Electrostatic eliminating reagent for hot box of elasticizer and preparation method of electrostatic eliminating reagent

A static electricity removal and texturing machine technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of the quality stability of finished knitted gray fabrics, the lack of attention to the compatibility of elastic fibers, and the long storage time of knitted gray fabrics, etc., to achieve The effect of retaining the original state and performance, good hydrolytic stability and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

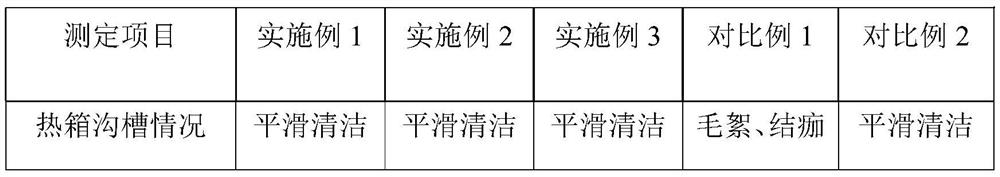

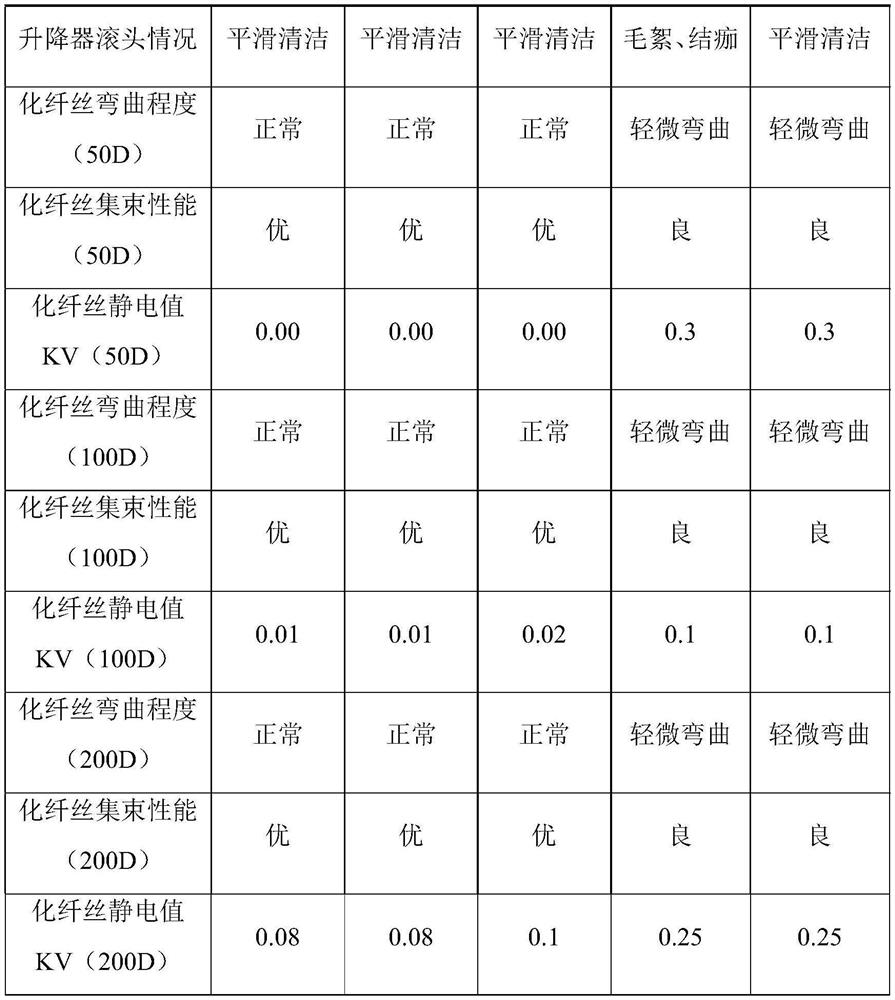

Examples

Embodiment 1

[0033] A static electricity removing agent for a texturing machine hot box, consisting of polyol ester base oil, antioxidant, antistatic agent and rust inhibitor; the polyol ester base oil accounts for 22% of the mass of the static electricity removing agent; The antioxidant accounts for 1.5% of the mass of the static-removing agent; the anti-static agent accounts for 76% of the mass of the static-eliminating agent; and the antirust agent accounts for 0.5% of the mass of the static-eliminating agent.

[0034] Wherein, the antioxidant is 2,6-tertiary butyl-4-methylphenol; the rust inhibitor is dodecenylsuccinic acid; the antistatic agent is monoalkyl ether phosphate potassium salt .

[0035] The preparation method of the destaticizing reagent in the hot box of the texturing machine comprises the following steps:

[0036] ① Weigh each reaction substance according to the mass percentage;

[0037] ②Add an antistatic agent into the reaction kettle, and stir at a speed of 60r / min ...

Embodiment 2

[0043] A static electricity removing agent for a texturing machine hot box, composed of polyol ester base oil, antioxidant, antistatic agent and rust inhibitor; the polyol ester base oil accounts for 21% of the mass of the static electricity removing agent; The antioxidant accounts for 0.5% of the mass of the static-removing agent; the anti-static agent accounts for 78% of the mass of the static-eliminating agent; and the antirust agent accounts for 0.5% of the mass of the static-eliminating agent.

[0044] Wherein, the antioxidant is 2,6-tertiary butyl-4-methylphenol; the rust inhibitor is dodecenylsuccinic acid; the antistatic agent is monoalkyl ether phosphate potassium salt .

[0045] The preparation method of the destaticizing reagent in the hot box of the texturing machine comprises the following steps:

[0046] ① Weigh each reaction substance according to the mass percentage;

[0047] ②Add an antistatic agent into the reaction kettle, and stir at a speed of 60r / min fo...

Embodiment 3

[0053] A static electricity removing agent for a texturing machine hot box, consisting of polyol ester base oil, antioxidant, antistatic agent and rust inhibitor; the polyol ester base oil accounts for 24% of the mass of the static electricity removing agent; The antioxidant accounts for 0.8% of the mass of the static removing agent; the antistatic agent accounts for 75% of the mass of the static removing agent; the antirust agent accounts for 0.2% of the mass of the static removing agent.

[0054] Wherein, the antioxidant is 2,6-tertiary butyl-4-methylphenol; the rust inhibitor is dodecenylsuccinic acid; the antistatic agent is monoalkyl ether phosphate potassium salt .

[0055] The preparation method of the destaticizing reagent in the hot box of the texturing machine comprises the following steps:

[0056] ① Weigh each reaction substance according to the mass percentage;

[0057] ②Add an antistatic agent into the reaction kettle, and stir at a speed of 60r / min for 2 to 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com