Potassium monopersulfate microencapsulated compound disinfectant and production process thereof

A technology of potassium monopersulfate and production process, applied in the directions of disinfectants, biocides, animal repellents, etc., can solve the problems of irritating products, strong sensitivity, secondary pollution, etc., and achieve no toxic side effects , less irritating, less caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

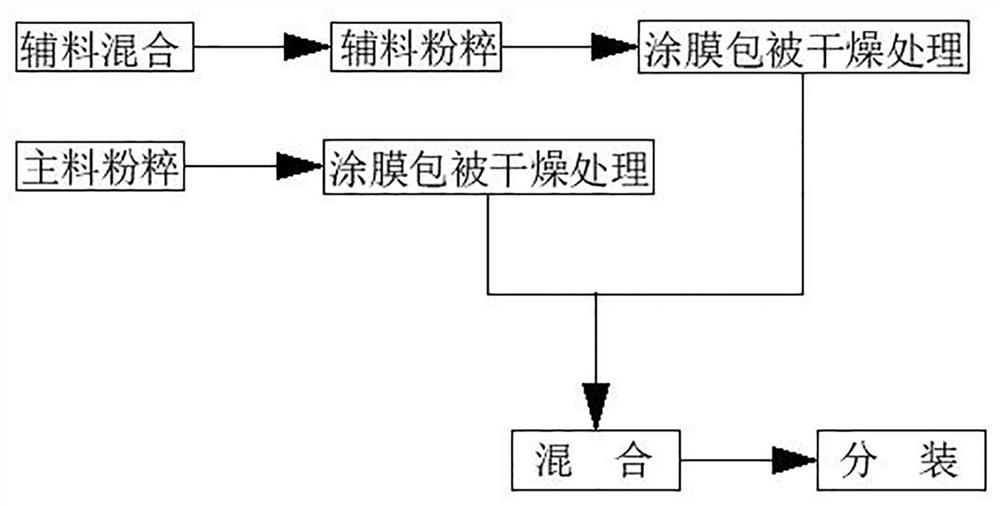

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides the following technical solutions: potassium monopersulfate compound disinfectant, potassium monopersulfate microencapsulated compound disinfectant, composed of main materials and auxiliary materials, wherein the main material is potassium monopersulfate compound Salt and auxiliary materials are mainly composed of bromine-containing compounds, stabilizers, osmotic diffusion agents, fillers, colorants, flavors, and coating agents. Preferably, 10-60 parts of potassium monopersulfate compound salt, 1-70 parts of bromine-containing compound, 10-30 parts of stabilizer, 1-5 parts of osmotic diffusion agent, 5-30 parts of filler, and 0.1-0.5 parts of colorant 0.2-1 part of essence, 0.5-3 parts of film coating agent.

[0029] Specifically, according to the following parts by weight, 40 parts of potassium monopersulfate compound salt in the present embodiment, 40 parts of bromine-containing compound, 20 parts of stabilizer, 2 parts of osmotic diffusion a...

Embodiment 2

[0056] Embodiment 2 is basically the same as the technical scheme of embodiment 1, and its difference is: 20 parts of potassium monopersulfate compound salts in embodiment 2, 40 parts of bromine-containing compounds, 15 parts of stabilizing agents, 5 parts of permeation diffusion agents , 30 parts of filler, 0.4 part of colorant, 1 part of flavor, 0.5 part of film coating agent.

Embodiment 3

[0058] Embodiment 3 is basically the same as the technical scheme of embodiment 1, and its difference is: 10 parts of potassium monopersulfate compound salts in embodiment 3, 1 part of bromine-containing compound, 10 parts of stabilizing agent, 1 part of penetration diffusion agent , 5 parts of filler, 0.1 part of colorant, 0.2 part of flavor, 0.5 part of film coating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com