Mixed dispersing agent for modified ammonium nitrate fuel oil explosive and preparation method of mixed dispersing agent

A technology of ammonium oil explosives and dispersants, which is applied in the field of mixed dispersants for modified ammonium oil explosives and its preparation, which can solve the problems of modified ammonium oil explosives, which are prone to moisture, agglomeration, hardening, swelling, unevenness, etc., and achieve improved dispersion Ability and uniformity, good fluidity, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

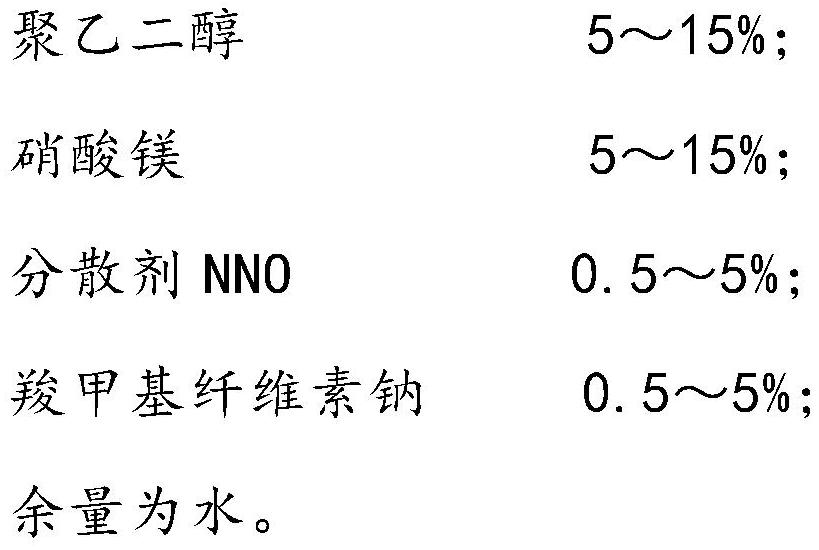

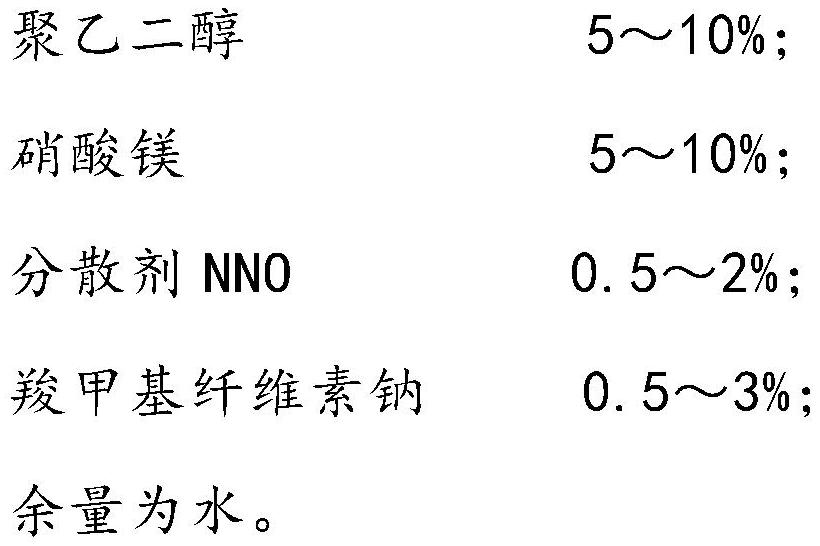

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of mixed dispersant is as follows:

[0022] Add magnesium nitrate to the water and stir for 5min (stirring speed 200r / min), until the magnesium nitrate is completely dissolved, then add polyethylene glycol and stir for 2min (stirring speed 200r / min), until the polyethylene glycol is completely dissolved, then add the diffusing agent NNO, Stir while adding (stirring speed 200r / min), until the diffusion agent NNO is completely dissolved, add sodium carboxymethyl cellulose, stir while adding (stirring speed 200r / min), until sodium carboxymethyl cellulose is completely dissolved, that is A dispersant must be mixed.

Embodiment 1

[0024] Prepare mixed dispersant 1 according to the above-mentioned preparation method, the weight percent of raw material is as follows:

[0025] 10% polyethylene glycol; 10% magnesium nitrate; 2% dispersant NNO; 3% sodium carboxymethyl cellulose; 75% water.

Embodiment 2

[0027] Prepare mixed dispersant 2 according to the above-mentioned preparation method, the weight percent of raw material is as follows:

[0028] Polyethylene glycol 5%; magnesium nitrate 5%; dispersant NNO 0.5%; sodium carboxymethylcellulose 0.5%; water 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com