FDR method soil temperature and humidity sensor measured value calibration system and construction method thereof

A technology of temperature and humidity sensor and calibration system, which is applied in the direction of neural learning methods, instruments, biological neural network models, etc., can solve the problems of considering and not being able to use accurate soil moisture values, and achieve low power consumption, low long-distance, and improved accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

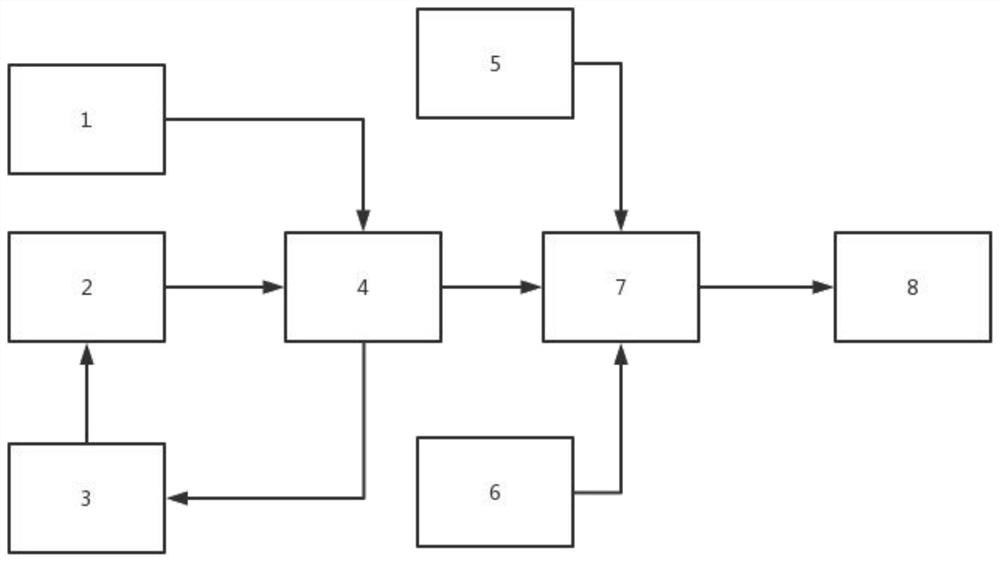

[0053] The FDR method soil temperature and humidity sensor measurement value calibration system of the present embodiment includes a perception layer, a network layer and an application layer, wherein:

[0054] The sensing layer contains four sensors, which are FDR-100 soil temperature and humidity sensor 1, TYD-2 soil hardness sensor 2, CO 2 Sensor 5, light temperature and humidity sensor 6, STM32 microcontroller 4, STM32 microcontroller 4 are respectively connected to FDR-100 soil temperature and humidity sensor 1, TYD-2 soil hardness sensor 2, CO 2 The sensor 5, the light temperature and humidity sensor 6 and the STM32 microcontroller 4 are connected to the corresponding matching Lora sub-nodes in turn through the 485 serial port connection line and the Dupont line. The function of the sensing layer is to collect soil parameter data of the soil, including soil temperature and humidity. , hardness and CO in the environment 2 Concentration and light intensity; the function o...

Embodiment 2

[0060] The construction method of the FDR method soil temperature and humidity sensor measurement value calibration system of the present embodiment, the specific steps are as follows:

[0061] The first step is to establish a small experimental measurement system:

[0062] The small experimental measurement system such as figure 1 As shown in the schematic block diagram of the structure of the small-scale experimental measurement system established by the present invention, it consists of FDR-100 soil temperature and humidity sensor 1, TYD-2 type soil hardness sensor 2, CO 2Sensor 5, light temperature and humidity sensor 6, stepper motor 3, STM32 microcontroller 4, USR-G781 router 7 and cloud monitoring platform 8, FDR-100 soil temperature and humidity sensor 1, TYD-2 type soil hardness sensor 2, stepper The motor 3 is connected to the STM32 single-chip microcomputer 4 respectively, and the TYD-2 type soil hardness sensor 2 is separately connected to the stepping motor 3, an...

Embodiment 3

[0075] The application operation method of the FDR method soil temperature and humidity sensor measurement value calibration system of the present embodiment is as follows:

[0076] The operation steps of this system in practical application mainly include: first, connect the FDR-100 soil temperature and humidity sensor 1 to be calibrated into the STM32 single-chip microcomputer 4 according to the connection mode of the sensing layer described in the above-mentioned embodiment 1, and then connect the CO 2 Sensor 5, light temperature and humidity sensor 6, and TYD-2 type soil hardness sensor 2 are connected to the STM32 single-chip microcomputer 4 through the 485 serial port connection line in turn, and then the sensing layer described in Embodiment 1 is connected to the Lora sub-node, and the system is connected to Power on and turn on the Lora sub-node and Lora concentrator, and then view the calibrated data on the cloud server platform 8, including soil moisture, soil tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com