High-density interconnection system packaging device and manufacturing method thereof

A technology for interconnecting systems and packaging devices, applied in the field of semiconductor products, can solve the problem of transmission line being unable to guarantee line width and line spacing, and high cost, and achieve the effect of increasing wire density, increasing wiring density, and increasing layout quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

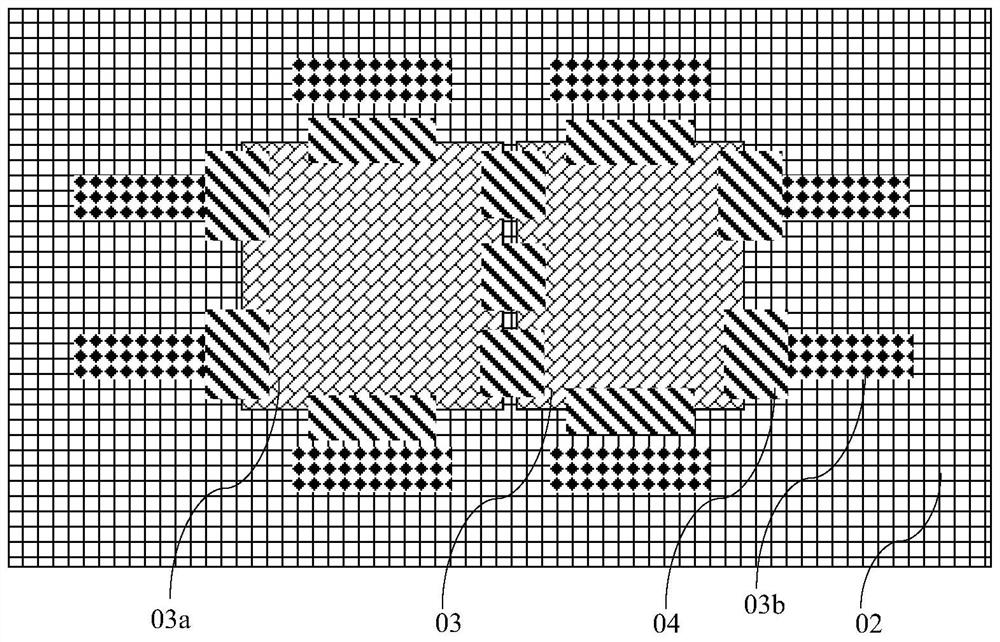

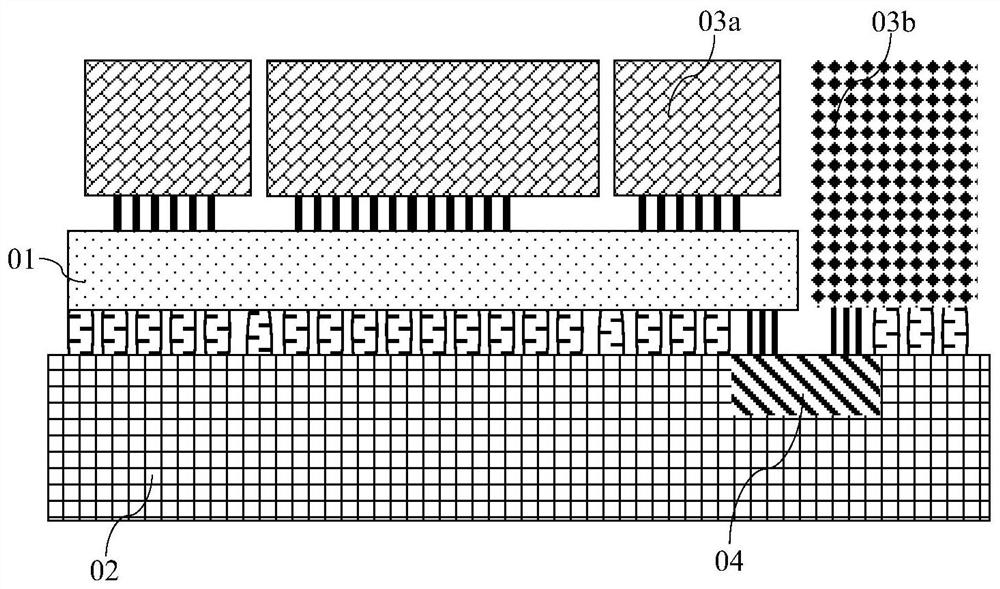

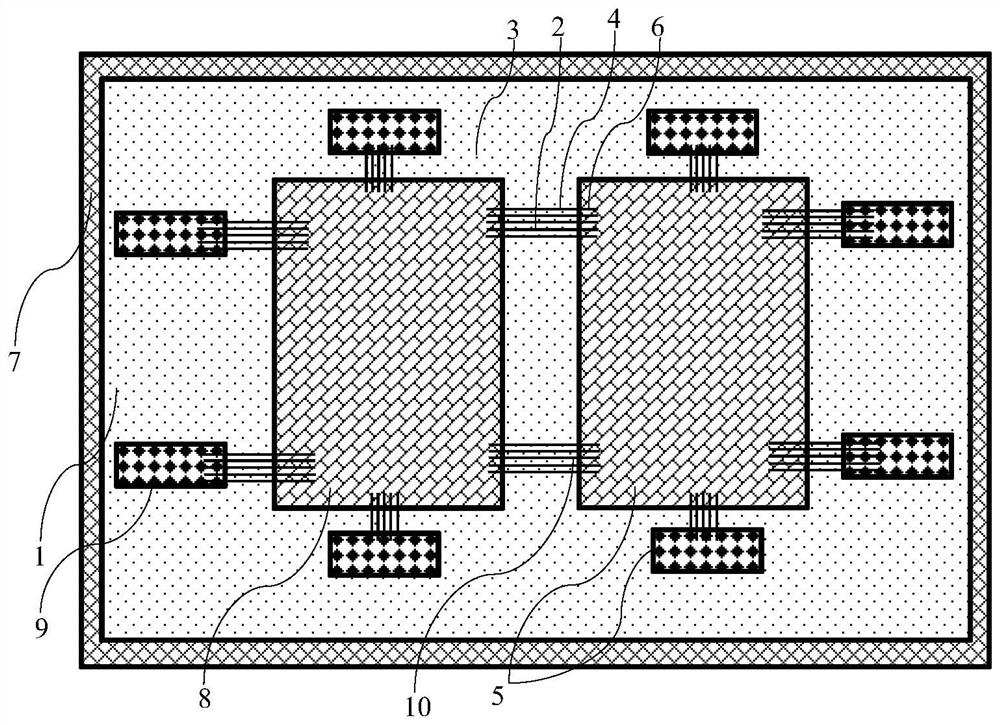

[0063] refer to Figure 2A and Figure 2B As shown, the packaged device of the high-density interconnection system provided by the present invention includes: a high-density wire-planted circuit board 1, which is implanted into a prepreg 3 by using a wire 2 and then heated and pressurized so that the glue of the prepreg is cured to form a high-density wire-planted circuit board 1. The wire 2 has a terminal 4. The chip 5 is arranged on the high-density wiring circuit board 1, and the connecting pin 6 of the chip is connected with the terminal 4 of the wire.

[0064] The line width of the outline dimension of the wire is less than or equal to 2 μm, and the minimum value of the line distance between two adjacent wires can be less than or equal to 2 μm. The meaning of the line width of the outline dimension is the diameter of the circle that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com