Bending-dominated pressure spring type lattice structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

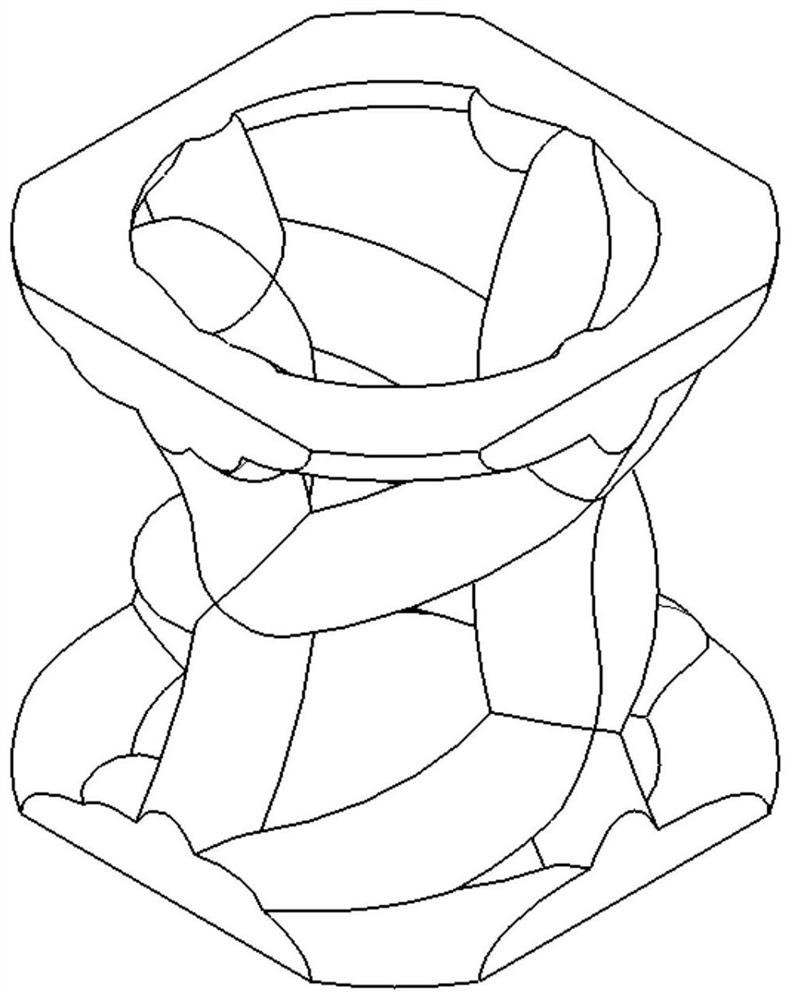

[0049] Example 1: Two-concuffing single cells and dot matrix structures

[0050] like figure 1 , figure 2 As shown: Each point of the cell is included in four curved support rods, two spiral links. The detailed implementation process is as follows: Using the three-dimensional modeling software CATIA V5, on the square of 5mm × 5mm × 5mm square, it is parallel to the four sides of the XOY plane (such as points (2.5, 0, 0), (2.5, 0, 5)) The circle having a diameter of 5 mm is established on both planes.

[0051] Create a point (1.5, 0, 0.5), then curve three points (2.5, 0, 5), (1.5, 0, 2.5), and connect the curved support rod, which can be obtained. Also bent rod. With the contour of the curved support, the point (2.5, 0, 0) is the starting point, the extension shaft is the z-axis, the pitch is 5mm, the direction is counterclockwise, establishes a spiral rod, and other spiral rods are used.

[0052] Different cross-sectional treatments for different relative densities, the cross-sec...

Embodiment 2

[0055] Example 2: Two-concuffing cell optimization treatment:

[0056] Import the two plunge cell structure into the Abaqus software for compression experimental simulation analysis, resulting in a stress distribution map, such as Figure 4 As shown, the stress distribution cloud map is compressed to 16%, as shown in the figure, the stress is mainly distributed on the curved support bar, and the two spiral support rods are less responsive, resulting in uneven stress distribution, for the cell and It has a big impact on the compression performance of the dot matrix.

[0057] Analysis of the interposed cloud map of two plunge cells, mainly optimized the spiral support rod: increase the pitch, increased to 20 mm, which is 20mm, while increasing the number of spiral connectors is 4 Root, making the cell structural stress distribution more uniform, and at the same time reduce the curved support lever curve to a certain extent, the stress distribution cloud Figure 8 Indicated.

Embodiment 3

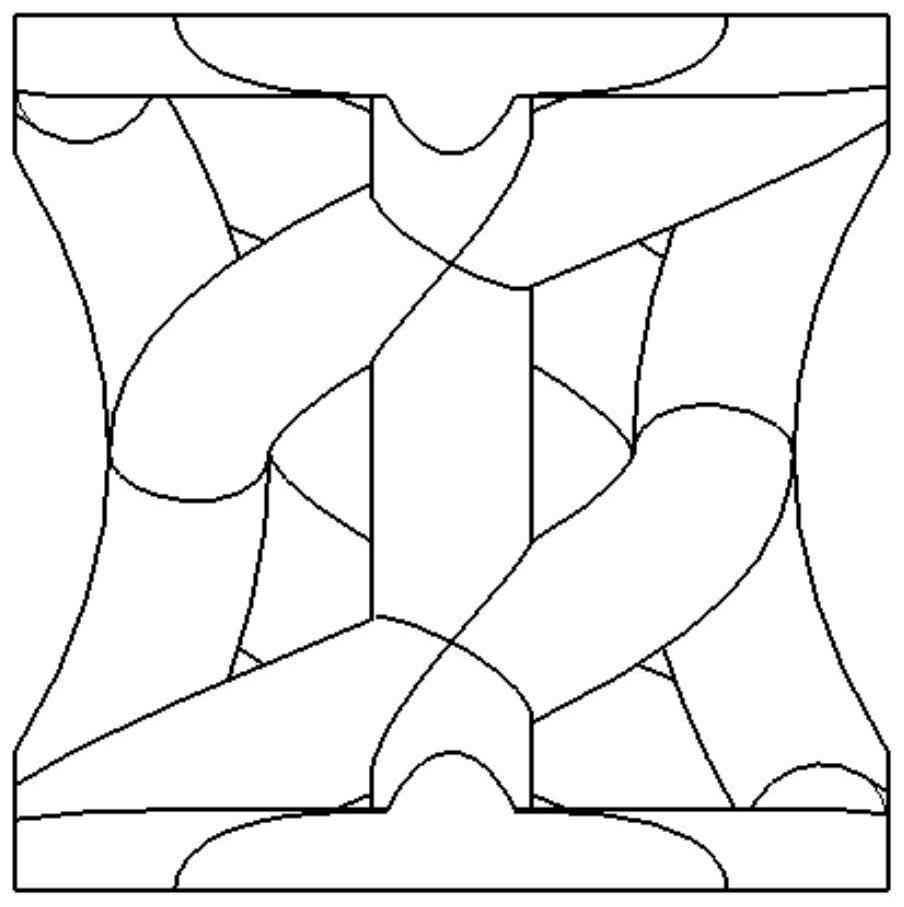

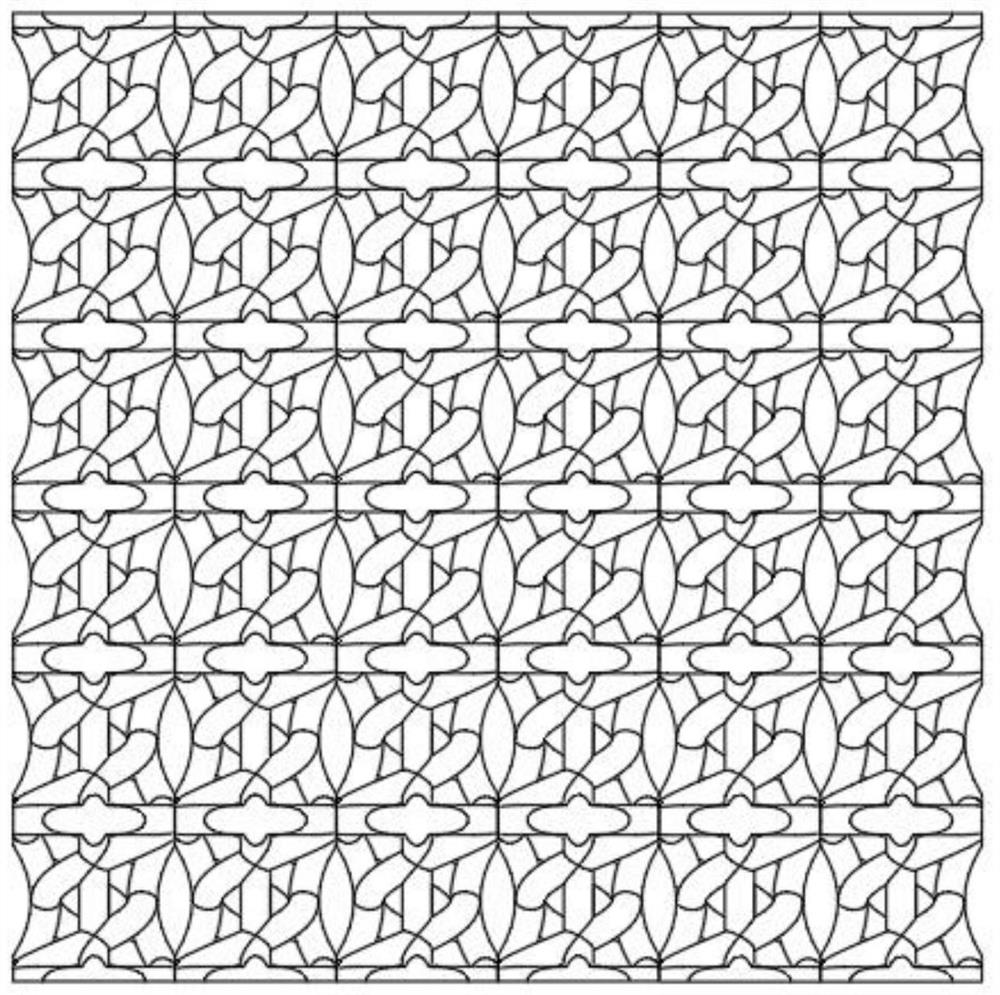

[0058] Example 3: Tetractive spring type single cells and dot matrix structure

[0059] like Figure 5 , Image 6 As shown: Each point of the cell element includes four arcuate support rods, four spiral links. The detailed implementation process is as follows: Use three-dimensional modeling software CATIAV5, in parallel at the middle of the XOY planes in each of the four sides of the XOY plane, (2.5, 0, 5)) At the same time, a circle having a diameter of 5 mm is established on both planes.

[0060] Create a point (1.5, 0, 0.5), and the curve connection is performed on three points (2.5, 0, 5), (1.7, 0, 2.5) to obtain an arcuate support rod to make it curved The support rod is reduced relative to the two plunge cell radians, and the other curved support rod can be obtained. With the contour of the curved support, the point (2.5, 0, 0) is the starting point, the extension shaft is a z-axis, the pitch is 20 mm, and the direction is counterclockwise, establishes a spiral rod, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com