Axial stirring type mixed discharging device for composite coating and working method

A discharge device and composite coating technology, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of short adaptation period of two-component coatings, difficulty in cleaning equipment, and inability to continue normally Work and other issues, to achieve the effect of high construction efficiency, close connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

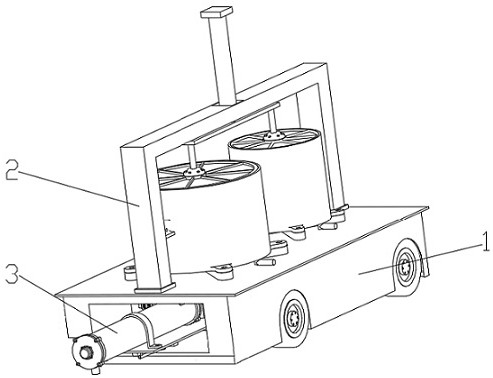

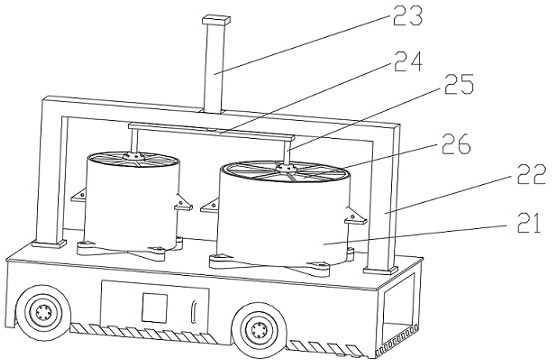

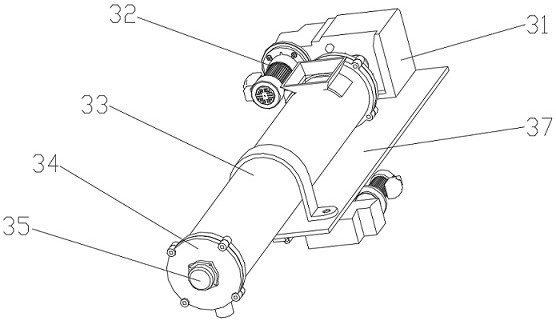

[0021] Such as Figure 1 to Figure 5 As shown, a composite coating axial stirring type mixing and discharging device of the present invention comprises: a transport platform 1, a discharging device 2, and an agitating mixing and discharging device 3; the barrel 21 of the discharging device 2 is fixedly mounted on On the transport platform 1; the agitating mixing and unloading device 3 is fixedly installed in the rear-end working box of the transport platform 1; the discharging device 2 includes: a barrel 21, a hydraulic cylinder bracket 22, a telescopic hydraulic cylinder 23. Binder plate 24, binder column 25, and binder plate 26; the agitating mixing and unloading device 3 includes: reducer I31, motor I32, mixing unloading cylinder 33, flange plate 34, bearing with seat 35, Screw rod 36 , swing base mechanism 37 ; said swing base mechanism 37 includes: reducer II 371...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com