Industrial lubricant and production process thereof

A technology for industrial lubricants and penetrants, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of low ship function, poor anti-corrosion and anti-rust functions, and great metal influence, and achieve enhanced anti-corrosion performance. , Enhance the effect of anti-oxidation and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

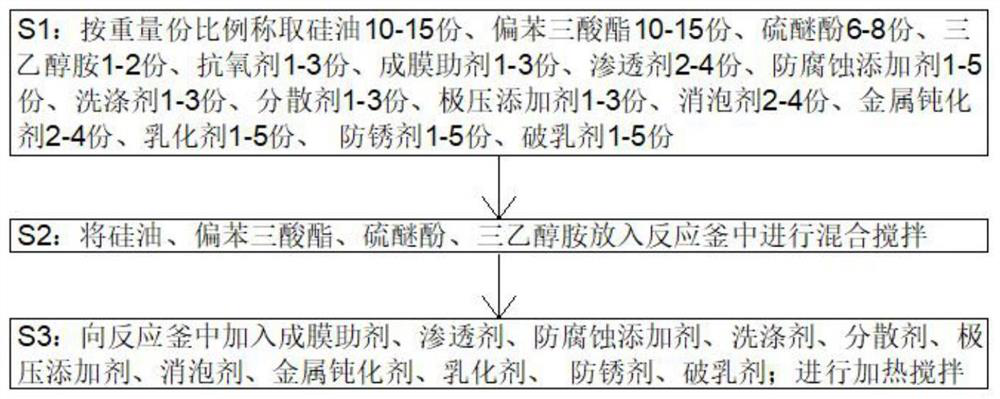

[0023] see figure 1 , in an embodiment of the present invention, an industrial lubricant and its production process, comprising the following components in parts by mass: 10-15 parts of silicone oil, 10-15 parts of trimellitate, 6-8 parts of thioetherphenol, triethanolamine 1-2 parts, 1-3 parts of antioxidant, 1-3 parts of film-forming aid, 2-4 parts of penetrating agent, 1-5 parts of anti-corrosion additive, 1-3 parts of detergent, 1-3 parts of dispersant , Extreme pressure additive 1-3 parts, defoamer 2-4 parts, metal deactivator 2-4 parts, emulsifier 1-5 parts, demulsifier 1-5 parts.

[0024] Preferably, 1-5 parts of antirust agent are also included.

[0025] Preferably, the silicone oil is one or more of methyl silicone oil, ethyl silicone oil, phenyl silicone oil, methylphenyl silicone oil, methylchlorophenyl silicone oil, methyl ethoxy silicone oil, and methyl hydroxy silicone oil.

[0026] Preferably, the antioxidant is composed of polyphosphate, orthophosphate and fa...

Embodiment 2

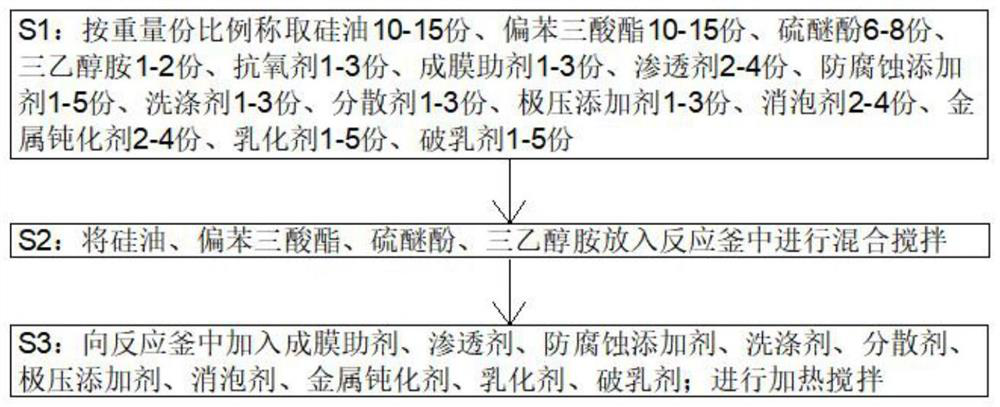

[0037] see figure 2 , in an embodiment of the present invention, an industrial lubricant and its production process, comprising the following components in parts by mass: 10-15 parts of silicone oil, 10-15 parts of trimellitate, 6-8 parts of thioetherphenol, triethanolamine 1-2 parts, 1-3 parts of antioxidant, 1-3 parts of film-forming aid, 2-4 parts of penetrating agent, 1-5 parts of anti-corrosion additive, 1-3 parts of detergent, 1-3 parts of dispersant , Extreme pressure additive 1-3 parts, defoamer 2-4 parts, metal deactivator 2-4 parts, emulsifier 1-5 parts, demulsifier 1-5 parts.

[0038] Preferably, the silicone oil is one or more of methyl silicone oil, ethyl silicone oil, phenyl silicone oil, methylphenyl silicone oil, methylchlorophenyl silicone oil, methyl ethoxy silicone oil, and methyl hydroxy silicone oil.

[0039] Preferably, the antioxidant is composed of polyphosphate, orthophosphate and fatty acid salt.

[0040] Preferably, the penetrating agent is one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com