Preparation process of polyaluminum chloride coagulant for purifying wastewater

A technology for the preparation of polyaluminum chloride, applied in the direction of aluminum chloride, aluminum halide, aluminum compounds, etc., can solve the problems of single coagulant function, high COD concentration, complex wastewater components, etc., and achieve increased degradation and flocculation effects , Wide range of applications, high comprehensive processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation process of polyaluminum chloride coagulant for purifying waste water comprises the following steps:

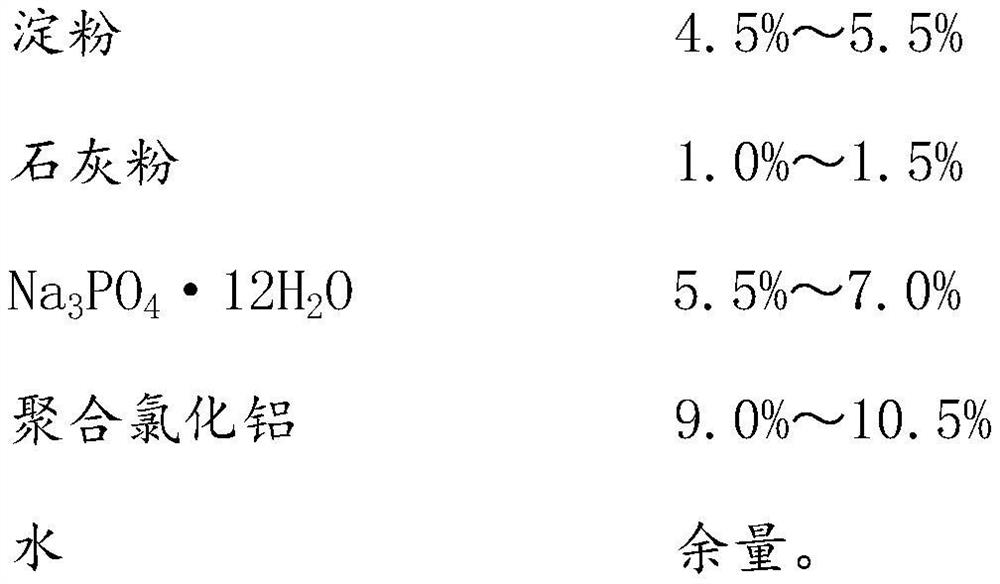

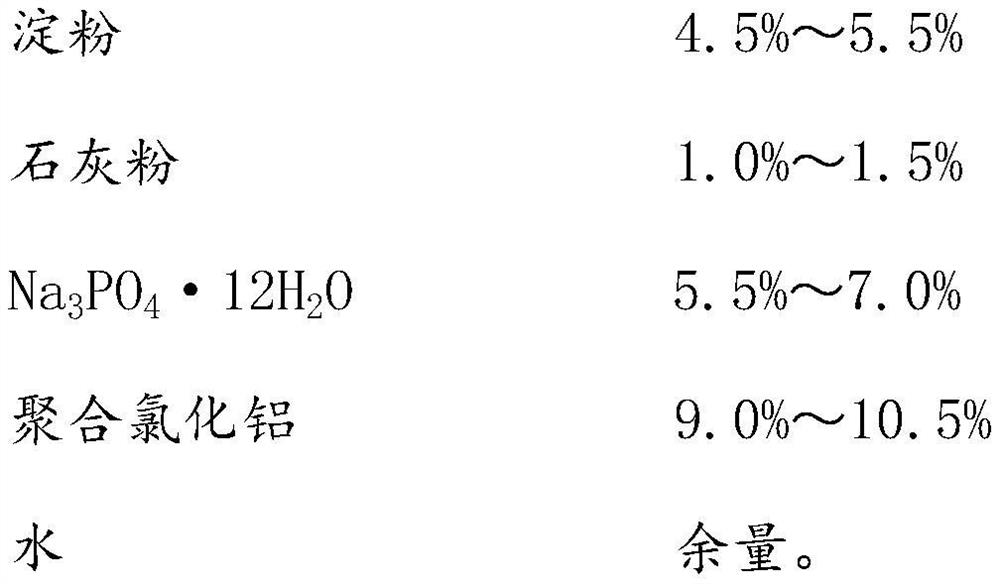

[0026] Taking the preparation of 1000kg of coagulant as an example, add 770kg of water to the stirred reactor, add 90kg of polyaluminium chloride under stirring, and add 55kg of Na 3 PO 4 12H 2 O as a stabilizer, add 10kg of lime powder, stir for 30min, then add 45kg of starch, stir evenly, the above stirring reaction temperature is controlled at 55°C, and the stirring speed is 40r / min, after stirring evenly, add 30kg of crystallized glucose, at 40 Stir and react at ~50°C for 1-3 hours to obtain a coagulant.

Embodiment 2

[0028] A preparation process of polyaluminum chloride coagulant for purifying waste water comprises the following steps:

[0029] Taking the preparation of 1000kg of coagulant as an example, add clear water to the stirred reactor, add 750kg of water, add 97.5kg of polyaluminium chloride under stirring, and add 62.5kg of Na 3 PO 4 12H 2 O as stabilizer, add 12.5kg lime powder, stir 30min, then add starch 50kg, stir evenly, the above stirring reaction temperature is controlled at 55 ℃, and stirring speed is 40r / min, after stirring evenly, add crystalline glucose 28kg, in Stir and react at 40-50°C for 1-3 hours to obtain a coagulant.

Embodiment 3

[0031] A preparation process of polyaluminum chloride coagulant for purifying waste water comprises the following steps:

[0032] Taking the preparation of 1000kg of coagulant as an example, add 729kg of water to the stirred reactor, add 105kg of polyaluminum chloride under stirring, and add 70kg of Na 3 PO 4 12H 2 O as stabilizer, add 15kg lime powder, stir 30min, then add starch 55kg, stir evenly, the above stirring reaction temperature is controlled at 55 ℃, and stirring speed is 40r / min, after stirring evenly, add crystalline glucose 26.25kg, in Stir and react at 40-50°C for 1-3 hours to obtain a coagulant.

[0033] The coagulant obtained above can be used in the coagulation step of sewage treatment such as antibiotic waste water and heavy metal polluted waste water, and the application effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com