Unequal-strength beam-column joint based on ring rib confined concrete laminated short column

A technology for constraining concrete and beam-column joints, applied in building reinforcements, structural elements, building components, etc., can solve problems such as the impact of unequal strength beam-column point structural performance, and achieve the goal of reducing construction difficulty, ensuring seismic performance, and eliminating the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

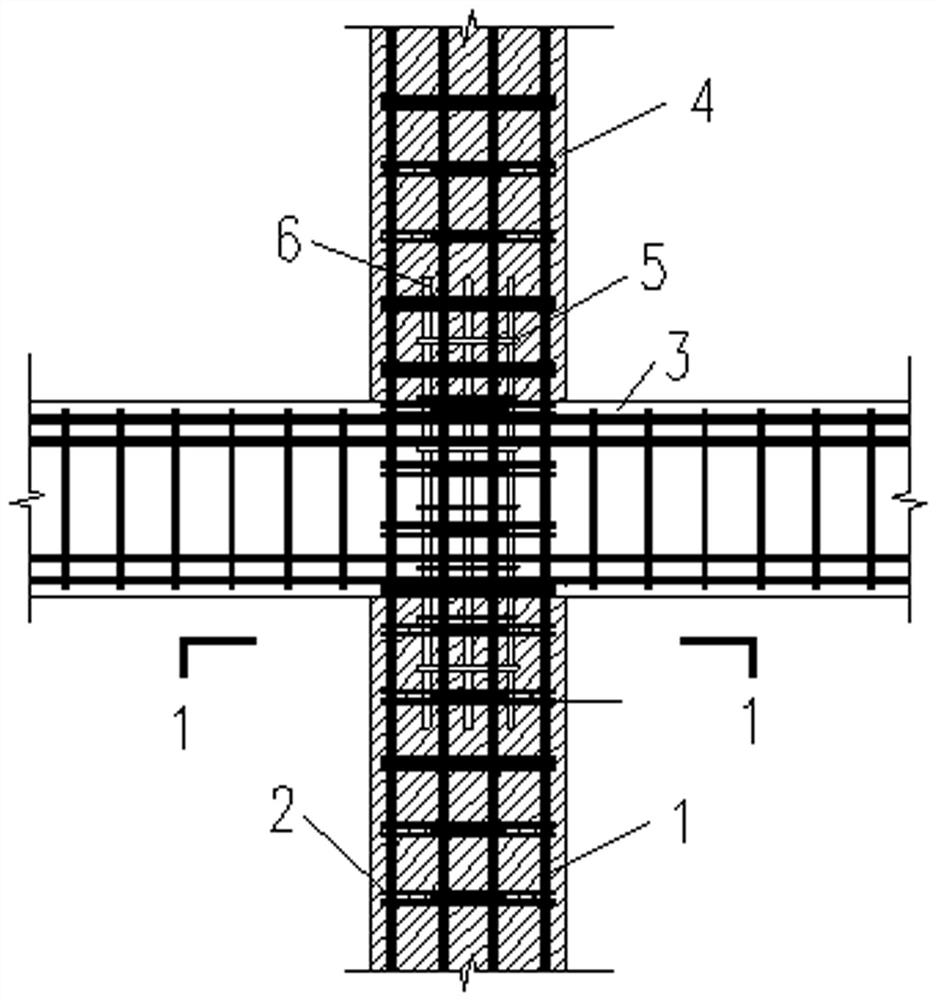

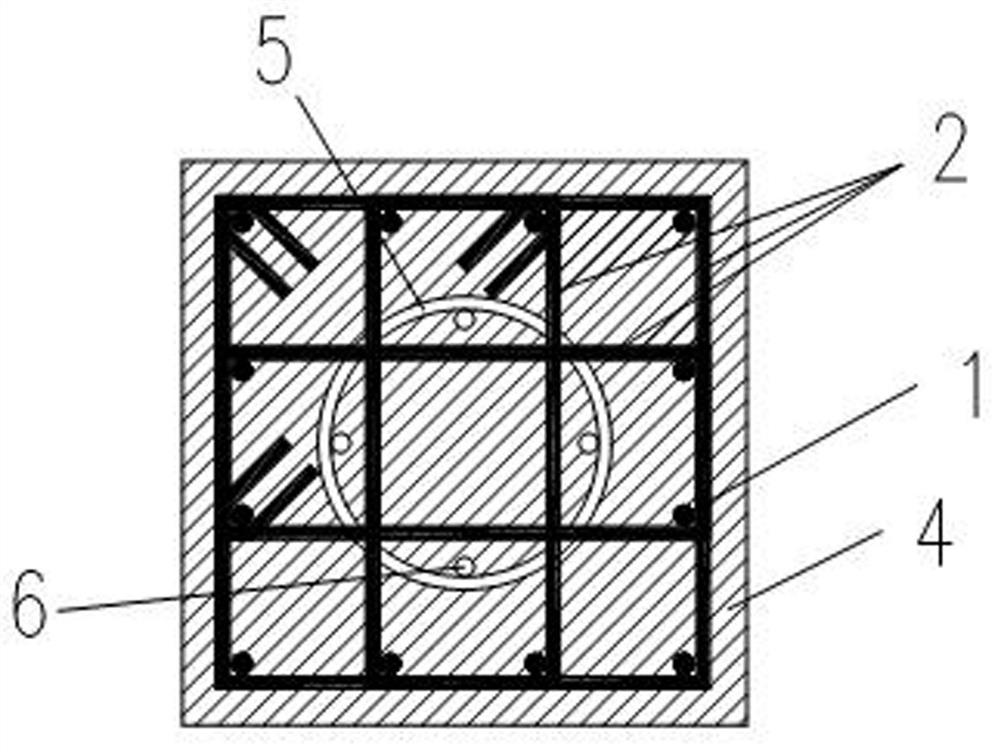

[0030] see Figure 1~4 , a beam-column joint of unequal strength based on the composite short column of reinforced concrete with ring reinforcement, including column longitudinal reinforcement 1, column combined stirrup 2, first-strength grade concrete 3, second-strength grade concrete 4, ring reinforcement 5 and short Longitudinal tendons6.

[0031] The design strength of the high-strength grade concrete 4 is more than two grades higher than the design strength of the low-strength grade concrete 3 . It should be noted that in the field of building construction, the second strength grade concrete 4 is higher strength grade concrete, and the first strength grade concrete 3 is lower strength grade concrete.

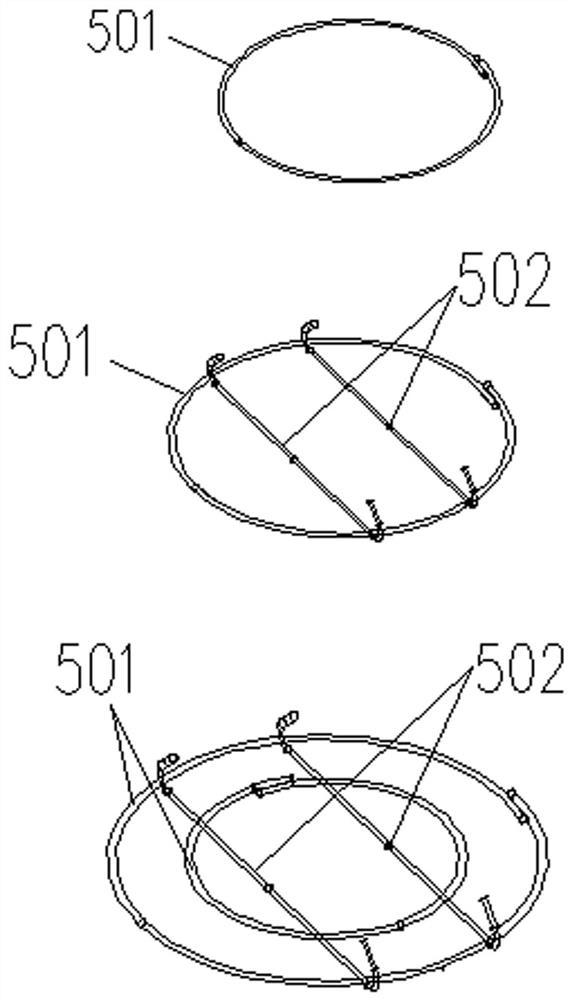

[0032] The ring bars 5 can be made of materials such as low-grade steel, high-performance steel, and high-performance composite materials.

[0033] The overlapping section of the circular rib 501 of the ring rib 5 adopts double-sided lap welding, and the lap length is not...

Embodiment 2

[0036] see Figure 1~4 , a beam-to-column joint of unequal strength based on short concrete laminated columns confined by ring bars, including

[0037] Concrete column, which constitutes the main structure of the beam-column joint, and it is composed of the first strength grade concrete 3 formed by horizontal pouring, and the second strength grade concrete 4 vertically poured on the upper and lower sides of the first strength grade concrete 3 respectively ;

[0038] Column longitudinal reinforcement 1, which is vertically buried inside the concrete column of the beam-column node, and it is provided with several reinforcement cages bound and fixed by column combination stirrups 2 to form columns;

[0039] A composite short column of concrete with ring reinforcement restraint, which is arranged in the reinforcement cage formed by the column longitudinal reinforcement 1 and the column combination stirrup 2 arranged longitudinally, and it is composed of ring reinforcement 5 and s...

Embodiment 3

[0043] A beam-column joint of unequal strength based on a concrete composite short column constrained by ring bars, the construction method of which comprises the following steps:

[0044] Step 1, according to the reinforcement diagram, bind the column longitudinal reinforcement 1, the column combined stirrup reinforcement 2, the ring reinforcement 5 and the short longitudinal reinforcement 6 to form a reinforcement cage for the column, wherein the first ring reinforcement 5 is bound to the column Combine the stirrup 2, and then tie the short longitudinal reinforcement 6 on the ring reinforcement 5.

[0045] Step 2: According to the reinforcement diagram, the slab reinforcement, the beam longitudinal reinforcement, the beam stirrup, the joint core area stirrup, the ring reinforcement 5 and the short longitudinal reinforcement 6 are bound and formed to form the beam slab and the joint core area reinforcement cage.

[0046] Step 3, pouring the second strength grade concrete 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com