Inclined shaft plunger type hydraulic motor pump

A hydraulic motor and inclined shaft column technology, applied in the field of hydraulic pumps, can solve the problems of large structural size and inconvenient maintenance of motor pumps, and achieve the effects of convenient follow-up maintenance, small overall size and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

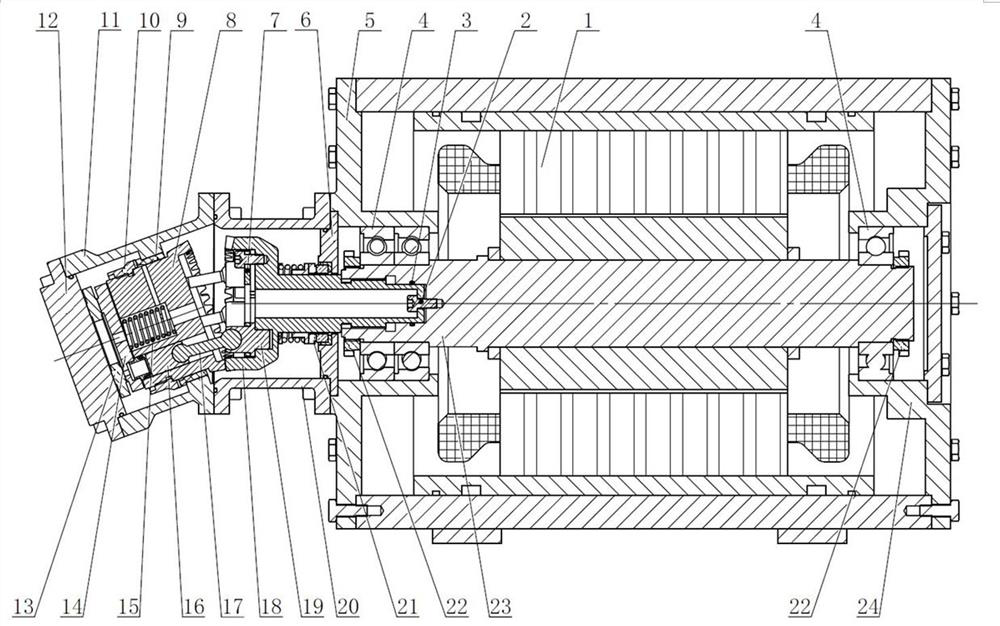

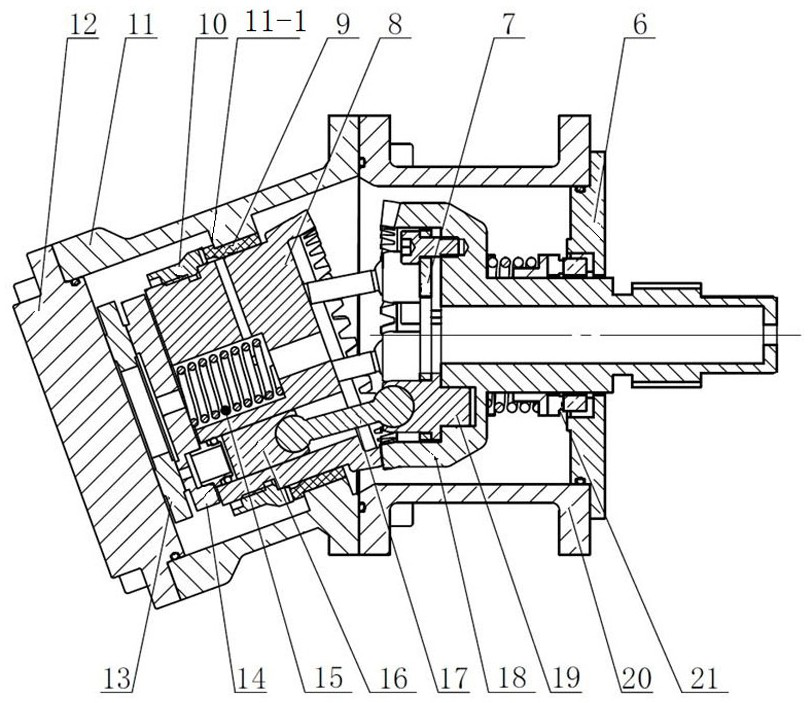

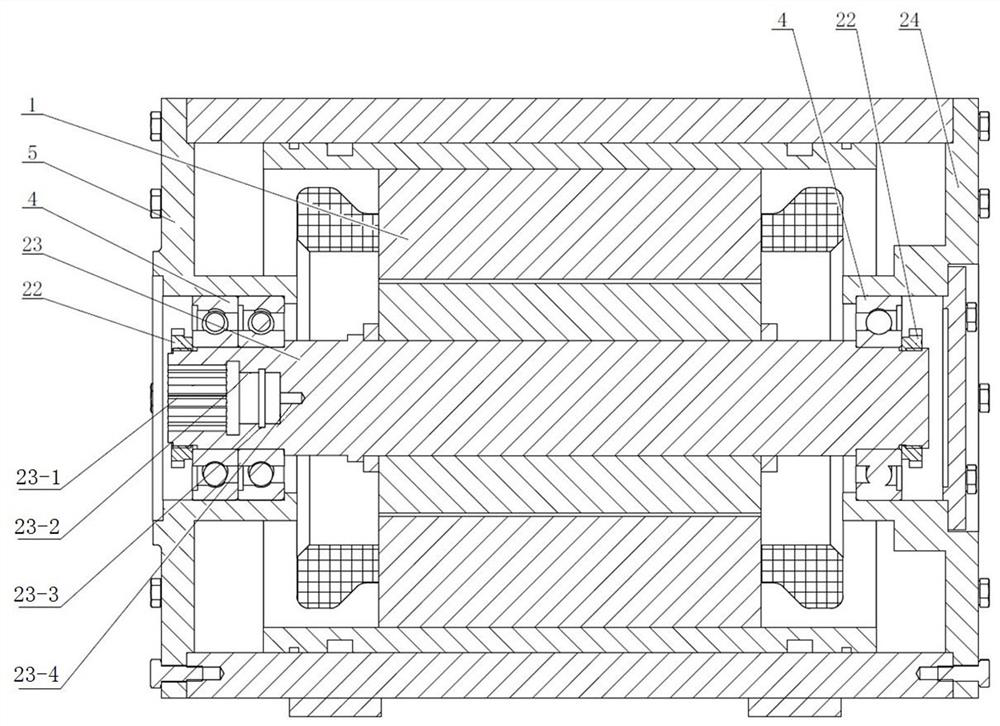

[0042] like Figure 1 to 9 As shown, the scalp shaft plunge hydraulic motor pump (hereinafter referred to as the motor pump) mainly includes a bevel shaft pump assembly and a motor.

[0043] The structure of the bevel shaft pump assembly is like figure 2 as well as Figure 4 to 9 As shown, the oblique shaft pump assembly includes a pump end cap 12, a housing 11, a straight housing 20, a pump end cap 12, a straight housing 20, a straight housing 20, a pump end cap 12, a straight housing 20, and a straight housing 20, and a straight housing 20. The distribution disc 13 is fixed to the right side of the pump end cover 12, and the distribution tray 13 forms a whole with the pump end cap 12. The cylinder 8 is mounted in the housing 11, in particular, the sliding bearing 9 is mounted in the outside of the cylinder 8, the sliding bearing 9 is fitted to the outer peripheral surface of the cylinder 8, and the support cylinder 8 is rotated. At the interior section of the oblique housing 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com