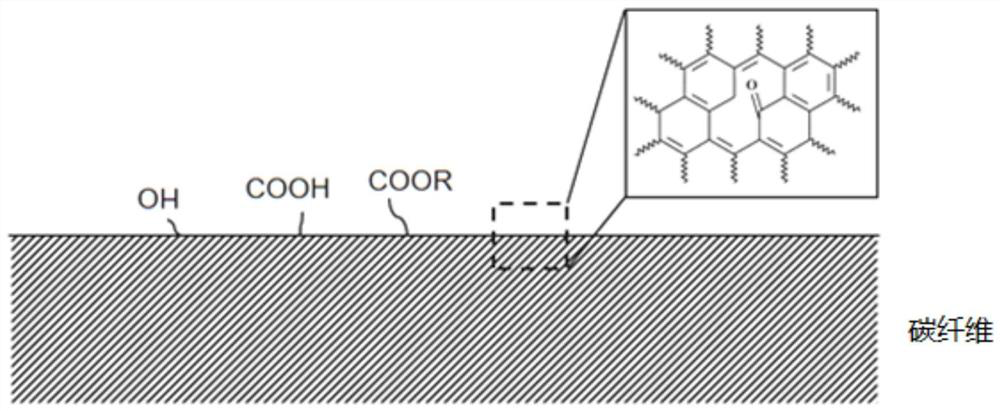

Carbon fiber reinforced ultra-high performance concrete and preparation method thereof

An ultra-high performance, carbon fiber technology, applied in the field of building materials, can solve the problems of corrosion of steel fibers, low utilization rate, shortened service life of components, etc., to achieve the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

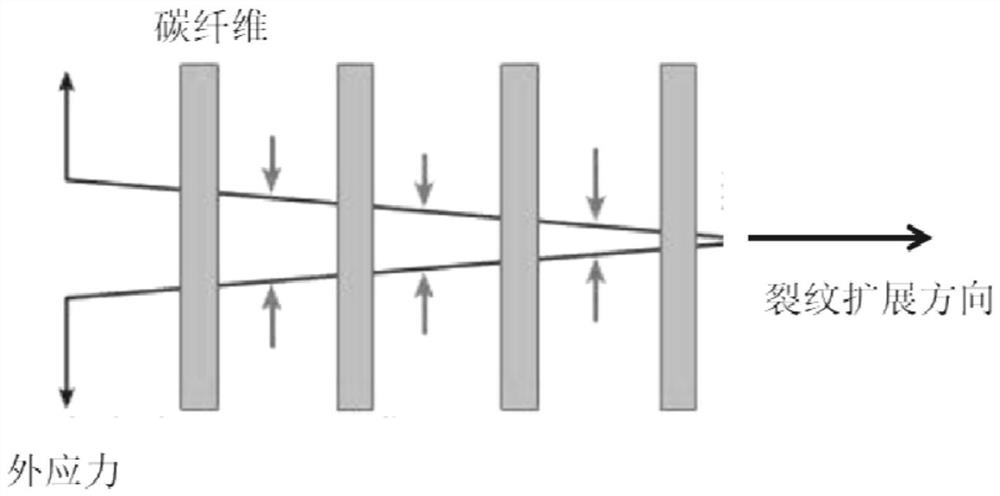

Method used

Image

Examples

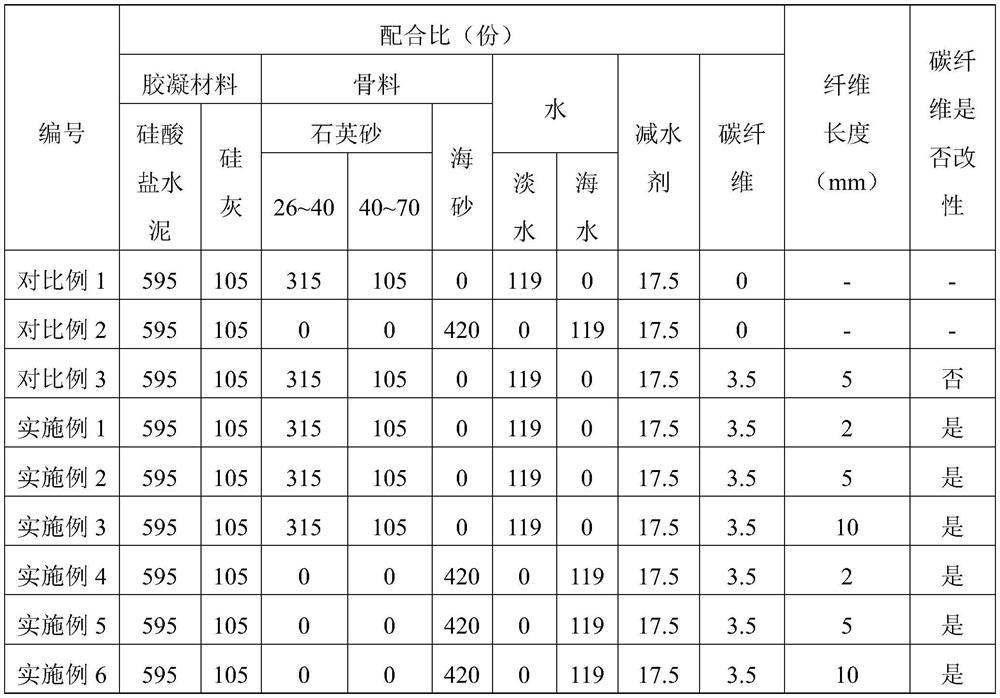

Embodiment 1

[0037] Embodiment 1: In this embodiment, on the basis of the mixing ratio of Comparative Example 1, PAN-based modified carbon fibers with a fiber length of 2 mm are added, and the carbon fiber content accounts for 0.28% of the total mass (accounting for about 0.5% of the total volume). Stirring, molding and maintenance are carried out according to the requirements of the present invention.

Embodiment 2

[0038] Embodiment 2: In this embodiment, on the basis of the mixing ratio of Comparative Example 1, PAN-based modified carbon fibers with a fiber length of 5 mm are added, and the carbon fiber content accounts for 0.28% of the total mass (accounting for about 0.5% of the total volume). Stirring, molding and maintenance are carried out according to the requirements of the present invention.

Embodiment 3

[0039] Embodiment 3: In this embodiment, on the basis of the mixing ratio of Comparative Example 1, PAN-based modified carbon fibers with a fiber length of 10 mm are added, and the carbon fiber content accounts for 0.28% of the total mass (accounting for about 0.5% of the total volume). Stirring, molding and maintenance are carried out according to the requirements of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com