Speed sensor induction motor vector control speed regulation system

A speed sensor, induction motor technology, applied in the field of power electronics and electric drive, can solve problems such as poor adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

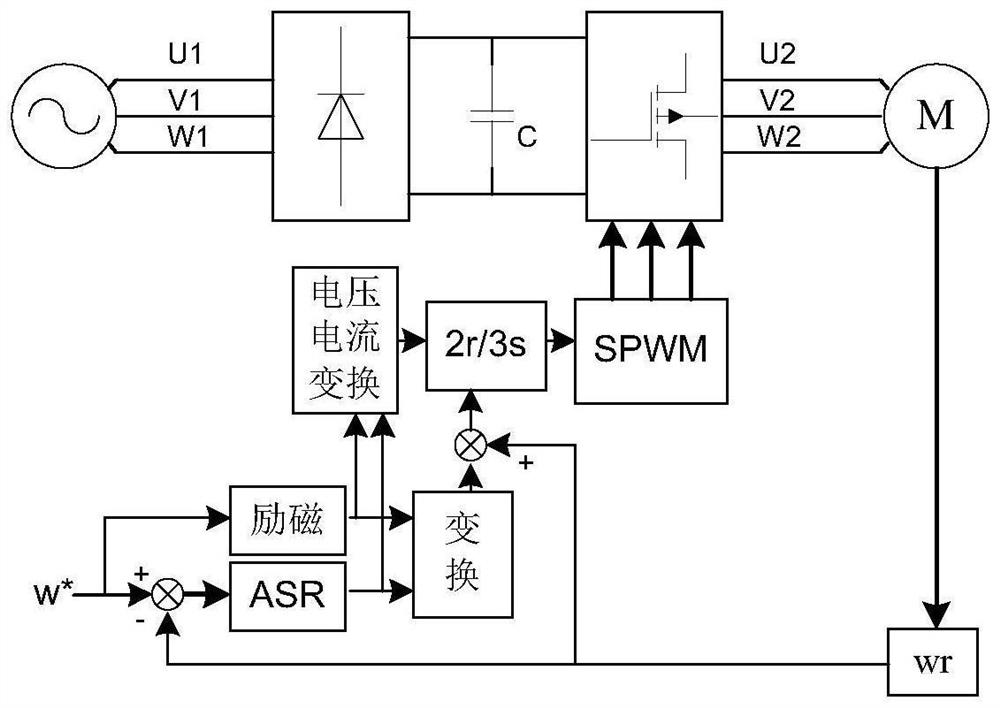

Method used

Image

Examples

Embodiment Construction

[0036] Implementation example:

[0037] The present invention adopts the implementation parameter of speed sensor induction motor vector control speed regulating system as shown in table 1:

[0038] Table 1 Variables and parameter values of speed sensor induction motor vector control speed control system

[0039]

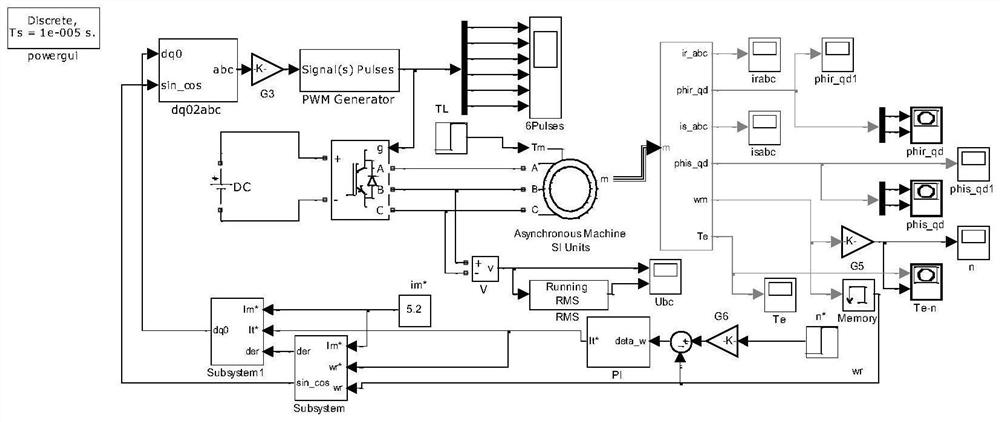

[0040] Through the example parameters in Table 1, the simulation model is established and its operating environment is debugged. Such as image 3 The simulation structure diagram of the speed control system based on the speed sensor vector control system is shown, which includes the inverter power supply structure module, three-phase induction motor, induction motor signal sampling module, induction motor speed regulation feedback module, vector control system module, etc. part. The establishment of this model can verify the high precision and reliability of the speed sensor system.

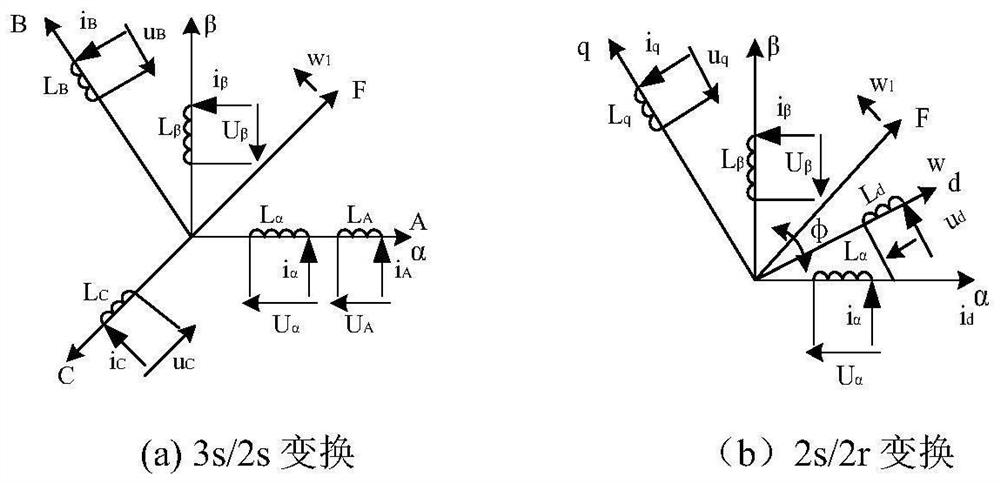

[0041] Such as Figure 4 Shown is the dq axis of two-coordinate transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com