamide, 25g of ethanol, and 0.5g of concentrated sulfuric acid (catalyst) into a 250mL three-necked flask, put it in a water bath, the temperature of the water bath is 6°C, and after stirring for 12 hours, GC analysis shows , the reaction cannot proceed, and there is no reaction between the substances.

experiment example 2

[0089] High temperature and normal pressure method: Add 42g of acetaldehyde, 28.3g of acetamide, 25.1g of ethanol, 0.5g of concentrated sulfuric acid (catalyst) into a 250mL three-necked flask, put it in an oil bath, set the temperature of the oil bath to 200°C, and stir for 12 hours , GC analysis showed that although there was a reaction between the various substances, the conversion rate of acetamide was only 11.3%. Since this reaction is an equilibrium reaction, the reaction cannot continue to the right under this condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com