A kind of preparation method of wear-resistant alloy material

A technology of wear-resistant alloy and manganese alloy is applied in the field of preparation of wear-resistant alloy materials, which can solve the problems of long production process and large material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

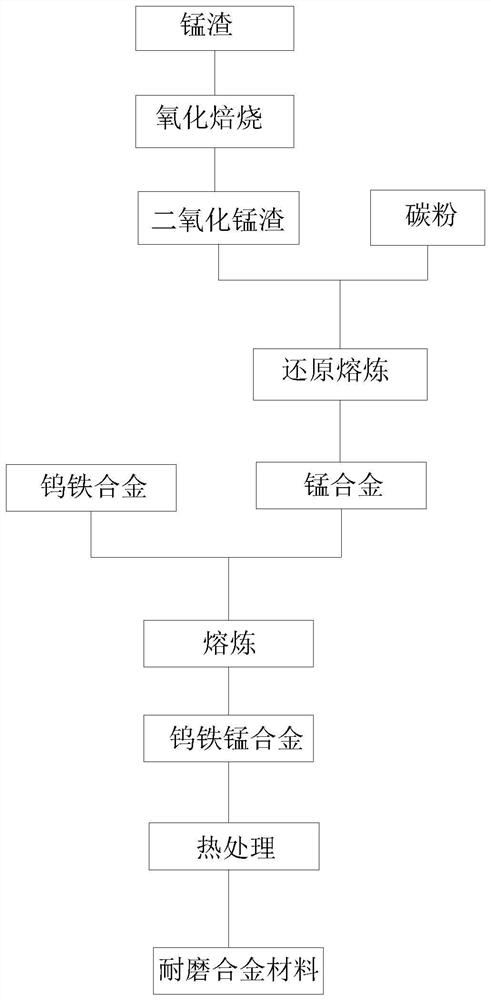

[0024] The embodiment of the present invention specifically provides a method for preparing a wear-resistant alloy material in view of the technical problems that the current wet extraction of manganese leads to a long production process and a large material consumption for the production of wear-resistant alloy materials, wherein the method includes:

[0025] The manganese slag is heated in an aerobic environment to obtain a solid slag rich in manganese dioxide;

[0026] adding carbon powder or ferrosilicon alloy to the solid slag rich in manganese dioxide, and after high temperature reduction smelting, a manganese alloy is obtained;

[0027] After mixing the manganese alloy and the ferrotungsten alloy according to the set ratio, a premix is obtained, and the premix is smelted at a high temperature to obtain the ferrotungsten manganese alloy;

[0028] The tungsten-ferromanganese alloy is poured into a mold to form a blank, and the wear-resistant alloy material is obtained...

Embodiment 1

[0040] The preparation method of the wear-resistant alloy material in this embodiment includes the following steps:

[0041] The tungsten iron alloy composition contains 8.34% tungsten and 91.45% iron. The manganese slag was roasted with oxygen to obtain solid slag rich in manganese dioxide, and the manganese alloy was prepared by carbothermic reduction at 1650°C. The ferrotungsten alloy and the manganese alloy obtained respectively are smelted at a ratio of 5:1 to obtain the ferrotungsten manganese alloy, and the smelting temperature is 1450°C, and the ferrotungsten manganese alloy is poured into a mold to form a blank. The blank is calcined at a high temperature of 1100°C for 1 hour, and then a wear-resistant liner can be prepared after quenching. The obtained ball mill liner material has high hardness and good wear resistance, and the surface of the material reaches 582 Brinell hardness.

Embodiment 2

[0043] The preparation method of the wear-resistant alloy material in this embodiment includes the following steps:

[0044] The tungsten-ferrous alloy composition contains 9.21% tungsten and 89.45% iron. The manganese slag was roasted with oxygen-rich to obtain solid slag rich in manganese dioxide, and the manganese alloy was prepared by carbothermic reduction at 1600°C. The ferrotungsten alloy and the manganese alloy obtained respectively are smelted at a ratio of 6:1 to obtain a ferrotungsten manganese alloy, and the smelting temperature is 1500°C, and the ferrotungsten manganese alloy is poured into a mold to form a blank. The blank is calcined at a high temperature of 1150°C for 2 hours, and then a wear-resistant liner can be prepared after quenching. The obtained ball mill liner material has high hardness and good wear resistance, and the surface of the material reaches 593 Brinell hardness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com