Crystallizer with separation and collapse prevention functions

A crystallizer and functional technology, applied in the field of solid particle crystallization, can solve the problems of small application range and poor purification effect, and achieve the effect of inconvenient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

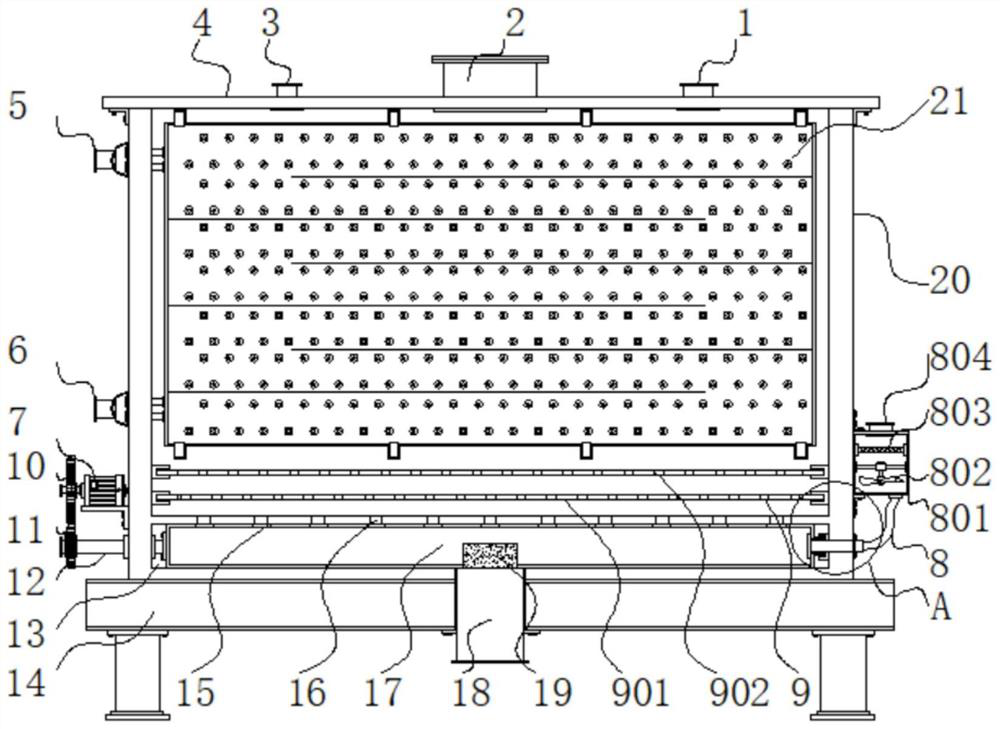

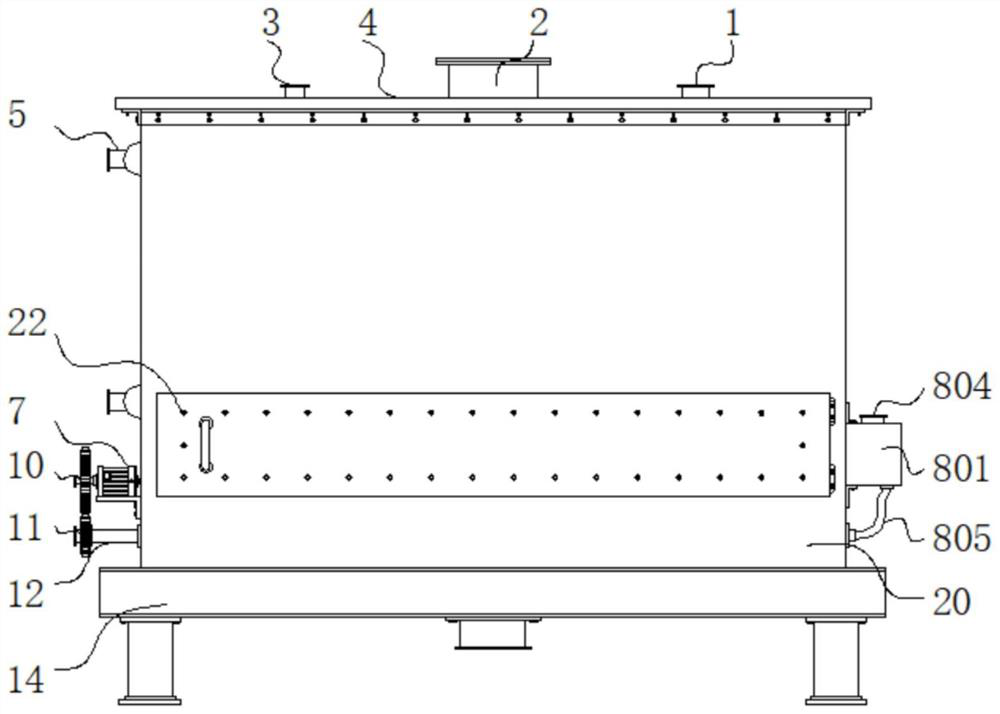

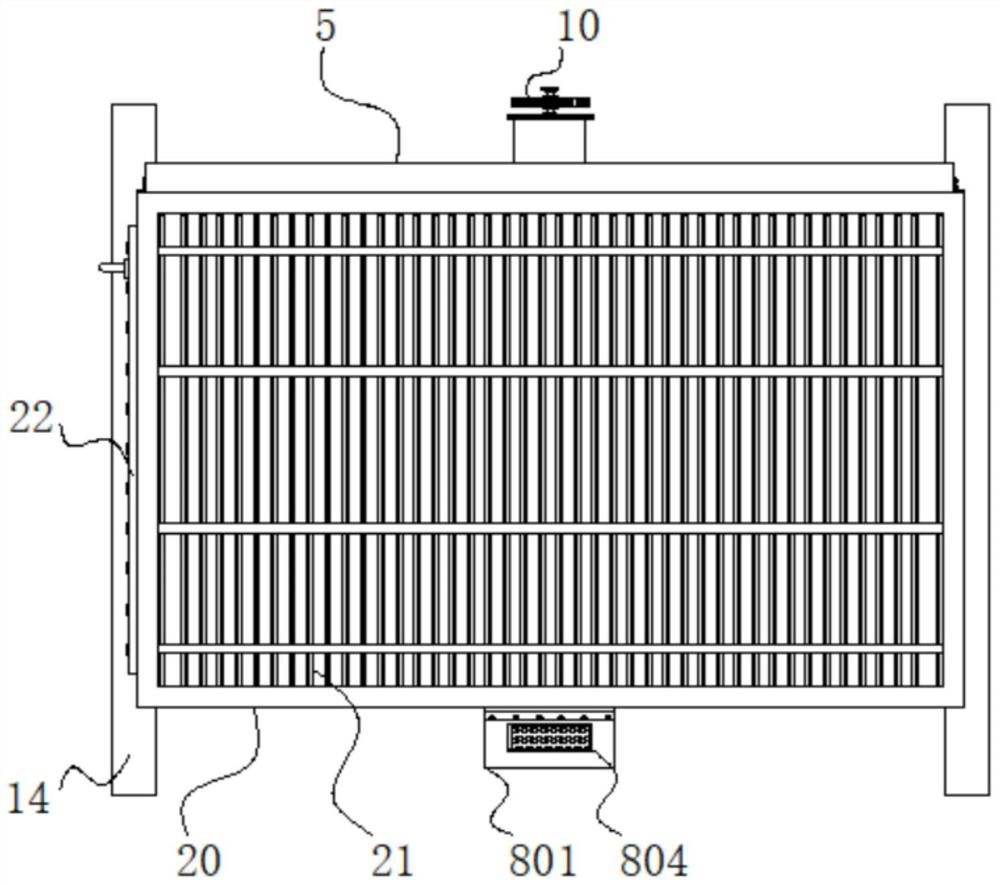

[0021] Example 1: See Figure 1-5 An isolated and anti-collapse function having a crystallizer, comprising a chassis 14, the chassis 14 is mounted to the top case 20, and a position at a center of the inside bottom of the housing 20 defines a cavity 13, 13 is provided with an internal cavity the bottom end of the feed tube 17, and the center position of the lower surface of the feed tube 17 defines a notch 19, at a central position of the bottom end of the inner cavity 13 is provided with a discharge tube 18 and outlet tube 18 extends to the base below 14, the upper surface of the lower feed tube 17 defines a plurality of grooves 15 first holes, and even the bottom inside of the cabinet 20 defines a groove 16 of the second hole, the first hole 15 and a slot 16 a second slot holes a correspondence, and the first groove hole slightly larger than the aperture of the second aperture 15 of the aperture 16 of the groove, the lower side of the feed tube 17 is connected to the pawl 12 and ...

Embodiment 2

[0027] Example 2: Drying oven 801 comprises a structure 8, blower 802, air filter 803, air inlet 804, the hose 805 and the communication pipe 806, communication pipe 806 is fixed to the lower side of the housing 20, and the oven settings 801 on the box body side communication pipe 80620, oven 801 provided with a top air inlet 804, and 801 inside the oven air filter 803 is mounted transversely, the oven interior 801 below the air filter 803 is mounted with a transverse fan 802, and the bottom side 801 of the hose 805 is connected to the oven;

[0028] One end of the communication pipe 806 through the feed box 20 and the lower side of the tube 17 extends to the interior of the cutting tube 17, and the bottom end of the hose 805 is connected to the communicating pipe 806;

[0029] Diameter drive gear 10 is larger than the diameter of the driven gear 11 and the driven gear 11 and drive gear 10 are connected by a rodent;

[0030] Specifically, such as figure 1 , figure 2 , image 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com