Quartz nozzle and preparation process thereof

A preparation process, quartz technology, applied in the field of ceramics, can solve the problems of frequent replacement, short service life, over-speeding of pouring mud settlement, etc., to achieve the effects of improving production efficiency, increasing service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

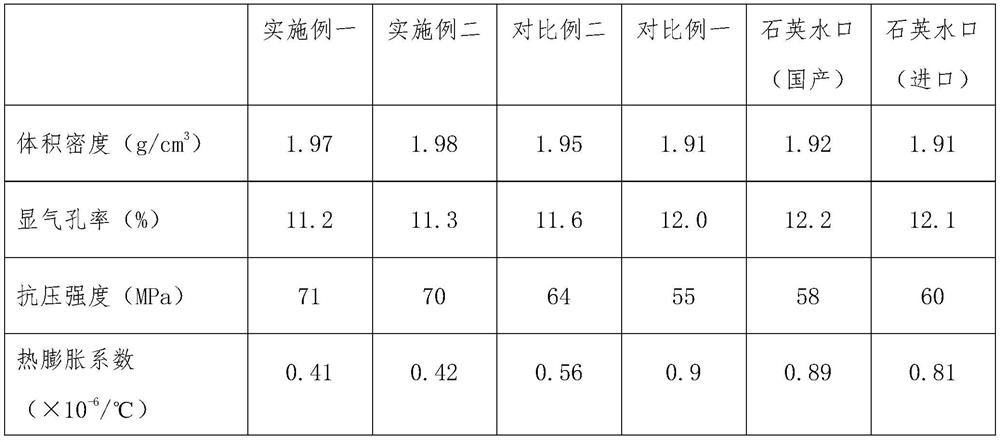

Examples

Embodiment 1

[0020] A preparation process for a quartz nozzle is provided in Embodiment 1 of the present invention, comprising the following steps:

[0021] The first step: to make quartz slurry, put quartz sand and water into a ball mill equipped with ball stones in a ratio of (3-4): 1, and perform ball milling for 20-30 hours to obtain quartz grinding slurry, in which quartz sand is molten Quartz sand in the state of 30-50 mesh or 100-200 mesh or 300-400 mesh in particle size; directly feed quartz sand with particle size of 300-400 mesh, dispersant, ceramic adhesive, inorganic fiber Stir according to the ratio of 200:(100-150):1:(1-2):(40-50) to obtain quartz slurry.

[0022] Among them, the diameter of the inorganic fiber is 80-200um, and the length is 40-100mm. Alumina, silicon carbide, silicon dioxide, carbon, etc. can be selected, and one or more of them can be used in combination. The timing of adding is ball milling of slurry. And after the high-speed stirring stage, specifically,...

Embodiment 2

[0028] A preparation process for a quartz nozzle is provided in Embodiment 2 of the present invention, comprising the following steps:

[0029] The first step: making a gel system, using low-toxic N,N'-dimethylacrylamide as a monomer, N,N'-methylenebisacrylamide as a crosslinking agent, and ammonium persulfate as an initiator. According to monomer, cross-linking agent, initiator, water in the ratio of (20-60): (1-3): (1-2): 400 to prepare a gel system.

[0030] The second step: to make quartz slurry, put quartz sand and water into a ball mill equipped with ball stones in a ratio of (3-4): 1, and perform ball milling for 20-30 hours to obtain quartz grinding slurry, in which quartz sand is molten Quartz sand in the state of 30-50 mesh or 100-200 mesh or 300-400 mesh in particle size; directly feed quartz sand with particle size of 300-400 mesh, gel system, dispersant, ceramic adhesive The agent and the inorganic fiber are stirred according to the ratio of 200:(100-150):(30-40)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com